November 2024 was a transformative month within the 3D printing business, marked by vital product launches, strategic company acquisitions, insightful market analyses, and noteworthy business collaborations. Formnext Frankfurt 2024 served as a central stage for unveiling cutting-edge applied sciences, whereas knowledge from CONTEXT highlighted a stark distinction between the booming entry-level 3D printer phase and a subdued industrial market. This assessment is a rundown of the month’s notable happenings.

Formnext 2024: Defining Improvements in Additive Manufacturing

In November, Formnext attendees have been launched to the CBAM 25 from Unattainable Objects, marking its European business debut after a world unveiling in June. Constructed on Composite-Based mostly Additive Manufacturing (CBAM), the system affords speeds as much as fifteen instances quicker than sure present polymer 3D printing applied sciences. Firm founder Robert Swartz indicated that the CBAM 25 printed a 60-micron layer each 4 seconds, focusing on high-throughput markets like aerospace. CEO Steve Hoover reported robust curiosity from producers searching for to provide high-strength elements with out the warping or shrinkage challenges present in standard strategies.

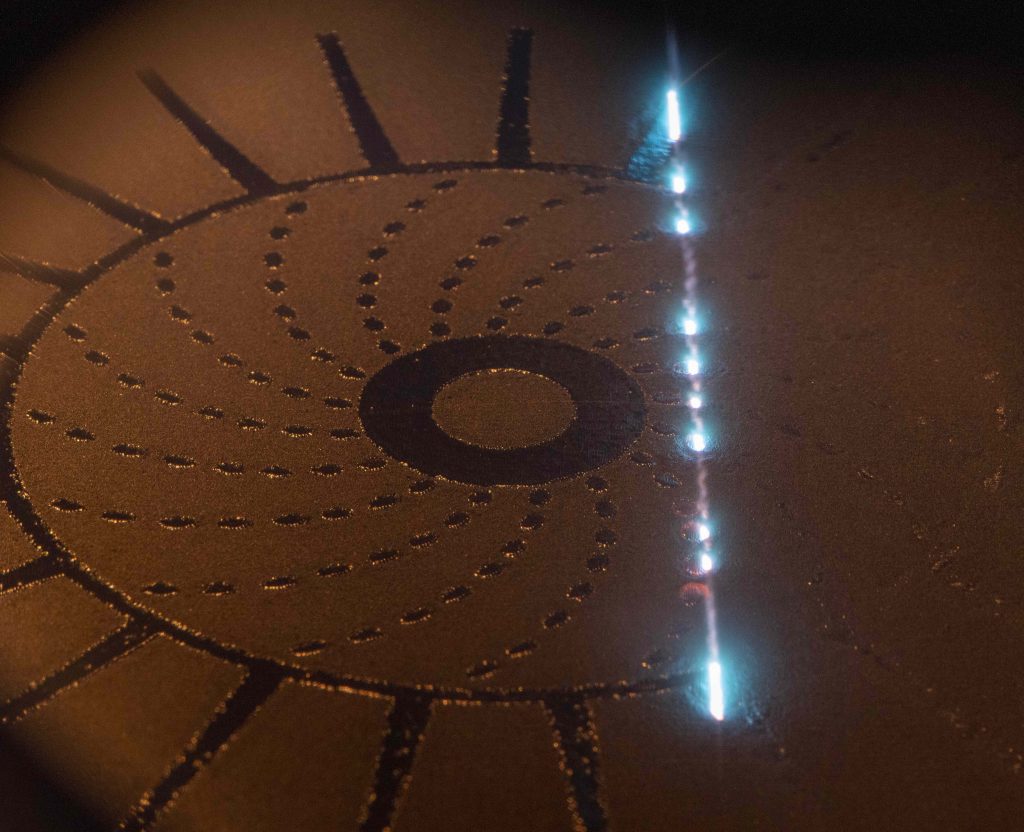

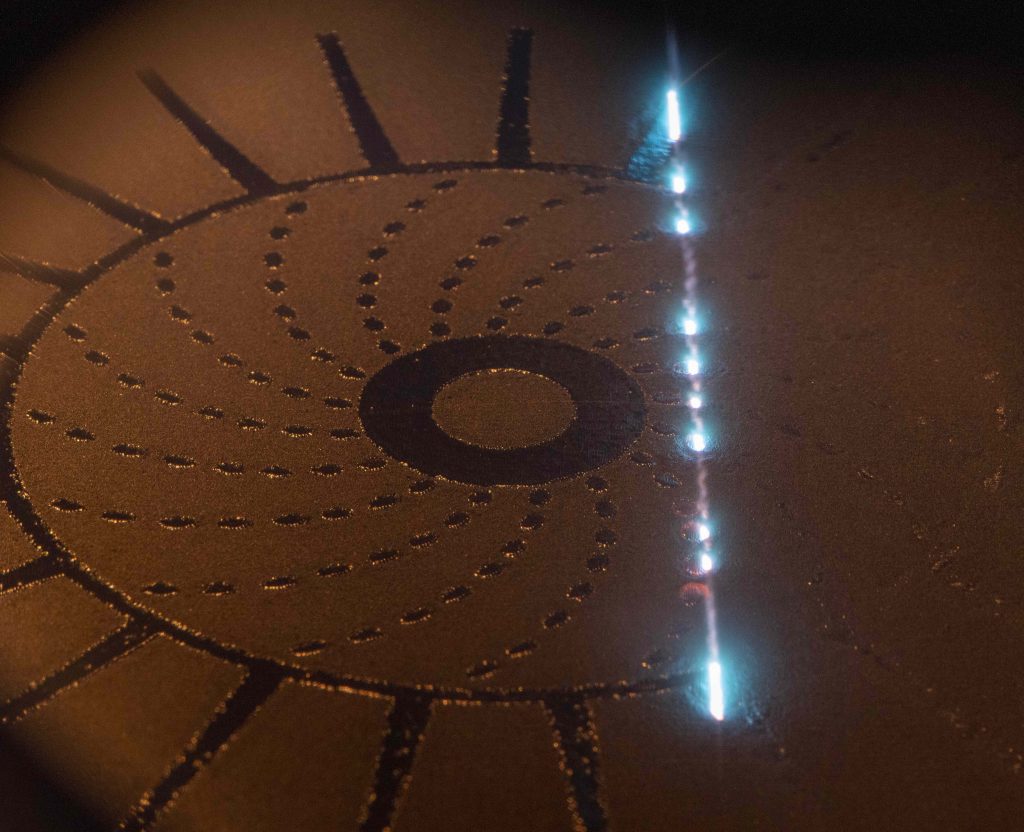

November additionally noticed Prusa Analysis launch the CORE One, a totally enclosed CoreXY 3D printer that includes lively chamber temperature management of as much as 55 °C. Designed to deal with supplies similar to PLA and PETG behind a closed enclosure, the system built-in a 250×220×270 mm construct quantity with an exoskeleton design for elevated rigidity. Josef Prusa emphasised the CORE One’s all-in-one versatility, which aimed to scale back the necessity for a number of specialised machines. Prusa Analysis deliberate to start delivery in January 2025, with a conversion equipment for MK4S homeowners following in March 2025.

At Formnext, nLight unveiled the Corona AFX-2000 beam-shaping laser meant to considerably improve laser powder mattress fusion (LPBF) 3D printing. Based on nLight, one aerospace and protection consumer had already used the AFX-2000 to 3D print aluminum parts at thrice the pace of typical large-format 3D printers. The laser’s dynamic beam-shaping expertise allowed for ring-shaped profiles, which reportedly enabled excessive construct charges whereas sustaining precision within the soften pool.

