Opdo and Luximprint have introduced a brand new partnership that brings collectively AI-based optical design and additive manufacturing of optical parts. The collaboration permits an end-to-end digital workflow for customized optics, permitting designs to maneuver from natural-language enter to closing manufacturing in considerably shorter timeframes.

Opdo, identified for its AI-powered optics design platform, will combine Luximprint’s Printoptical® manufacturing course of. The businesses goal to streamline the event of superior optics by decreasing the time and complexity historically concerned in each design and fabrication.

From AI-defined intent to 3D printed parts

Opdo’s platform permits engineers to specify optical targets utilizing pure language prompts. AI brokers then generate and simulate manufacturable designs inside minutes. By integrating Luximprint’s direct-from-file manufacturing methodology, the identical designs can now be fabricated with out tooling or guide translation steps.

“Opdo lets engineers describe what they need to obtain with gentle — and AI handles the remaining,” says Stephan Kuehr, Founder and CEO of Opdo. “By including Luximprint’s confirmed manufacturing expertise, we join AI design with digital fabrication in a method that basically adjustments how optical merchandise are developed.”

Increasing entry to customized optics at scale

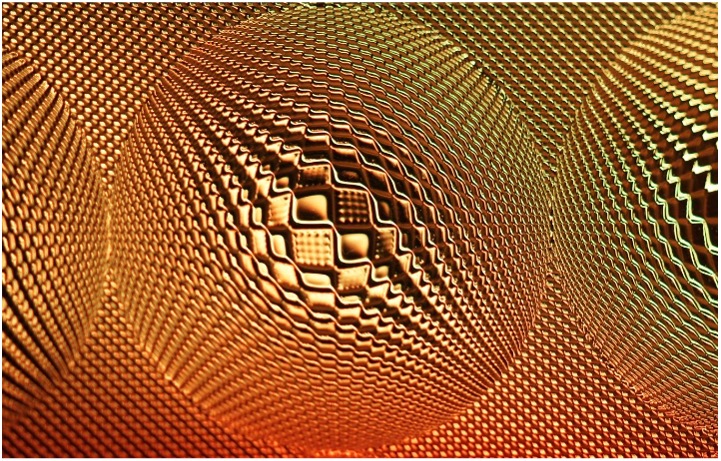

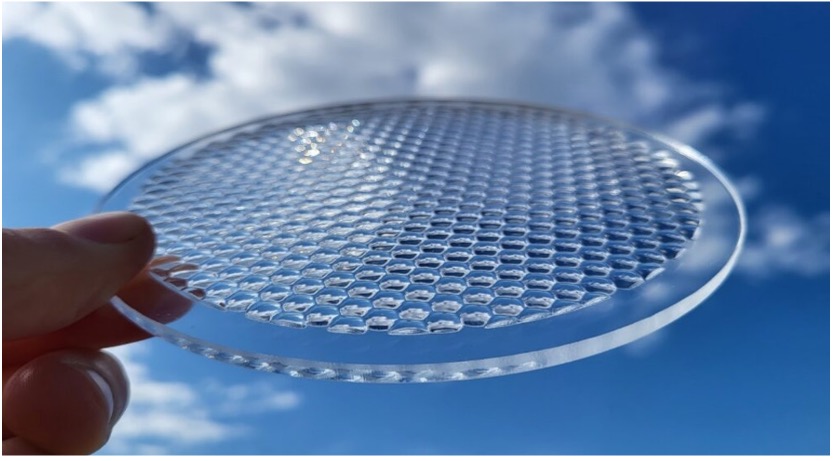

Luximprint’s Printoptical® course of produces optical-grade surfaces immediately from digital design information. It eliminates the necessity for conventional tooling and reduces lead occasions for practical and ornamental optics. When mixed with Opdo’s volumetric design and simulation capabilities, the system affords a sensible resolution for small-batch, iterative, or advanced optical parts.

“We’re excited to carry our Printoptical course of to the Opdo platform,” says Marco de Visser, CEO of Luximprint. “This collaboration connects two complementary improvements — AI design and digital manufacturing — enabling customized optics to maneuver from imaginative and prescient to bodily actuality quicker than ever earlier than.”

A rising digital fabrication community for optics

Luximprint joins a broader group of producing companions built-in into the Opdo platform, which incorporates micro- and volumetric fabrication applied sciences comparable to Xolography and Nanoscribe. The platform is designed to supply engineers a streamlined, data-driven surroundings that covers the complete vary of optical improvement — from freeform lenses and lightweight guides to microstructured surfaces.

With this partnership, Opdo and Luximprint goal to speed up the deployment of customized optics throughout industries that require brief lead occasions, excessive efficiency, and design flexibility.