Researchers from John Hopkins College have developed a brand new 3D printing programming language referred to as Time Code (T-Code). Outlined in a Nature Communications research, co-authors Sarah Propst and Jochen Mueller declare T-Code improves 3D printing velocity and high quality for complicated multi-material components.

Optimized for Direct Ink Writing (DIW) additive manufacturing, this new strategy makes use of a Python script to divide conventional G-Code into two separate tracks. One controls the 3D print path, whereas the opposite manages printhead features.

Not like G-Code, which executes duties line-by-line, T-Code makes use of time to synchronize the 3D printer’s movement with key instructions like materials switching and circulation changes. This eliminates frequent start-stop interruptions that gradual manufacturing and create defects, enabling steady, uninterrupted fabrication. Consequently, 3D printing turns into quicker with out dropping accuracy or element, facilitating superior capabilities like easy gradients and in-situ materials modifications.

In response to the Baltimore-based researchers, their new methodology can deal with complicated designs which can be difficult to attain with G-Code. T-Code reportedly gives potential throughout numerous fields, together with biology, electronics, mechanics, and optics. Propst and Mueller imagine it may help the manufacturing of 3D printed wearable electronics and sensible prosthetics. Additionally they emphasize T-Code’s means to speed up simultaneous manufacturing, providing promise for scaling mass customization.

Introducing T-Code: a brand new programming language for 3D printers

G-Code (brief for Geometry Code) is the usual programming language for extrusion-based 3D printing. Initially developed for CNC machines within the Nineteen Fifties, it employs line-by-line execution that requires the 3D printer to decelerate and cease when executing a brand new command. This slows the 3D printing course of and may result in over-extrusion defects that impression accuracy and precision.