Guests exploring high-performance supplies encountered Fiberthree’s F3 PA ESD filament. Developed by greater than thirty formulations, it boasted a floor resistance of 10⁵–10⁷ Ω/cm—assembly DIN EN 61340-5 necessities—whereas delivering an 84 MPa tensile energy. The filament’s electrostatic discharge capabilities have been anticipated to serve industries needing each conductivity and mechanical sturdiness.

Formlabs launched its Creator Collection, a safer, extra inexpensive resin line for hobbyist LCD and DLP 3D printers. Priced at $45/kg, these resins averted ACMO, a chemical usually linked to dangerous odors in finances photopolymer supplies. The preliminary choices, Robust Resin and Tremendous Clear Resin, have been validated for machines from Elegoo, Anycubic, and different desktop manufacturers. This launch sought to present cost-conscious customers higher materials high quality with out incurring well being or security trade-offs.

One other spotlight at Formnext was Renishaw’s up to date RenAM 500 collection metallic AM system, augmented by TEMPUS expertise. By permitting a number of lasers to function concurrently throughout your complete powder mattress, construct instances may drop by as much as 50%. Renishaw aimed these enhancements at producers in aerospace and automotive searching for increased throughput with out sacrificing half integrity.

Wayland Additive featured its NeuBeam course of through the Calibur3 machine. Working with a stabilized electron beam, NeuBeam minimized residual stress by a “hot-part” strategy, simplifying powder elimination. Wayland’s Head of New Applied sciences, Martyn Hussey, introduced developments in pace, stability, and powder morphology, emphasizing how these enhancements may benefit industrial clients requiring constant metallurgical properties.

Lastly, Sheffield-based Fyous demonstrated its PolyMorphic 28K, a mold-making system utilizing 28,000 adjustable pins that shaped customized molds in about 20 minutes. The corporate claimed this method was as much as fourteen instances quicker than utilizing standard 3D printing to manufacture molds, decreasing each value and storage overhead for functions similar to vacuum forming, composite layup, or polyurethane molding.

Strategic Developments and Market Dynamics

Amid the flurry of Formnext information, Siemens introduced the deliberate acquisition of Altair Engineering Inc. for roughly $10 billion in November 2024. CEO Roland Busch acknowledged that the merger goals to combine Altair’s superior simulation and AI-driven computational instruments with Siemens’ Xcelerator platform, creating the “world’s most full AI-powered design and simulation portfolio.” Founder James Scapa highlighted the complementary strengths of each firms, emphasizing the enhancement of digital twin applied sciences and AI-based optimization for protection and industrial functions. Siemens projected an 8% improve in its digital enterprise income, including round €600 million to the €7.3 billion reported in FY 2023, and anticipated value synergies of $150 million in EBITDA inside two years post-acquisition. The deal is predicted to shut within the second half of 2025, topic to customary situations.

On the supplies entrance, KIMYA, the additive manufacturing supplies subsidiary of the ARMOR GROUP, ceased filament manufacturing and withdrew from the 3D printing market in November 2024. Hubert de Boisredon, Chairman and CEO of ARMOR GROUP, introduced the closure, citing weaker-than-expected market development and the financial disaster, which led to declining gross sales of latest machines. KIMYA had invested round €15 million since its 2017 launch and provided high-performance filaments to firms like Stratasys, Ultimaker, and AON3D. The exit affected 15 staff, who would obtain assist to transition to new alternatives; The choice adopted comparable strategic withdrawals by firms similar to BASF.

November’s market knowledge from CONTEXT revealed an explosive 65% year-over-year development in shipments of entry-level 3D printers for Q2 2024, now accounting for 48% of worldwide 3D printer revenues. This surge was predominantly pushed by Chinese language producers, with Creality, Bambu Lab, AnyCubic, and Elegoo collectively representing 94% of all sub-$2,500 3D printer shipments. Bambu Lab achieved an unprecedented 336% cargo development, securing 26% of the worldwide entry-level market share, whereas Creality maintained the most important share at 47%. In distinction, the economic 3D printer phase skilled a 25% year-over-year decline, marking the fourth consecutive quarter of lowered shipments. CONTEXT attributed this stagnation to excessive rates of interest and delayed capital expenditures, which hampered investments in large-scale additive manufacturing techniques. Chris Connery, VP of International Evaluation at CONTEXT, famous that affordability and superior options fueled consumer-level adoption, whereas industrial segments awaited extra favorable financial situations for a rebound in 2025.

