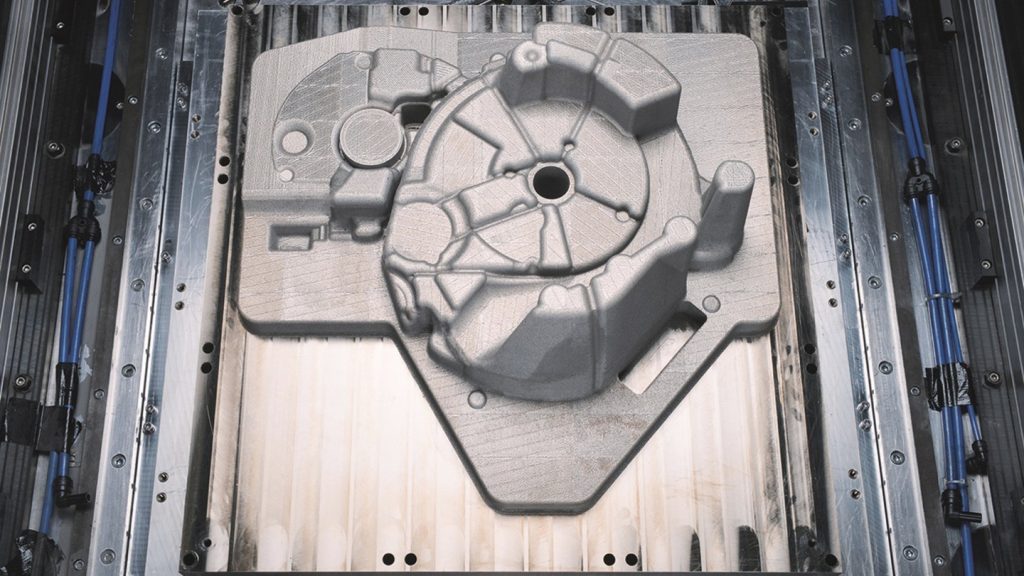

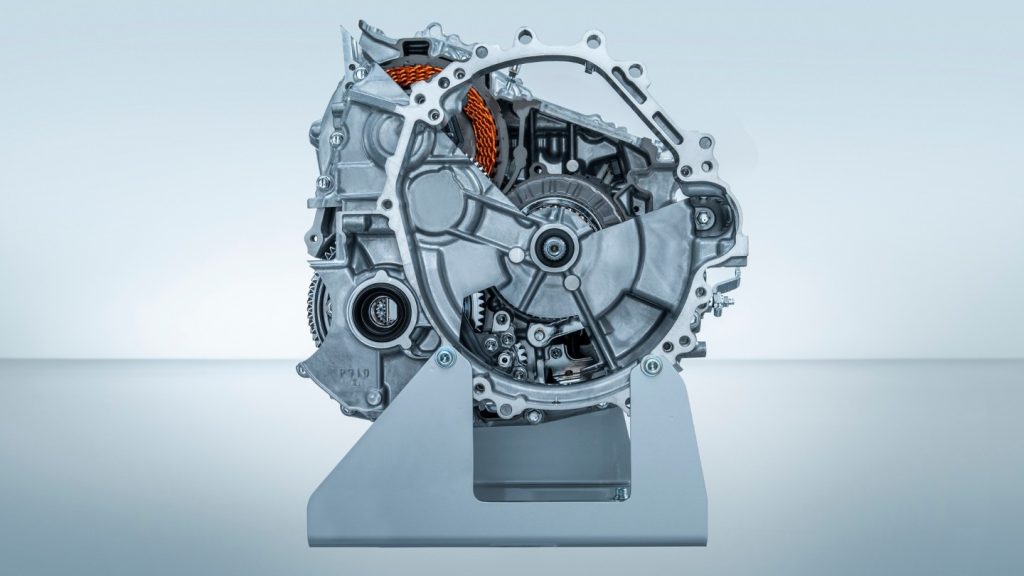

Fraunhofer Institute for Laser Expertise (ILT), a German analysis group specializing in laser-based manufacturing, and MacLean-Fogg, a U.S. provider of engineered steel elements, have produced a big die casting device inlay for Toyota utilizing laser powder mattress fusion (PBF-LB/M). The mission marks the primary profitable demonstration of large-volume instruments with conformal cooling, made potential by a newly developed device metal referred to as L-40. A hybrid mould insert for the Toyota Yaris Hybrid transmission housing was manufactured by combining standard preforms with additively constructed buildings, lowering manufacturing time and enabling extra complicated cooling designs.

