Resin printing turns into much more approachable when the machine handles the essential steps that usually sluggish customers down or introduce avoidable errors.

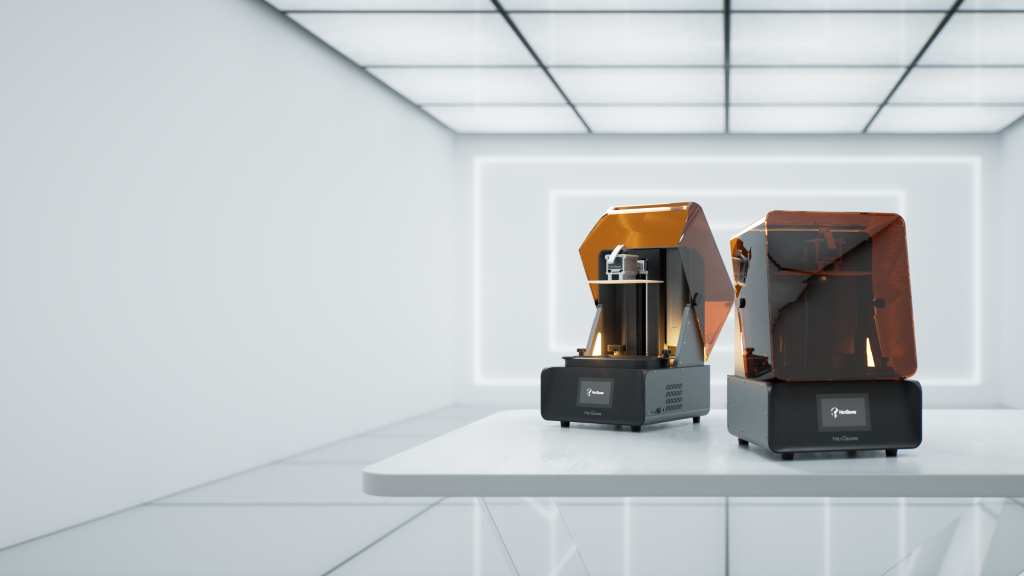

With the novel UltraCraft Reflex RS Turbo, the Chinese language 3D printer producer HeyGears places its consideration on measurable behaviors comparable to mild distinction, repeat positioning accuracy, and actual time movement management. These traits decide whether or not a printer can preserve constant output fairly than delivering occasional standout outcomes.

Since 2015, HeyGears has been working throughout {hardware} growth, software program design, materials engineering, and digital manufacturing methods, and the Reflex sequence displays that mixed expertise by aligning {hardware}, software program, and course of automation right into a single workflow.

Launched earlier this yr, the Reflex RS Turbo is designed “to make precision one thing individuals might depend on with out fixed adjustment,” mentioned a HeyGears spokesperson. “Newbies ought to really feel comfy getting began, and skilled customers ought to really feel assured that the workflow will keep secure throughout lengthy classes.”

Simplifying mannequin preparation and restore

One click on slicing is dealt with by way of preset resin parameters, computerized mannequin restore, and computerized assist era. These helps are formed to be secure throughout printing and straightforward to take away afterward, which helps maintain fashions clear and reduces the quantity of sanding wanted.

Constructed-in technical assist presents direct help from the official group when points happen, giving new customers a quicker path to options in contrast with looking by way of group boards.

Excessive precision efficiency depends upon {hardware} that maintains correct layer alignment all through the whole construct. The C5 grade Z axis holds layer deviation inside 2 µm and maintains clean vertical movement by way of repeated cycles. The Amber Display makes use of an 8K panel with a 566 : 1 distinction ratio produced by a dyed polarizer and a number of optical movie layers that regulate mild transmission.

This construction reduces overexposure and underexposure and preserves advantageous particulars throughout the mannequin. The dyed polarizer is constructed for UV and warmth resistance so the display screen can preserve projection accuracy for greater than 1,000,000 layers.

“We spent loads of time refining the optical stack as a result of small shifts in publicity can add up over lengthy prints,” defined a HeyGears spokesperson. “Stability on the mild supply makes every thing that follows a lot simpler for the person.”

To maintain outcomes constant throughout the whole construct space, the system divides the display screen into 60 calibrated zones that limit mild depth variation to three %. This helps a printing tolerance of as much as 0.05 mm and improves the accuracy of multi half assemblies.

Automation that strengthens print stability

The RS Turbo incorporates full course of automation to maintain the printing sequence secure from begin to end. Auto leveling units exact calibration earlier than every job. Auto refilling and auto heating maintain resin on the appropriate quantity and temperature, with elective heating elevating resin from 10°C to 22°C in 20 minutes. Residue detection makes use of power sensors that reply to 0.1 N and may determine residue as small as 0.2 mm, stopping the print to stop injury.

Printing effectivity improves by way of movement management that adjusts itself primarily based on actual time power knowledge. The system reads this knowledge 80 instances per second and adjusts a seven section movement sequence for every layer. It evaluates cross sections, spacing, and the variety of elements on the plate, then chooses from 18 movement parameters.

Inside testing exhibits that this method reduces printing time 33 % to greater than 50 % compared with single velocity methods whereas preserving print high quality. The body construction is designed to keep up rigidity with flex measured inside 2 µm, and a devoted cooling system can scale back display screen temperature by 10 °C throughout operation. With PAWW20 water washable resin, the Reflex RS Turbo reaches a mean of 4.5 s per layer for lattice fashions.

Put up processing turns into extra manageable when built-in with the broader HeyGears ecosystem. One click on wash and treatment integration shortens ending time, which is particularly helpful for customers producing a number of small fashions or operating steady classes. Steady software program and firmware updates increase compatibility with completely different supplies, workflows, and print optimization options.

By pairing newbie pleasant operation with constant, manufacturing grade accuracy, the Reflex RS Turbo serves the wants of freshmen, hobbyists, studio sellers, and designers alike.

Readers within the UltraCraft Reflex RS Turbo can discover the complete product particulars and buying choices on the official HeyGears retailer. Use the low cost code DPRINTINGINDUST at checkout to obtain $60 off the 3D printer.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential traders, and prospects with the 3D Printing Trade Begin-up of Yr competitors.

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or observe us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits a close-up of a mannequin mid-print contained in the RS Turbo, highlighting assist constructions and construct plate motion. Photograph through HeyGears.