Researchers from Los Alamos Nationwide Laboratory (LANL) have developed a 3D printed perfusion bioreactor (3D-PBR) created to enhance how human bone marrow-derived mesenchymal stem cells (MSCs) develop and differentiate.

With contributions from the College of New Mexico (UNM), the system additionally helps co-culture with vascular cells. Designed to deal with the restrictions of primary cell tradition fashions whereas capturing the complexities of actual tissue environments, this compact system goals to make mobile differentiation research extra sensible and exact.

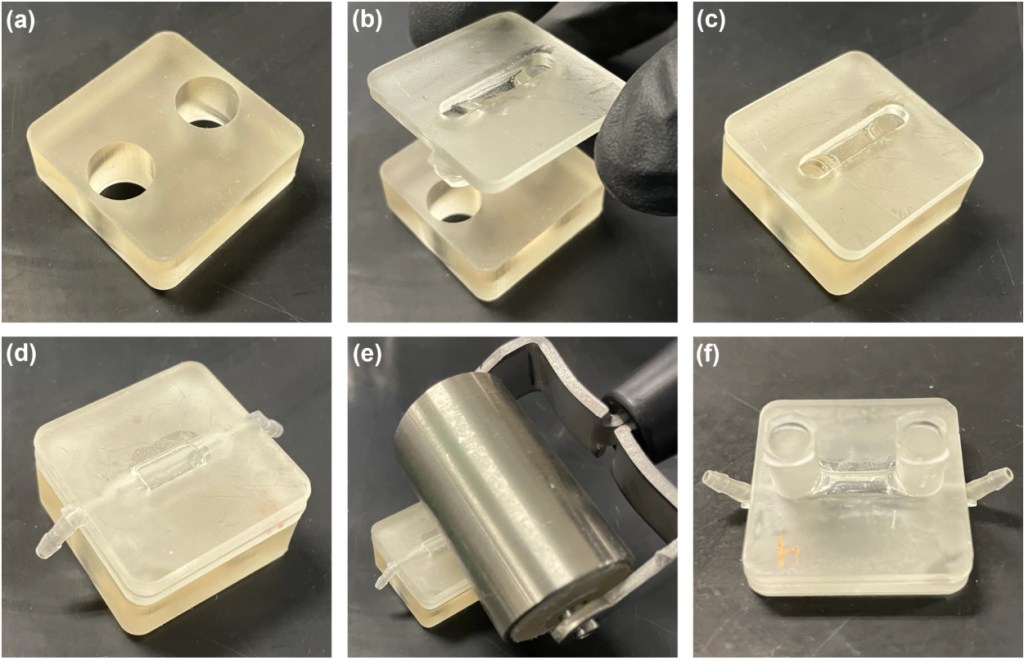

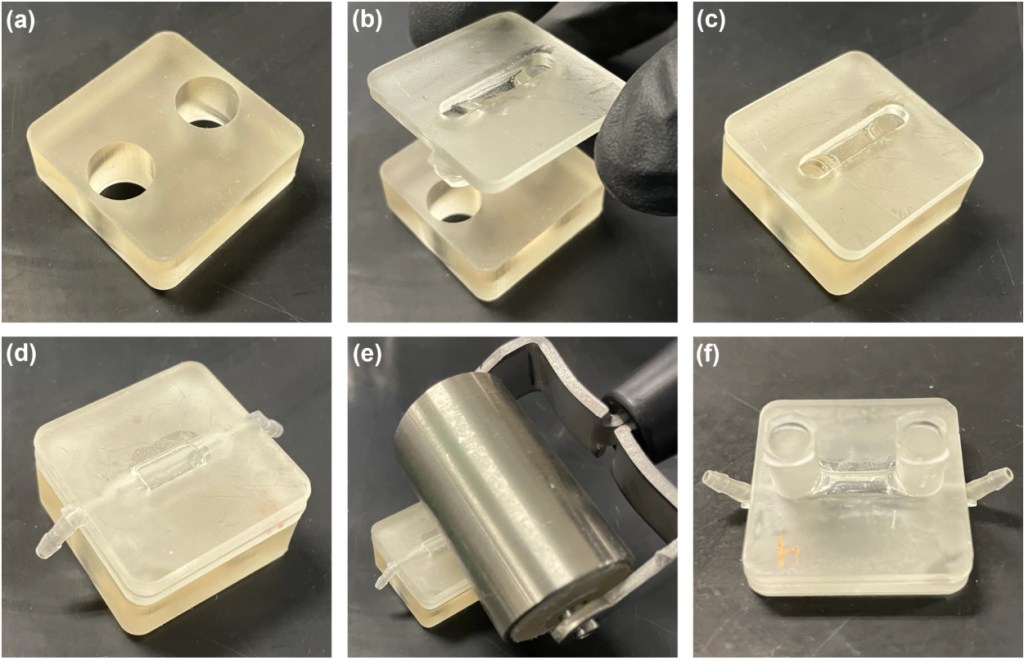

Printed in Nature, the 3D-PBR is made utilizing Formlabs 3B Low Pressure Stereolithography (SLA) 3D printer, counting on a biocompatible resin composed of methacrylate monomer and urethane dimethacrylate. After printing, the researchers fastidiously cleaned the elements with isopropyl alcohol and cured them below UV mild at 60°C for half-hour, a course of that not solely ensures structural stability but in addition enhances readability for imaging.

