Colorado-based rocket producer Ursa Main has obtained $32.9 million from U.S flight check firm Stratolaunch.

The multi-year contract will see Ursa Main develop and ship 16 of its hypersonic Hadley H13 engines, following a collection of profitable flight collaborations between the 2 companies.

Be a part of AM protection consultants on July tenth at Additive Manufacturing Benefit: Aerospace, House & Protection. Areas are restricted for this free on-line occasion. Register now.

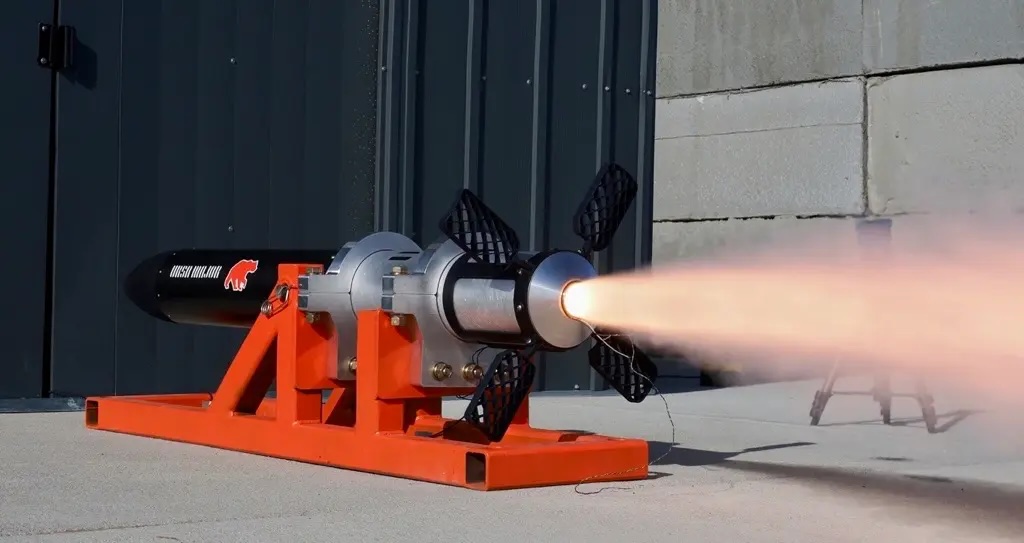

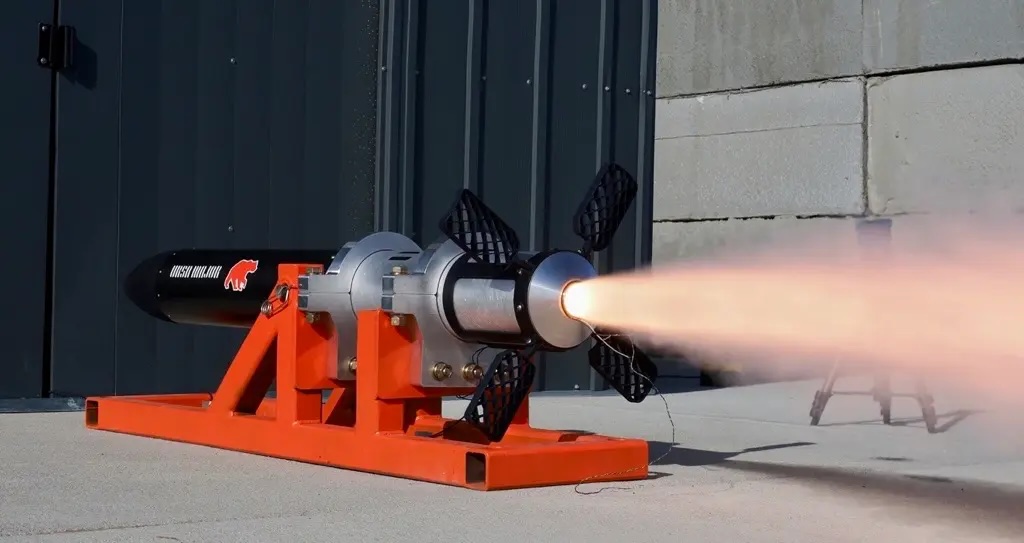

Ursa Main’s Hadley H13, an upgraded liquid rocket engine designed for business, house, and protection purposes, presents elevated engine reusability whereas lowering the price per flight. It has reached sustained Mach 5+ hypersonic speeds in two checks since late 2024, surpassing flight and energy targets aboard Stratolaunch’s Talon-A2 testbed.

