Researchers from the Institute of Area Know-how (IST) in Islamabad, in collaboration with the Nationwide College of Science and Know-how (NUST) and Ajman College within the United Arab Emirates, have developed a brand new manufacturing setup for steady fiber-reinforced polymer (CFRP) composite filament optimized for fused deposition modeling (FDM) 3D printing. The system permits exact integration of steady E-glass fibers inside a polylactic acid (PLA) matrix, sustaining fiber alignment and polymer encapsulation all through the extrusion course of. Mechanical testing confirmed the continual glass fiber-reinforced PLA filament achieved a median tensile power of 146.75 MPa and a Younger’s modulus of 4.96 GPa, in contrast with 60 MPa and three.68 GPa for neat PLA. The filament’s efficiency intently matched theoretical predictions, confirming its suitability for high-strength additive manufacturing purposes.

The analysis addresses a persistent problem in additive manufacturing: the restricted mechanical properties of ordinary FDM thermoplastics. Though PLA affords ease of processing and dimensional stability, its comparatively low power restricts its use in structural parts. Steady fiber reinforcement can considerably improve the strength-to-weight ratio of printed components, however producing constant, fiber-integrated filaments has been hindered by points comparable to fiber breakage, misalignment, and weak matrix adhesion.

Growing a Dependable Composite Filament Course of

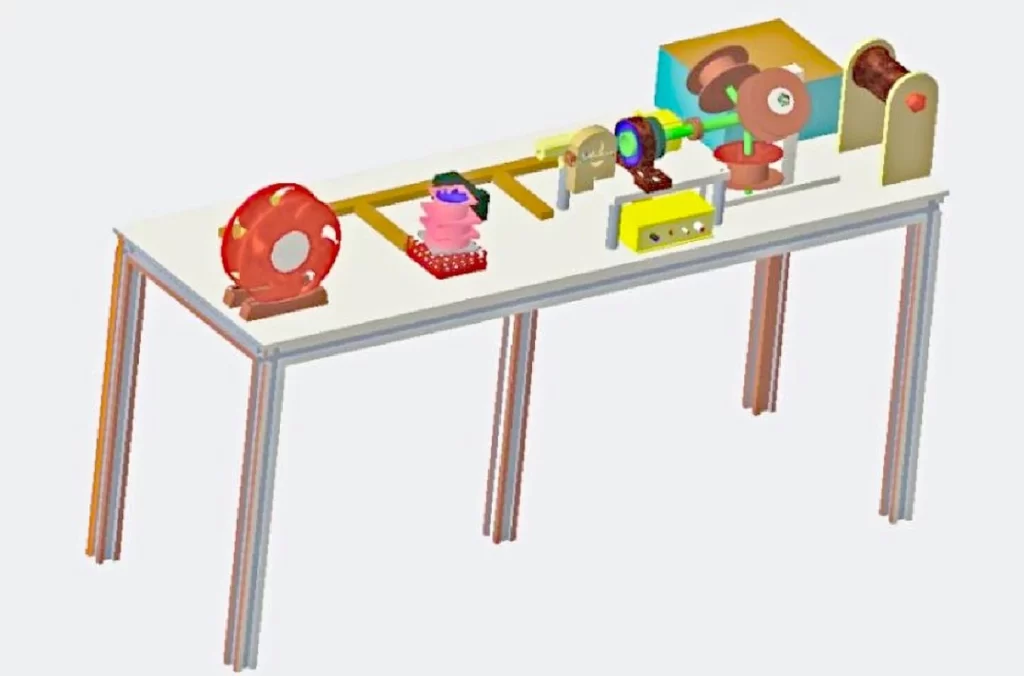

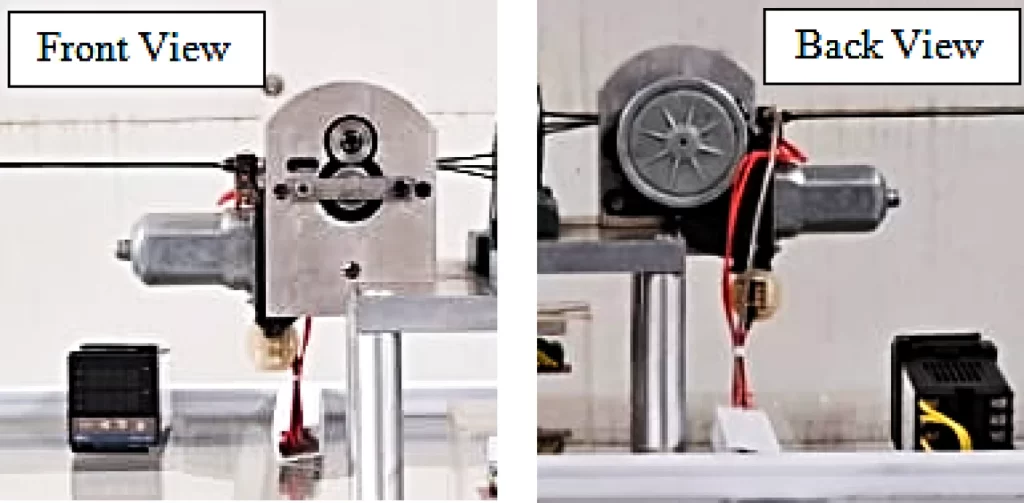

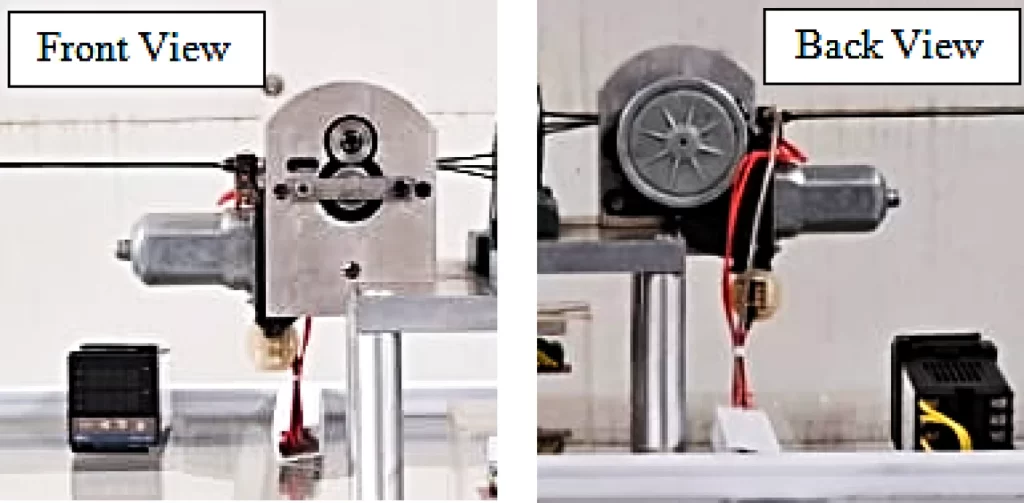

To resolve these limitations, the IST-led group designed and fabricated a gear-driven manufacturing system consisting of 4 built-in subsystems—a winding unit, extrusion meeting, heating chamber, and pulling spool. The system synchronizes feed and extrusion speeds, guaranteeing uniform polymer winding on the fiber and constant filament diameter. Optimized processing parameters included a feed motor pace of 30 rpm, extrusion motor pace of 74–75 rpm, heater temperature of 165 °C, and a spool rotation charge of 10 rpm. These values maintained regular materials circulate and minimized thermal degradation. The ensuing steady glass fiber–PLA composite filament measured 1.75 ± 0.05 mm in diameter with a clean, void-free floor end appropriate for direct FDM use with out printer modification.