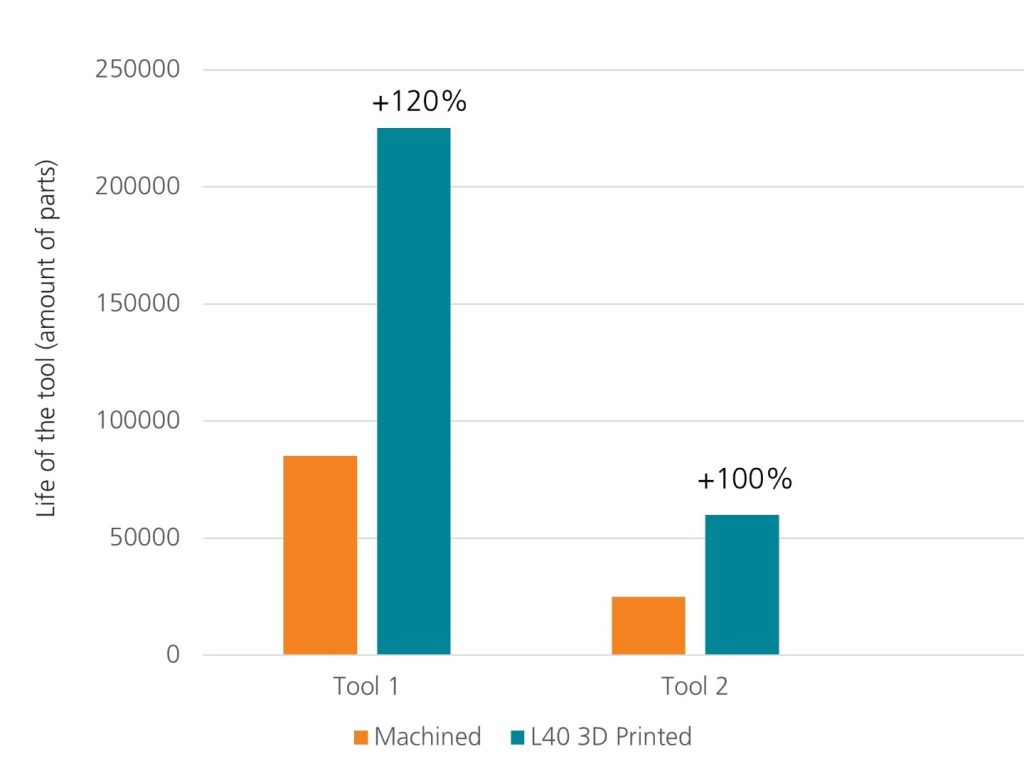

Automotive producers are beneath stress to consolidate elements into fewer however bigger aluminum elements as electrification and price competitors reshape car platforms. This shift locations larger calls for on die casting molds, which should resist excessive thermal and mechanical stresses whereas adapting shortly to design adjustments. Conventional machining and gear steels corresponding to H11, H13, or M300 wrestle to ship these necessities at scale, main Fraunhofer ILT and MacLean-Fogg to concentrate on new machine ideas and supplies. Toyota, already utilizing smaller additively manufactured molds in collection manufacturing, has reported considerably longer device life in comparison with standard inserts, with service lives as much as 4 occasions better.

Niklas Prätzsch, Group Chief for LPBF Course of Expertise at Fraunhofer ILT, defined: “To beat these limitations, we want a brand new era of machines and supplies particularly tailor-made to the necessities of large-format HPDC instruments. It was exactly this mixture that was the topic of the newest adjustments now we have carried out.”

