Additive Industries, a Netherlands-based developer of business metallic 3D printers, has confirmed that Stoke House would be the first manufacturing buyer for its new MetalFab 420K system. The settlement follows a six-month beta program accomplished at Stoke’s facility in Kent, Washington, the place engineers examined one of many first 420K items constructed. Put in in Could 2025, the machine was used to fabricate advanced components for the corporate’s reusable launch automobile.

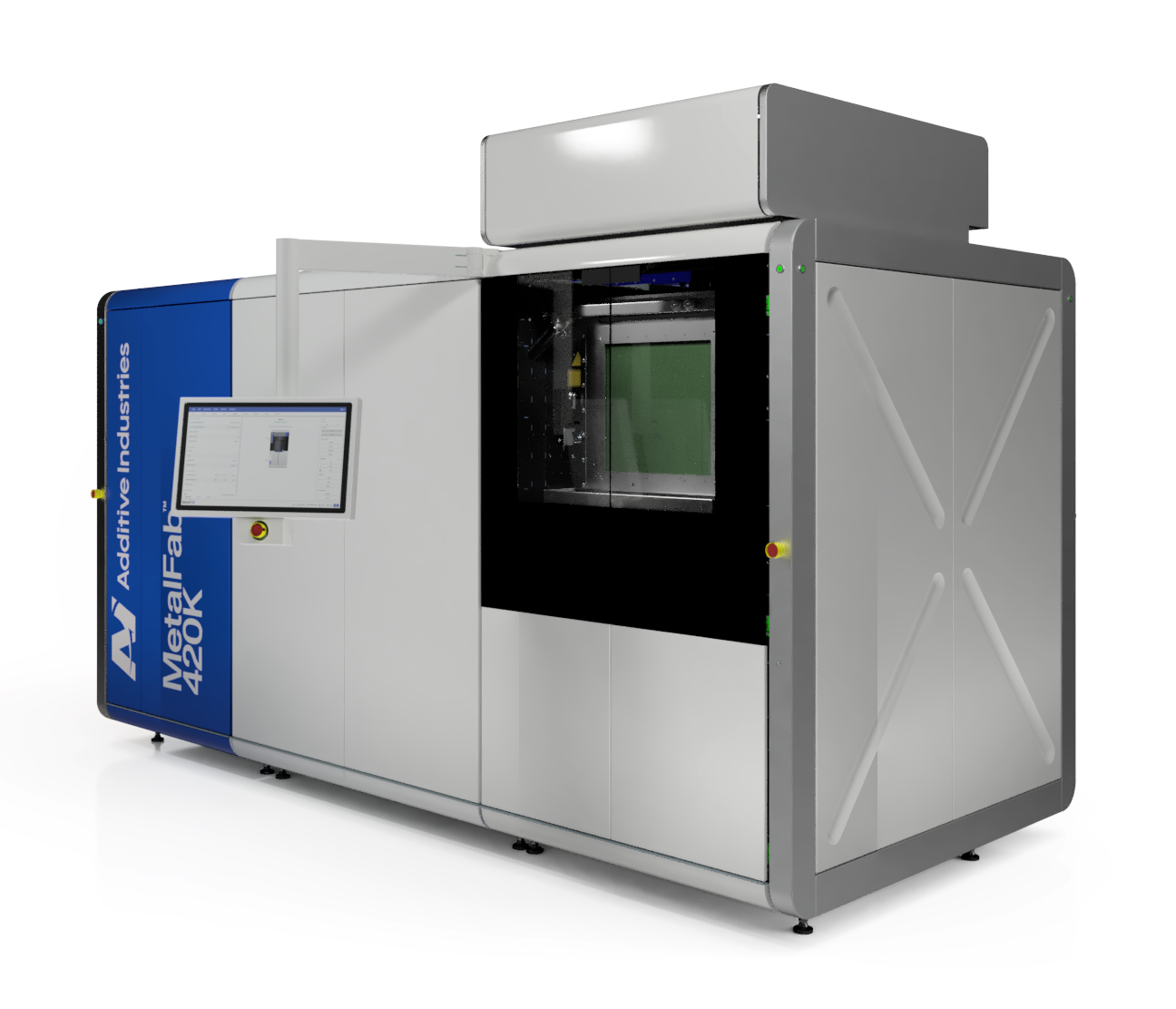

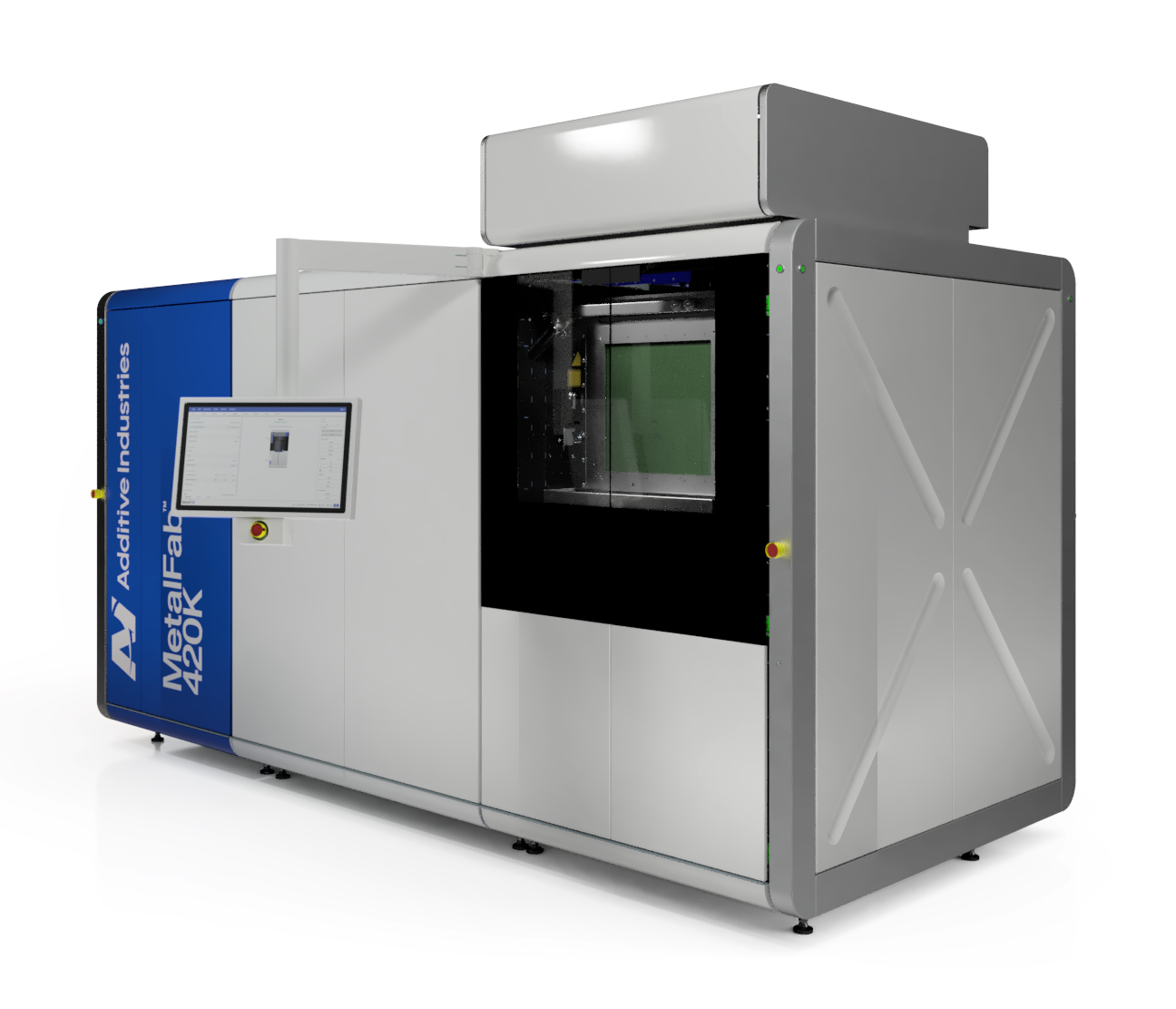

Stoke House, an American aerospace agency creating absolutely and quickly reusable orbital rockets, labored intently with Additive Industries’ improvement group all through the analysis. The MetalFab 420K, geared up with 4 1-kilowatt full-field lasers, follows the sooner MetalFab G2 platform and was engineered for superior additive manufacturing environments that demand precision and consistency.

“Additive manufacturing performs a crucial function in our manufacturing and manufacturing efforts,” stated Kunal Naik, Senior Supervisor of Additive Manufacturing at Stoke House. “The MetalFab 420K provides us the productiveness, precision, and reliability we have to transfer rapidly from design iteration to flight {hardware}. Additive Industries has been a robust companion all through the beta program, and this subsequent step displays our confidence within the system’s readiness for manufacturing.”

After finishing the trial, Stoke House bought 5 MetalFab 420K programs to develop in-house capability. The funding strengthens its additive infrastructure forward of upcoming Nova rocket milestones and positions Additive Industries to scale its newest platform throughout high-demand sectors.

“We’re extraordinarily proud that Stoke House has positioned its continued belief in Additive Industries’ MetalFab expertise,” stated Mark Massey, CEO of Additive Industries. “The system has been designed and developed with precisely any such buyer and software in thoughts, and it’s thrilling to see modern firms like Stoke House undertake our expertise for manufacturing.”

