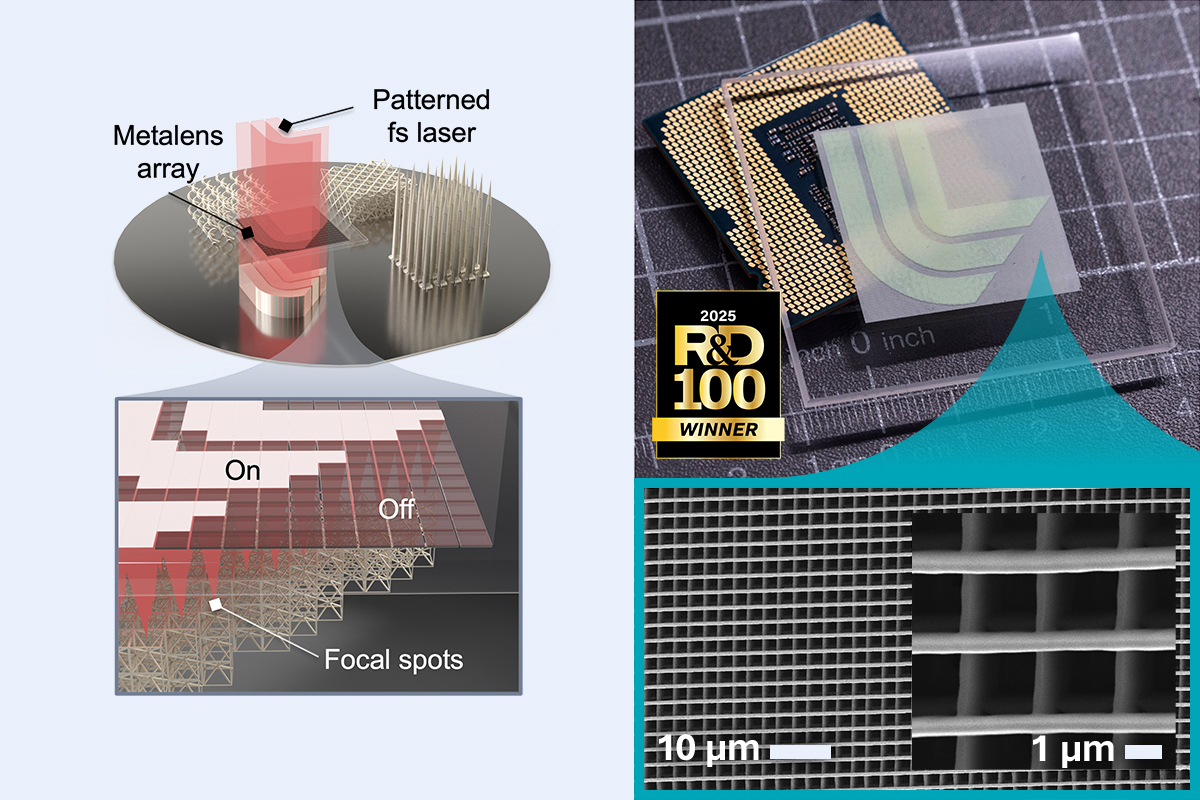

Lawrence Livermore Nationwide Laboratory (LLNL) engineers and Stanford College researchers have developed a brand new strategy to two-photon lithography (TPL) that considerably will increase manufacturing pace whereas sustaining nanoscale precision. The crew’s technique, printed in Nature, makes use of metalens arrays to separate a femtosecond laser into greater than 120,000 coordinated focal spots that function concurrently throughout centimeter-scale areas. The system achieves throughput greater than a thousand occasions quicker than business techniques whereas producing 3D constructions with minimal function sizes of 113 nanometers.

Conventional TPL has been restricted by its reliance on microscope targets, which confined printable areas to some hundred microns. Bigger prints required stitching 1000’s of tiles collectively, creating alignment errors and stopping industrial adoption. The brand new metalens TPL strategy replaces the microscope goal with a tiled array of high-numerical-aperture metalenses, with every lens functioning as a miniature printer.

The crew built-in a spatial mild modulator that adjusts the depth of every focal spot in actual time, permitting the system to modify beams on or off and management linewidths. “Throughout the mission, we realized that by dynamically switching the focal spots on and off and thoroughly planning the printing trajectory, we will really print totally stochastic constructions with a excessive diploma of parallelization,” mentioned Xiaoxing Xia, an LLNL supplies engineer and principal investigator. This adaptive functionality permits the fabrication of non-periodic constructions and sophisticated designs.

The know-how, named MetaLitho3D, has potential purposes in microfluidics, quantum data, microelectronics, photonics, and biomedicine. The platform can fabricate tens of thousands and thousands of micro-particles per day and will scale up LLNL’s analysis on 3D printing fusion gasoline capsules and quantum computing chips. The know-how not too long ago received a 2025 R&D 100 Award, suggesting business viability for industrial purposes.

Supply: llnl.gov