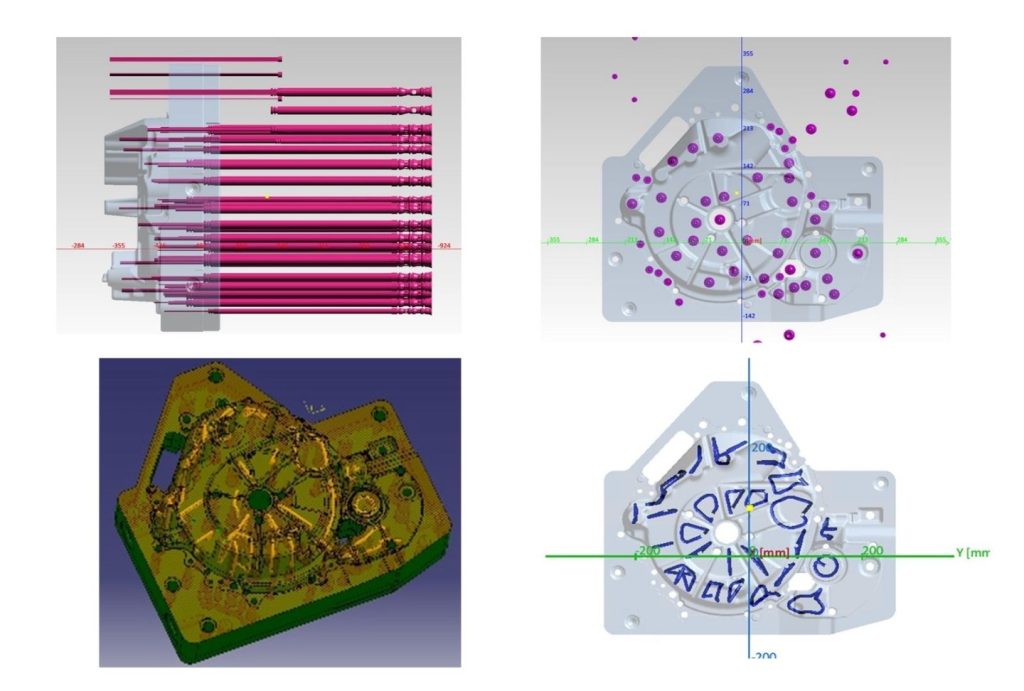

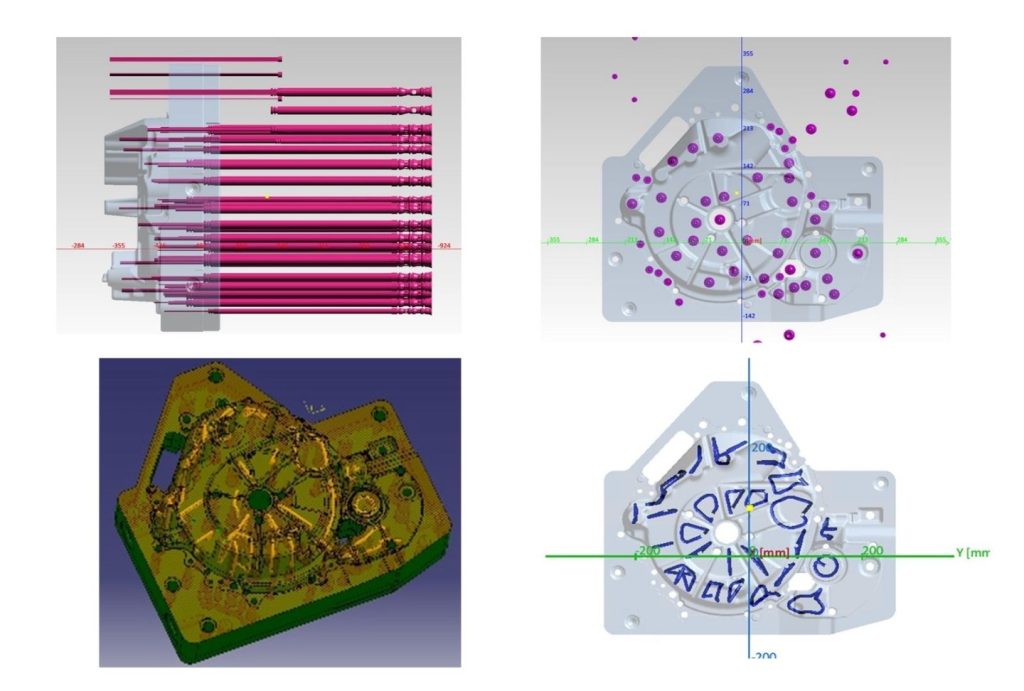

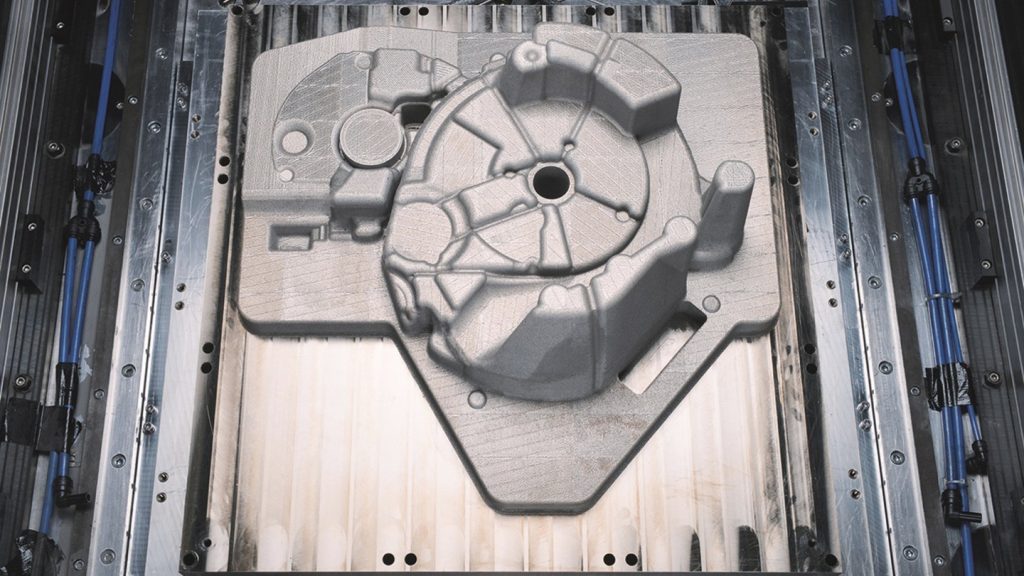

Fraunhofer ILT designed a gantry-based five-laser PBF-LB/M machine with a construct chamber measuring 1,000 × 800 × 350 mm³. In contrast to fixed-bed methods, the machine employs a movable processing head with native shielding gasoline steerage, maintaining parameters corresponding to gasoline movement velocity and laser deflection angle fixed because the construct space scales. This strategy enabled building of inserts exceeding 20,000 cm³, together with the Toyota inlay with a bounding field of 515 × 485 × 206 mm³. A heated substrate reaching 200 °C decreased temperature gradients throughout the construct, decreasing the danger of residual stress and cracking that sometimes happen in massive geometries.

Materials growth was equally vital. MacLean-Fogg created L-40, a metal tailor-made for additive processing of high-pressure die casting instruments. In comparison with established alloys, L-40 confirmed a markedly decrease tendency to crack throughout each printing and warmth therapy. Within the as-built state, the alloy achieved hardness of 48 HRC, tensile energy of 1,420 MPa, and notched affect energy above 60 J. Exams confirmed stability in complicated geometries, together with spherical and overhanging cooling channels, the place standard steels usually fail.

For Toyota’s gearbox housing, the mission workforce adopted a hybrid manufacturing methodology. A preform with vertical cooling channels was first manufactured conventionally, after which conformal channels had been additively constructed on high. This required exact machine calibration to make sure correct alignment and dependable bonding between the 2 sections. After completion, the insert was stress-relief annealed and its useful surfaces had been milled conventionally. Excessive dimensional accuracy within the additive base physique meant solely minimal ending was wanted with out additional materials enter.

