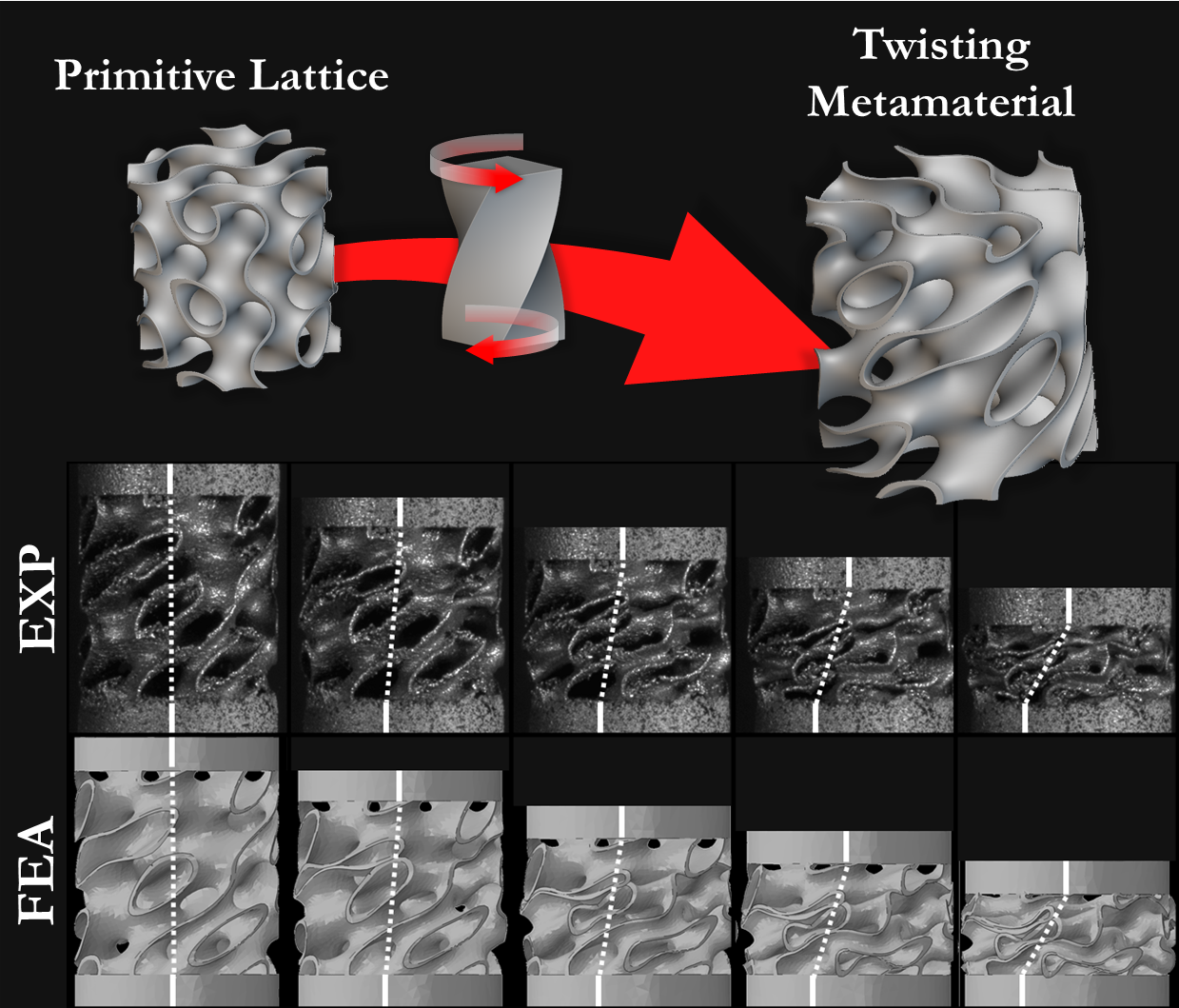

Researchers from universities in Scotland and Italy have developed a brand new 3D-printed metamaterial that may alter its protecting properties based mostly on impression sort and severity. The fabric encompasses a gyroid lattice construction that twists when compressed, providing potential purposes in automotive and aerospace crash safety.

The metamaterial differs from typical safety supplies like foams or crumple zones, which offer mounted resistance ranges. As a substitute, the brand new materials’s response could be mechanically managed by adjusting how a lot it’s allowed to twist throughout compression. This enables it to offer both inflexible safety for extreme impacts or softer cushioning for lighter collisions.

Laboratory exams confirmed the fabric’s adaptability throughout three configurations. When prevented from twisting, it absorbed most power at 15.36 joules per gram. Free twisting lowered power absorption by roughly 10 %, whereas pressured over-twisting decreased it by 33 %. The fabric is manufactured from metal utilizing additive manufacturing processes.

Professor Shanmugam Kumar of the College of Glasgow’s James Watt College of Engineering, who led the analysis, defined the fabric’s benefits. “The protecting supplies utilized in most autos as we speak are static, designed for particular impression eventualities and unable to adapt to various circumstances,” Kumar mentioned. He famous that the fabric requires no complicated electronics or hydraulics to adapt, as an alternative counting on mechanical rotation management.

The analysis, revealed in Superior Supplies, concerned collaboration with Italy’s Polytechnic College of Marche, College of L’Aquila, and Nationwide Institute for Nuclear Physics. The crew used computational fashions and micro-CT reconstructions to account for manufacturing imperfections and predict the fabric’s habits underneath totally different circumstances.

Supply: gla.ac.uk