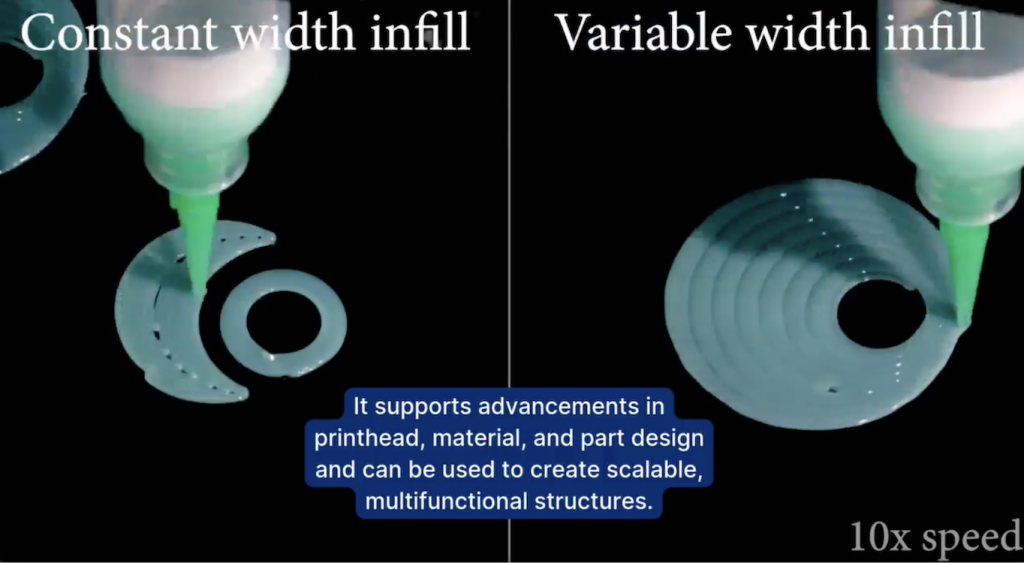

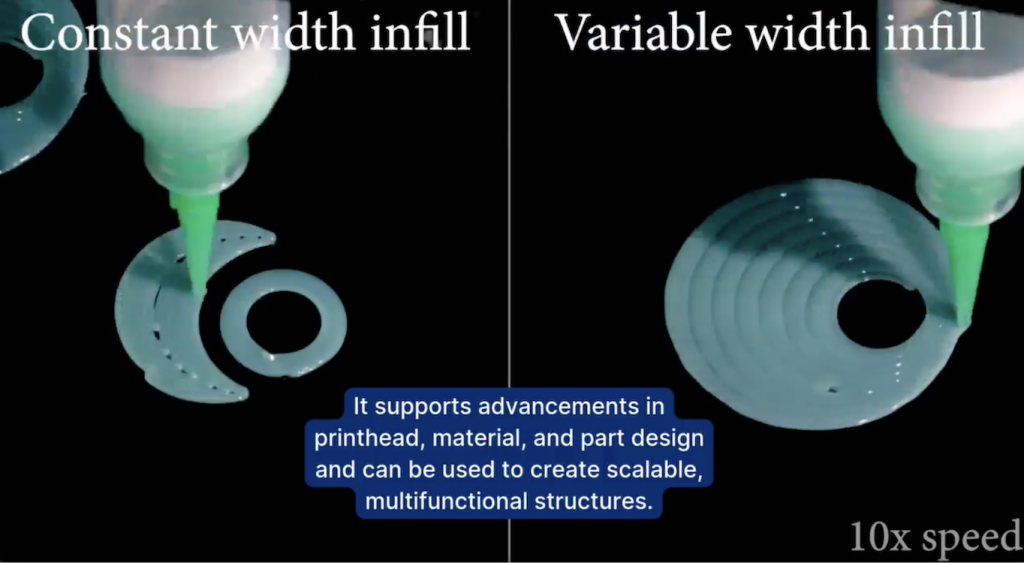

In single-material DIW printing, pauses often occur solely when the print path modifications path. Nevertheless, when including operations like materials switching, extra instructions have to be inserted into the G-code, which disrupts the extrusion course of and will increase the chance of defects. By separating auxiliary controls from motion, T-Code ensures that the printhead features easily with out interrupting the 3D printing course of.

How does T-Code work? First, a daily G-Code file containing the specified areas of auxiliary instructions is imported into Python. The researcher’s script separates the motion and auxiliary instructions into two teams whereas preserving them correctly aligned.

As soon as decoupled, separate motion instructions are merged right into a easy, uninterrupted 3D print path. Subsequent, the Python script calculates the 3D printer’s velocity and velocity to generate a velocity profile. It then determines the precise timings of the auxiliary instructions by mapping their location on the rate profile. These timestamps are formatted into an inventory, prepared for execution. Lastly, a sign from the 3D printer executes the script, synchronizing the printhead operations.

In response to the researchers, this strategy facilitates the creation of objects with superior purposeful gradients. These are troublesome to attain utilizing standard G-Code, which breaks down the print patch into discrete steps. Because of this gradual modifications, resembling various the filament thickness, materials composition, or UV-curing depth, are executed in segmented steps, which may result in defects, lengthy print occasions, and decreased precision.

Utilizing T-Code, nevertheless, unlocks easy, continuous changes that create multi-material gradients with out stoppages. The brand new strategy may also create objects with various densities or materials compositions in particular areas. By exactly controlling the fabric ratios throughout 3D portray, T-Code can produce complicated components with graded mechanical, optical, or compositional properties.

The brand new strategy has been designed for integration into present 3D printers with out altering the {hardware} or software program. As such, its creators declare that T-Code permits low-cost, desktop 3D printers to “produce buildings comparable in high quality to high-end options.” Whereas optimized for DIW, the programming language gives common compatibility with all functions, supplies, and extrusion programs that work with standard G-Code. This consists of FDM expertise, high-viscosity inks, and volumetric extruders. It might probably even be used alongside CNC milling machines and lathes.

Propst and Mueller are assured that their strategy shall be worthwhile for producing scalable, multifunctional parts throughout a variety of functions, together with organic, electrical, optical, and mechanical fields.

Analysis enhances multi-material 3D printing

John Hopkins College just isn’t the one establishment exploring novel methods to optimize multi-material 3D printing. Final 12 months, a workforce from Seoul Nationwide College developed a two-step course of to create components with particular gradient properties in FDM 3D printing.

Usually, customers can’t obtain exact spatial management over materials composition with FDM 3D printers as a result of the nozzles can solely extrude a single filament at a time. The South Korea-based workforce overcame this hurdle by fabricating a “digital materials.” This was created by depositing totally different base supplies layer by layer. Throughout extrusion, these supplies have been homogenously blended within the nozzle, creating purposeful materials gradients within the last half.

The analysis paper, revealed in Nature, offered a novel blended FDM (b-FDM) course of that efficiently creates components with vital property variations. For instance, it will probably mix mechanical energy, electrical conductivity, and shade in ways in which conventional strategies can’t. Importantly, this strategy might be carried out utilizing commonplace FDM 3D printers and filaments, offering a low-cost and accessible means of manufacturing purposeful gradient supplies.

Elsewhere, College of Illinois Urbana-Champaign and the Beckman Institute for Superior Science and Know-how developed a chameleon-inspired methodology for multi-color 3D printing. Whereas most multi-color approaches require a number of supplies, this methodology solely wants a single ink, growing effectivity and sustainability.

The workforce’s UV-assisted-ink-writing strategy permits colours to be altered “on the fly” throughout 3D printing. Altering the energy of the UV-light radiation because it cured an ink made out of photo-cross-linkable bottlebrush block copolymers (BBCP) brought about the polymers to crosslink in several methods. This translated to a broad spectrum of 3D printable colours, demonstrated by the workforce’s multi-color chameleon picture and recreation of Vincent Van Gogh’s “Starry Evening” portray.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You can too comply with us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits Multi-color 3D printing with T-Code. Picture through Johns Hopkins College.