Harald Lemke, Director of Product Administration at MacLean-Fogg Part Options, stated: “With L-40, we got down to break the boundaries of additive manufacturing for cold and warm forming instruments generally and die casting instruments particularly. This mission proves that it’s potential to supply massive, complicated and extremely sturdy inserts technically and offers clear milestones to succeed in to be economically enticing. Additive manufacturing is able to tackle actual industrial scale challenges.”

The conformal cooling community throughout the insert was designed to mood thermally confused zones of the mould. By decreasing native temperature peaks, the system reduces thermomechanical put on and extends service life. Earlier research confirmed additive molds lasting as much as 4 occasions longer than standard H13 inserts, and the present mission scaled these benefits to bigger purposes. For producers, this implies fewer device replacements, decrease prices, and sooner response occasions to new design necessities.

Past automotive die casting, the method chain is relevant to different areas requiring sturdy instruments with complicated cooling. Potential extensions embrace plastics processing and composite forming, the place restricted batch sizes and excessive thermal hundreds additionally drive the necessity for extra resilient molds. With giga casting and electrified car platforms elevating tooling calls for additional, scalable additive methods supply a path towards sooner, extra adaptable, and longer-lasting manufacturing instruments.

Restricted areas stay for AMA:Vitality 2025. Register now to hitch the dialog on the way forward for power and additive manufacturing.

Prepared to find who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter and comply with us on LinkedIn to remain up to date with the newest information and insights.

Featured picture exhibits the additively manufactured aluminum die-cast device is a part of the device for the transmission housing of the Toyota Yaris hybrid car. Picture through Toyota Europe.