Researchers at Penn Engineering have developed a brand new method to enhance the sturdiness of 3D-printed metamaterials by introducing managed irregularities into their construction. The group discovered that by offsetting the connection factors in lattice constructions by roughly 15% from their common positions, they may create supplies which are 2.6 occasions extra proof against cracking in comparison with conventional ordered designs.

“The samples that carried out one of the best, during which it was most troublesome for a crack to develop, didn’t consist of normal repeating patterns,” defined Sage Fulco, the paper’s lead writer. This design method mirrors pure supplies like bone and nacre (mother-of-pearl), which use microscale irregularities to realize larger resilience.

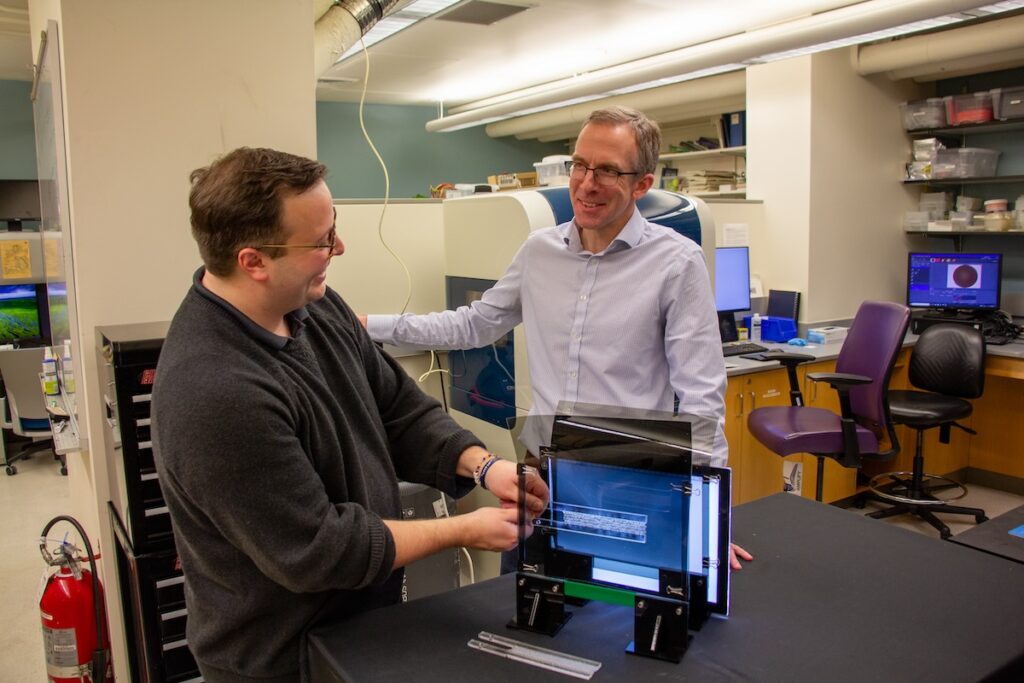

The analysis group examined their idea utilizing laser-cut polymethylmethacrylate (PMMA) specimens and carried out hundreds of computational simulations. Their findings confirmed that whereas the disordered constructions exhibited barely lowered power (≤25%), they maintained comparable stiffness ranges to conventional ordered lattices whereas considerably bettering crack resistance.

Utilizing photoelastic imaging, the researchers noticed that cracks in disordered lattices unfold throughout a wider space as an alternative of following straight paths typical in ordered constructions. This distributed harm sample helps clarify the improved toughness of the irregular designs.

The brand new method affords sensible benefits over conventional toughening strategies, because it depends solely on geometric modifications reasonably than materials additions or specialised coatings. Based on Kevin Turner, Professor at Penn Engineering, whereas disordered techniques current extra complicated design challenges, they are often applied utilizing current manufacturing strategies like 3D printing and laser slicing.

The approach reveals potential for functions throughout varied industries, together with aerospace, medical gadgets, and automotive sectors. Implementation primarily requires modifications to design information reasonably than modifications to manufacturing processes, making it doubtlessly accessible to producers utilizing present gear.

Supply: weblog.seas.upenn.edu