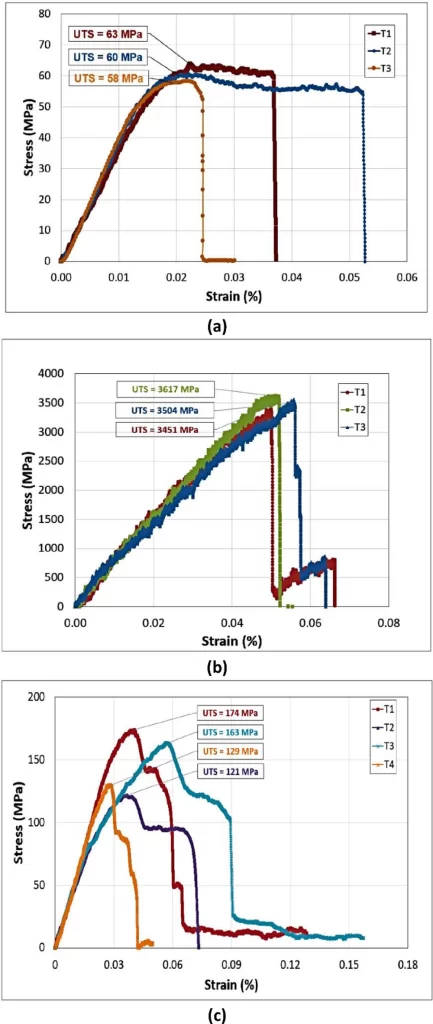

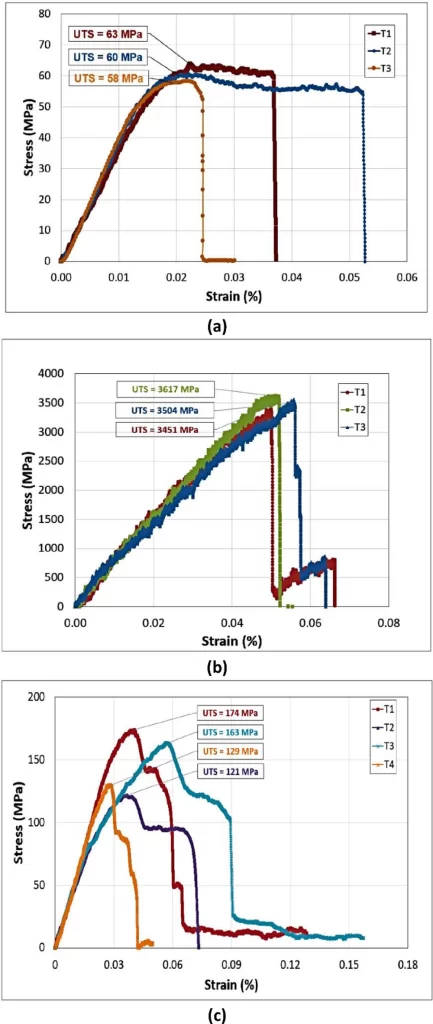

Mechanical characterization was carried out on three materials sorts: neat PLA, steady E-glass fiber, and the composite filament. The glass fiber exhibited the very best stiffness, with a tensile power of roughly 3,508 MPa and a modulus of 74.3 GPa, whereas the composite’s intermediate values confirmed efficient load switch between matrix and reinforcement. The two.4-fold enhance in tensile power and 1.35-fold enhance in stiffness over neat PLA demonstrated that even at a low fiber quantity fraction of two.8%, substantial reinforcement will be achieved.

Mechanical Checks Verify Robust Fiber Bonding

Microscopic and spectroscopic analyses confirmed robust interfacial bonding and uniform impregnation. Scanning electron microscopy revealed full fiber encapsulation by the polymer matrix and minimal void formation. Vitality-dispersive X-ray spectroscopy confirmed a homogeneous carbon–oxygen composition similar to PLA, indicating full polymer distribution across the glass fibers. Thermal analysis utilizing thermogravimetric evaluation discovered negligible mass loss as much as 291 °C, in contrast with neat PLA’s degradation onset close to 212 °C, confirming improved thermal stability. The by-product thermogravimetric curve recognized the PLA matrix’s essential decomposition vary between 291 °C and 437 °C, leaving a 7% char yield primarily composed of glass fibers. Differential scanning calorimetry confirmed a glass transition temperature close to 59 °C and a melting temperature of 152 °C—barely increased than these of neat PLA—indicating restricted polymer mobility and enhanced crystallinity from fiber reinforcement.

The experimental and theoretical Younger’s modulus values, 4.96 GPa and 5.66 GPa respectively, have been in shut settlement, validating the filament’s mechanical effectivity. Researchers famous that small deviations possible resulted from minor fiber misalignment and low fiber quantity fraction, although the filament’s integrity remained constant underneath stress.

Steady fiber reinforcement in additive manufacturing has been studied for greater than a decade, however most experimental or business options have relied on advanced multi-nozzle or co-extrusion methods. Early efforts, together with these by Parandoush et al. and Ismail et al., demonstrated laser-assisted and sintering-based FDM methods utilizing glass and carbon fibers, however confronted challenges with void formation and nozzle synchronization. Later analysis launched ultrasonic-assisted and dual-extrusion methods, comparable to these reported by Zhang et al. and Heidari-Rarani et al., which improved adhesion however added {hardware} complexity. Industrial implementations, just like the Markforged Mark Two 3D printer, have efficiently produced carbon fiber–strengthened parts but rely upon proprietary supplies and managed environments.

PLA stays a most well-liked thermoplastic for composite filament growth because of its biodegradability, low melting level, and secure printability with out requiring heated chambers. E-glass fiber, chosen as reinforcement on this examine, combines excessive tensile power, stiffness, and corrosion resistance with low price and non-conductive habits—avoiding carbon fiber’s drawbacks comparable to nozzle abrasion and electrical conductivity. By using a melt-impregnation-based single-filament course of slightly than dual-channel extrusion, the researchers eradicated fiber breakage and clogging points widespread to earlier strategies, producing a steady, structurally coherent filament appropriate for mechanical purposes.

The custom-designed manufacturing setup demonstrates a sensible and scalable path to manufacturing steady fiber-reinforced composite filaments for 3D printing. The mixture of mechanical power, course of stability, and thermal resistance positions the glass fiber–PLA composite as a promising materials for structural FDM parts. Whereas the examine achieved a modest fiber quantity fraction of two.8%, the outcomes verify that increased fractions may additional improve mechanical properties if course of management is maintained.

Assist form the 2025 3D Printing Trade Awards. Join the 3DPI Professional Committee right this moment.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Featured picture exhibits Stress vs. Pressure Depicting UTS (a) Polymer (b) Fiber (c) Composite. Picture by way of Nature.