Twin-compartment setup helps cell interplay

What units this system aside is its design, that includes two compartments separated by a porous polyethylene terephthalate (PET) membrane with a pore measurement of 0.4 µm. This membrane permits media transport and mobile interplay between the compartments with out compromising their separation.

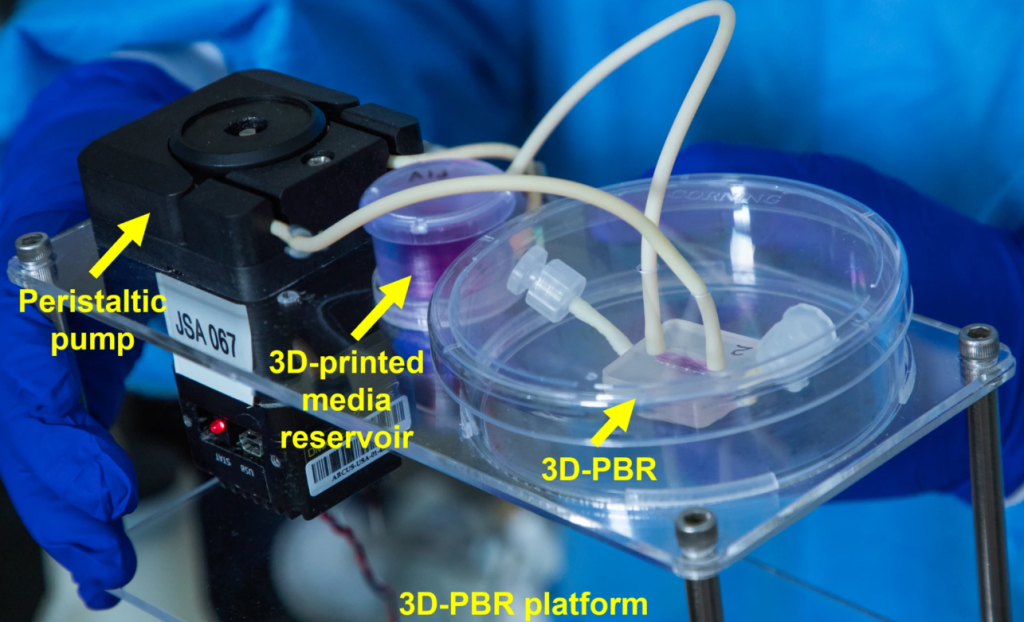

One compartment, designed for vascular cells, consists of Luer-lock ports for managed fluid circulate and has an oblong channel measuring 11.8 mm × 4.8 mm × 0.8 mm. The opposite compartment, meant for MSCs, has an oval-shaped channel measuring 15.8 mm × 4.8 mm × 0.8 mm. Regardless of its intricate design, the whole system, together with the peristaltic pump and 3D printed media reservoir, matches inside a compact quantity of 60 cubic inches.