Recognizing Management and Collaboration

In November, Joe Allison, Principal of 3D Ventures and CEO of Mild Big Studios, was awarded the AMUG Innovators Award in November 2024, recognizing his 34-year profession in additive manufacturing. Allison’s contributions embody main vital developments in stereolithography and selective laser sintering by his roles at Strong Ideas and Stratasys Direct Manufacturing. Beneath his management, Strong Ideas turned the primary third-party provider to Boeing for flight-certified SLS elements and promoted Direct Metallic Laser Sintering (DMLS) for prototyping and manufacturing. AMUG President Shannon VanDeren praised Allison’s affect on the business, whereas Bruce LeMaster, AMUG’s Director at Massive, highlighted Allison’s mentorship and pioneering efforts in creating automated assist era software program.

In the meantime, SME and America Makes introduced their strategic partnership to co-locate the Spring Technical Assessment and Change (TRX) with RAPID + TCT 2025 in Detroit, scheduled for April 8-10, 2025. This collaboration goals to unite key leaders and stakeholders from aerospace, protection, and client items sectors, fostering deeper connections and accelerating the adoption of next-generation additive manufacturing applied sciences. John Wilczynski, Government Director of America Makes, emphasised the partnership’s position in driving innovation by bringing collectively business specialists, researchers, and practitioners beneath one roof. Steve Prahalis, COO of SME, highlighted the advantages of consolidating these occasions to facilitate the alternate of concepts and publicity to various additive manufacturing functions. This strategic transfer leverages Detroit’s robust manufacturing heritage, aiming to boost the protection sector’s manufacturing capabilities by additive applied sciences.

Conversely, Formnext Chicago 2025 was postponed as a result of scheduling conflicts with RAPID + TCT 2025 and the AMUG Convention, together with ongoing financial and geopolitical uncertainties. Sascha Wenzler, Vice President at Mesago Messe Frankfurt GmbH, defined that the choice aimed to keep away from the conflict of main business occasions, guaranteeing higher alignment with exhibitors’ commitments and market wants.

International Traits and Rising Challenges

November additionally underscored China’s rising position in AM, as advisor Dirk Simon introduced insights on China’s globalization of additive manufacturing on the Mobility Goes Additive Annual Assembly. Simon, with intensive expertise working with Chinese language AM firms like Farsoon Applied sciences, Bambu Lab, and Brilliant Laser Applied sciences (BLT), highlighted China’s vital developments in decreasing AM half prices by improvements similar to multi-laser setups, closed-loop powder dealing with, and user-friendly machine designs. He famous that Chinese language corporations at the moment are coming into large-scale collection manufacturing, with firms like BLT exporting metallic elements to main aerospace corporations like Airbus. Simon emphasised the significance of Western firms forming partnerships with Chinese language AM corporations to leverage their cost-effective manufacturing capabilities whereas navigating cultural and technical challenges. He really helpful sturdy buying processes, together with benchmarking, acceptance checks, and complete contract clauses, to mitigate dangers related to provide chain interruptions and mental property considerations.

Prepared to find who received the 2024 3D Printing Business Awards?

What is going to the way forward for 3D printing appear like?

Which latest tendencies are driving the 3D printing business, as highlighted by specialists?

Subscribe to the 3D Printing Business e-newsletter to remain up to date with the newest information and insights.Keep linked with the newest in 3D printing by following us on Twitter and Fb, and don’t neglect to subscribe to the 3D Printing Business YouTube channel for extra unique content material.

Featured picture exhibits the brand new Prusa Core One. Picture through Prusa Analysis.