“This contract straight helps U.S. hypersonic check infrastructure and the broader crucial to speed up high-speed flight packages that ship for nationwide safety,” commented Dan Jablonsky, CEO of Ursa Main.

“Because the proud companion and hypersonic propulsion supplier to Stratolaunch, we’re centered on getting actual functionality into the sphere – sooner, at scale, and with out compromising efficiency.”

3D printed rocket engines energy Stratolaunch

Ursa Main’s Hadley engine started growth in 2015, with prototypes examined in 2018 and flight qualification attained in March 2022.

The 5,000-pound-thrust (lbf) liquid oxygen and kerosene engine options an oxygen-rich staged combustion cycle optimized for small launch and hypersonic autos. It’s the first product in Ursa Main’s household of propulsion programs, which additionally consists of the Draper, Ripley, and Arroway fashions.

Ursa Main’s engines are greater than 80% 3D printed by mass, utilizing the corporate’s proprietary additive manufacturing expertise. The agency says this strategy reduces manufacturing and supply instances from six months to only one.

The Hadley has already powered profitable flight checks of Stratolaunch’s Talon-A car. Two of those, accomplished as a part of the Pentagon’s Multi-Service Superior Functionality Hypersonic Testbed program (MACH-TB), achieved hypersonic speeds exceeding Mach 5.

Performed in December 2024 and March 2025, the checks reportedly met the Division of Protection’s (DOD) efficiency benchmarks inside a 1% margin. The testbed car additionally achieved profitable restoration post-landing for re-use.

Ursa Main’s Hadley H13 is a mission-upgraded variant designed to mix elevated engine reusability with further begins. This, in flip, drives down prices and helps further check aims and mission profiles for aerospace and protection purchasers.

Ursa Main’s rising order ebook

Ursa Main’s new $32.9M contract provides to its rising order ebook throughout the aerospace and protection sectors.

March 2025 noticed Sirius Applied sciences, the ussubsidiary of Tokyo’s Modern House Provider (ISC), procure ten Hadley launch engines. These are getting used within the growth and testing of the ISC’s ASCA reusable house car, which is anticipated to launch later this yr. The 2 corporations are additionally collaborating to develop a brand new medium-lift engine scaled from Ursa Main’s Arroway mannequin. This challenge will proceed via 2028.

Final yr, the U.S. agency obtained $12.5 million from the U.S. Navy and the Workplace of Strategic Capital to scale manufacturing of 3D printed stable rocket motors (SRM). This funding displays the Pentagon’s rising funding in additive manufacturing, seen as important to bolstering the home missile provide chain. Ursa Main had beforehand agreed to fabricate the Navy’s Mk 104 twin rocket motor, which powers the SM-2, SM-3, and SM-6 missiles.

Elsewhere, in December 2024, Ursa Main and Virginia-based Raytheon Applied sciences carried out two flight checks of a long-range 3D printed SRM for the U.S. Military. On the time, Daniel Jablonsky, Ursa Main’s CEO, revealed that additive manufacturing has enabled “unprecedented timelines,” with almost 300 SRM static check fires accomplished in 2024 alone.

Growing adoption of aerospace 3D printing

Additive manufacturing is enjoying a rising function in engine manufacturing, serving to aerospace companies minimize lead instances and allow extra advanced designs.

Earlier this yr, LEAP 71 accelerated its rocket engine program utilizing additive manufacturing. The Dubai-based engineering firm is scaling the event of its meganewton-class propulsion programs, which embrace 200 kN aerospike and 2000 kN bell-nozzle designs.

Computational engineering and industrial 3D printing are getting used to create advanced propulsion programs tailor-made for future house missions. LEAP 71’s additive manufacturing expertise is able to 3D printing elements over 1.5 meters tall. This facilitates the direct manufacturing of full-scale, high-thrust 3D printed rocket engine parts.

In different information, it was not too long ago revealed that 3D printer OEM 3D Techniques’ Direct Steel Printing (DMP) expertise is getting used to 3D print spacecraft engine cooling programs.

The corporate’s Software Innovation Group (AIG) is working with researchers from Penn State College (PSU), Arizona State College (ASU), and NASA Glenn Analysis Middle to develop thermal administration programs. DMP 3D printing and Oqton’s 3DXpert software program have enabled the workforce to manufacture high-performance radiators and warmth pipes utilizing titanium and nickel-titanium alloys.

Who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to maintain up with the most recent 3D printing information.

You may also comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits Stratolaunch’s Talon-A2 launch and engine ignition for its first hypersonic flight. Picture by way of Stratolaunch.