Researchers from Ocean College of China have developed a scalable methodology for producing lab-grown fish fillets utilizing edible porous microcarriers (EPMs) and bioprinting.

With rising issues over overfishing, local weather change, and meals safety, cultivated seafood has been gaining consideration as a substitute for conventional aquaculture. However scaling up manufacturing whereas maintaining the feel, construction, and dietary profile intact stays a problem.

Now, a examine revealed in Nature Communications particulars how fish muscle and fats cells might be effectively expanded, structured right into a bioink, and 3D printed into fillets that intently mimic wild-caught seafood.

Porous microcarriers allow high-density cell enlargement

As per the crew, this analysis targeted on optimizing gelatin-based EPMs to enhance cell adhesion, development, and differentiation. By introducing sodium chloride (NaCl) throughout cryogenic crosslinking, scientists managed ice crystal formation to fine-tune pore dimension, making a scaffold with the precise porosity for high-density cell tradition.

With this methodology, muscle satellite tv for pc cells (SCs) and adipose-derived stem cells (ASCs) from massive yellow croakers expanded to densities of 6.25 × 105 and 5.77 × 105 cells/mL marking a 499-fold and 461-fold improve, respectively.

To check scalability, the researchers moved from 125-milliliter spinner flasks to a 4-liter bioreactor, the place consecutive enlargement cycles stored cell viability above 80%. The collagenase digestion methodology proved the best for transferring cells onto contemporary microcarriers, sustaining uniform distribution and stopping cell loss.

RNA sequencing confirmed that these expanded cells retained their skill to distinguish, with notable will increase in genes associated to muscle development, extracellular matrix reworking, and cell cycle regulation.

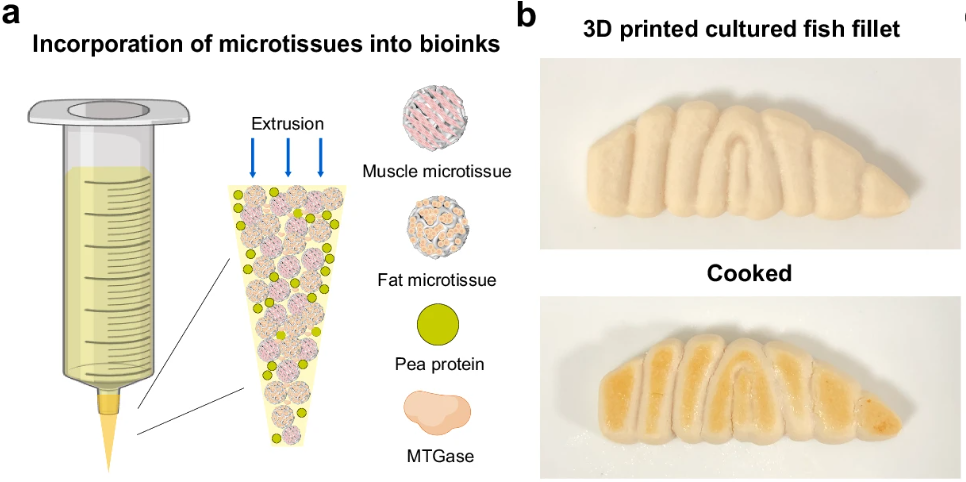

As soon as matured, muscle and fats microtissues have been combined right into a bioink, which was extruded via a industrial 3D bioprinter to create structured fish fillets measuring 100 mm in size and 15 mm in peak. The printed fillets had layered textures much like pure fish muscle and developed a browned floor after cooking because of the Maillard response.

Evaluation confirmed that the printed fish fillets retained moisture (~70%) and had a weight lack of ~35%, much like standard fish. Nonetheless, textural properties like chewiness and cohesiveness have been barely decrease, leaving room for refinement in meals structuring.

Nutritionally, the classy fish had 8.5 grams extra protein per 100 grams than its pure counterpart, with 68.92% much less fats and an 87.93% discount in ldl cholesterol. The omega-3 fatty acid profile remained secure, although sodium content material was larger, exceeding that of pure fish by 192.7 mg/100 g. A 51% improve in important amino acids was additionally noticed, whereas taste compound evaluation highlighted variations in unstable natural profiles, suggesting areas for additional optimization in style and aroma.

Though scaling up stays a problem, researchers estimate {that a} 100-liter bioreactor might yield round 750 grams of cultured fish per batch, signaling industrial potential for EPM-based cell enlargement.

Whereas this examine demonstrates important progress in structured cultivated seafood, fine-tuning fiber alignment, bioink composition, and manufacturing prices might be key to creating lab-grown fish market-ready.

This analysis highlights the feasibility of scalable cultivated fish manufacturing, positioning bioprinting and high-density cell tradition as instruments that would reshape the way forward for seafood. As expertise advances, lab-grown fish might quickly provide a sustainable different to satisfy international demand whereas lowering stress on marine ecosystems.

3D printing fishes on the rise

Efforts to enhance different seafood are increasing, with firms exploring distinctive approaches. Final 12 months, Vienna-based food-tech firm Revo Meals teamed up with Belgian-based Paleo to make its 3D printed vegan salmon much more practical.

Backed by a €2.2M grant from the EU’s Eureka Eurostars program, the two-year mission, which started in August 2024, will see Paleo creating a specifically fermented Myoglobin protein to boost the style, texture, and dietary worth of Revo Meals’ salmon different. Usually present in animal muscle, Myoglobin might be recreated with out animal use so as to add coloration, iron, and aroma. Including to this improvement, Revo Meals claimed its 3D printing course of cuts water use by 90% and CO2 emissions by 75%.

Again in 2020, Legendary Vish, a startup based by a bunch of worldwide college students, was working to deliver 3D printed plant-based fish alternate options to market. The thought stemmed from a 2017 EU-funded analysis mission, the place the crew developed an extrusion-based methodology to create structured salmon fillets utilizing plant-based bio-inks.

Their purpose was to supply a sustainable seafood different amid rising issues over overfishing and environmental harm. As they sought funding to scale manufacturing, additionally they explored regulatory approval and potential partnerships to increase into Scandinavian and European markets.

What 3D printing traits do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals a) Properties of microcarrier-based mobile microtissues bioinks. The diagram was created utilizing BioRender. b) The looks of uncooked and cooked 3D printed cultured fish fillet prototypes. Picture through Ocean College of China.