[ad_1]

MIT researchers have developed a brand new 3D printing system known as “Xstrings” that streamlines the manufacturing of cable-driven mechanical gadgets. The system, developed by MIT’s Laptop Science and Synthetic Intelligence Laboratory (CSAIL), combines design software program with specialised printing strategies to create objects that may bend, twist, and fold by embedded cables.

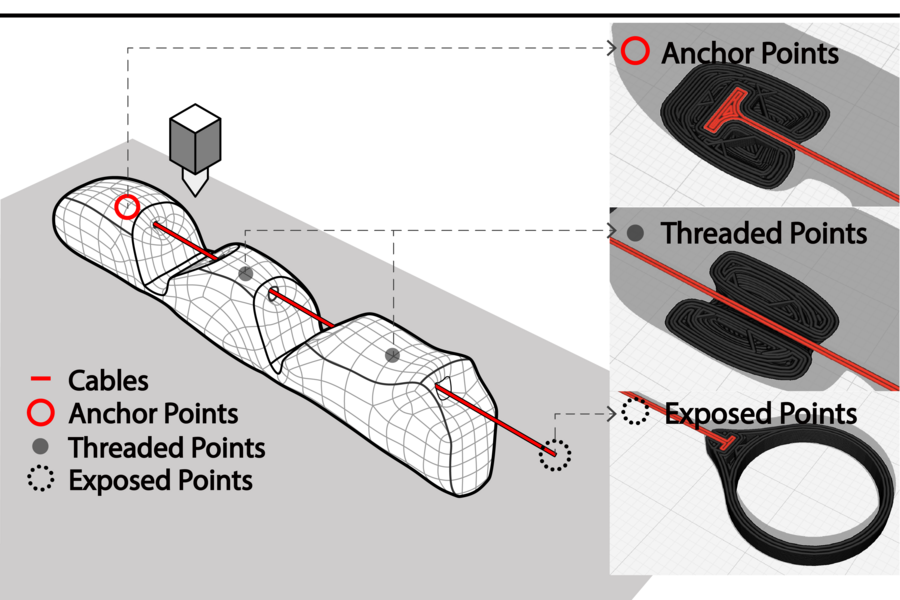

The expertise permits for single-step printing of full mechanisms, together with the cables and joints, utilizing a desktop bi-material 3D printer. In accordance with lead writer Jiaji Li, the strategy reduces whole manufacturing time by 40 % in comparison with handbook meeting strategies. The system operates by printing cables horizontally whereas constructing the construction round them layer by layer.

Testing has demonstrated the sturdiness of the printed elements, with cables withstanding over 60,000 cycles of mechanical motion earlier than failure. The researchers recognized optimum printing situations at 260 levels Celsius with speeds of 10-20 millimeters per second for dependable manufacturing of useful objects.

The group has efficiently produced numerous check objects utilizing the Xstrings system, together with a strolling lizard robotic, a moveable wall sculpture, and a mechanical claw able to gripping objects. The expertise permits customers to customise their designs by software program that controls movement sorts, cable placement, and joint configurations.

The analysis will likely be offered on the 2025 Convention on Human Elements in Computing Techniques (CHI2025). The challenge obtained help from a Zhejiang College postdoctoral analysis fellowship and the MIT-GIST Program. The analysis group contains members from MIT CSAIL, Zhejiang College, and Tsinghua College.

Supply: information.mit.edu

[ad_2]