Headquartered in Eindhoven, Additive Industries makes a speciality of large-format, automated metallic 3D printing programs for steady industrial use. Its MetalFab line integrates powder dealing with, modular construct change, and in-process calibration to cut back downtime whereas emphasizing security and sustainability. The MetalFab 420K extends these capabilities with larger laser energy and parallel processing to fulfill the wants of aerospace, power, and high-tech manufacturing.

Stoke House’s Nova rocket program depends on fast design iteration and quick manufacturing cycles. Funded by the U.S. House Pressure, Protection Innovation Unit, NASA, and the Nationwide Science Basis, the corporate is creating a totally reusable launch system supposed to function with aircraft-like frequency. Additive manufacturing permits Stoke House to consolidate assemblies, optimize cooling channels, and speed up testing whereas minimizing materials waste.

With the beta program concluded and a number of 420K items now getting into service, Additive Industries has transitioned the system from improvement to full industrial deployment. Stoke House’s adoption marks the primary operational validation of the four-kilowatt-laser configuration, confirming readiness for broader industrial implementation. Each organizations plan to refine system efficiency via suggestions gathered throughout serial manufacturing.

Assist form the 3D Printing Trade Awards. Make your nominations at this time.

Are you constructing the following large factor in 3D printing? Be part of the 3D Printing Trade Begin-up of the 12 months competitors and develop your attain.

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Featured picture reveals Stoke House’s Nova launch automobile in orbit. Picture by way of Stoke House.