Researchers selected this resin-based polymer over the generally used polydimethylsiloxane (PDMS), which regularly struggles with points like molecular absorption and manufacturing constraints. The brand new method gives better flexibility and sturdiness, permitting for extra complicated buildings which might be higher suited to varied experimental situations.

Throughout their experiments, the crew cultured MSCs inside a collagen-fibrin gel, a cloth chosen for its potential to offer structural assist and mimic extracellular matrix situations. They ready the gel with MSC concentrations of three.8 × 10⁴ cells/mL for bone differentiation and a couple of.6 × 10⁵ cells/mL for fats differentiation.

In the meantime, human umbilical vein endothelial cells (HUVECs) have been launched to the vascular compartment at a focus of 1 × 10⁶ cells/mL, forming a confluent monolayer over a interval of 21 days. To additional improve the differentiation course of, researchers utilized circulate charges of 23 µL/min and 100 µL/min, that are identified to advertise bone-generating situations.

The crew then used fluorescent microscopy to judge how nicely the MSCs differentiated inside the 3D-PBR. Imaging markers equivalent to VE-Cadherin, ActinRed™ 555, and NucBlue offered clear visuals of cell buildings and interactions. The outcomes have been encouraging, with MSCs demonstrating excessive viability, 92% for MSCs and 91% for HUVECs.

Extra importantly, the cells cultured inside the 3D-PBR exhibited enhanced differentiation in comparison with static situations, displaying better complexity and maturity in bone cell buildings together with extra constant fats cell differentiation.

To confirm the system’s structural integrity, researchers performed µCT scans, confirming that the compartments have been well-sealed and appropriate for prolonged experiments. This step was essential to making sure the reliability of the system’s design.

Whereas the outcomes are promising, the researchers famous just a few limitations. Their focus was primarily on biocompatibility and differentiation, with out analyzing how alerts from vascular cells would possibly affect MSC development at a molecular stage.

The necessity for various media sorts meant vascular cells have been launched solely after MSCs had begun differentiating, which the crew goals to deal with by growing a standard medium and conducting gene expression evaluation.

Shifting ahead, researchers consider the 3D-PBR’s compact design, compatibility with normal lab gear, and flexibility make it a priceless device for finding out bone formation, fats differentiation, and different tissue engineering purposes requiring practical environments.

Advances in 3D printed bioreactors

3D printing has improved bioreactor growth by permitting researchers to shortly create compact, environment friendly designs that assist higher cell development and interplay.

As an illustration, scientists from Massachusetts Institute of Know-how (MIT) and Indian Institute of Know-how (IIT) Madras developed a 3D printed microfluidic bioreactor for rising human mind tissue utilizing SLA 3D printing and dental resin. Priced at simply $5, the reusable system served as a low-cost various to industrial tradition dishes for drug testing and therapy analysis.

Throughout checks, stem cells cultured within the bioreactor confirmed enhanced proliferation and viability in comparison with these grown in typical dishes. The cells developed right into a neocortex-like construction with no decline in viability over seven days. Researchers plan to boost the system with valves and pumps, aiming for environment friendly, inexpensive drug testing and pathogen interplay research.

Argentinian biotechnology agency Stämm Biotech closed a $17 million Collection A funding spherical to advance its 3D printed bioreactor growth utilizing its proprietary Brick Printing Know-how and Sclereid 3D printer. The know-how aimed to miniaturize conventional bioreactors into desktop-sized models, enhancing productiveness by roughly 70 occasions.

Funds have been meant to assist workforce enlargement to round 200 workers and worldwide development. Led by Varana with participation from a number of buyers, the funding brings Stämm’s whole to $20 million on the time, with pilot-scale commercialization deliberate in 2022.

What 3D printing tendencies must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits the absolutely assembled 3D-PBR system with the modular peristaltic pump and 3D printed cell tradition media reservoir. Picture through LANL.