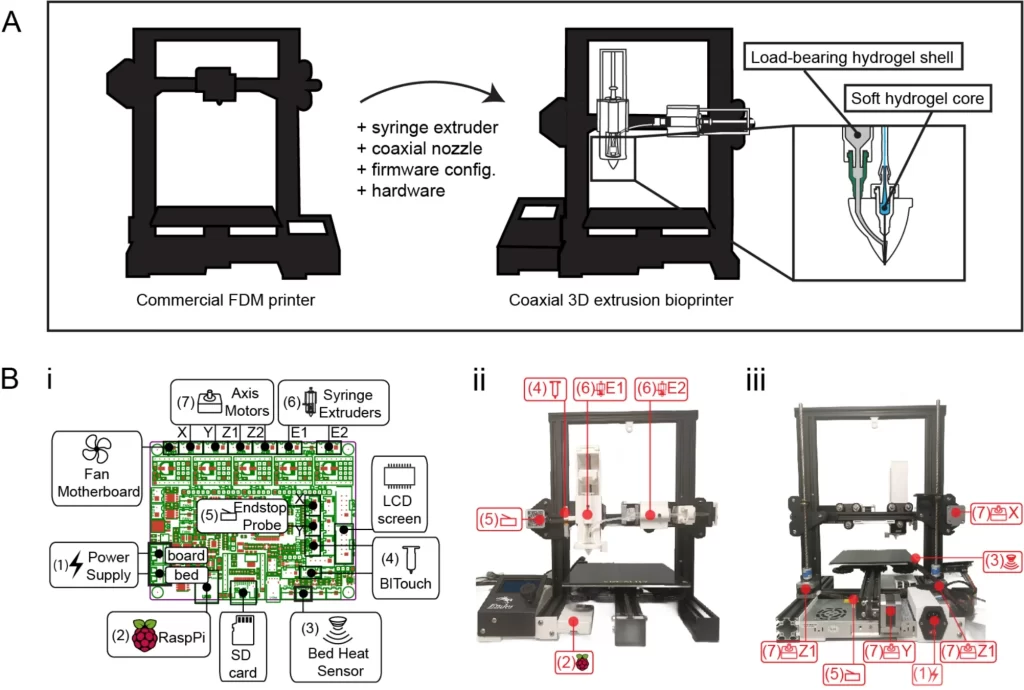

A crew on the Bioengineering Institute of Know-how, Universitat Internacional de Catalunya, has developed a DIY coaxial 3D bioprinter by modifying a Creality Ender 3 Professional desktop 3D printer. The open-source system prices underneath €600 and permits simultaneous extrusion of two hydrogel bioinks by way of a coaxial nozzle. The gadget was validated by printing mesenchymal stem cell (MSC)-laden hydrogels with excessive form constancy and cell viability. Particulars of the challenge had been printed in Nature Communications.

Creality, a Chinese language producer of low-cost FDM printers, produces the Ender 3 Professional, which was tailored by changing its hotend with two stepper motor-driven syringe pump extruders. The 3D printer’s motherboard was upgraded to a 32-bit SKR 2.0 Rev B, enabling unbiased management of each extruders. Firmware was configured utilizing the open-source Marlin platform. A customized coaxial nozzle was fabricated utilizing Liqcreate Clear Impression resin and printed on a Phrozen Sonic Mighty 8K DLP printer. The nozzle featured a 27-gauge internal needle for core materials and a 14-gauge shell inlet, assembled concentrically to help coaxial stream.

Two nozzle configurations had been examined, each with 200 µm internal diameters and outer diameters of 640 µm and 840 µm, respectively. Movement simulations in COMSOL Multiphysics confirmed that the broader nozzle induced higher velocity variations between shell and core, whereas the narrower configuration yielded extra uniform stream. Rheological testing confirmed {that a} thermoresponsive methylcellulose-based shell might crosslink a gelatin-alginate core in situ. Scaffold buildings remained secure when extruding core bioink concentrations as little as 0.5% alginate, with elastic modulus halved in comparison with the 1.5% formulation.

Printing efficiency was evaluated at a pace of three mm/s with stream charges of 0.917 µl/s (slim nozzle) and 1.529 µl/s (extensive nozzle). Scaffold constancy was quantified by evaluating relative top throughout numerous core-shell ratios. Constructions started to break down when core stream exceeded 40% with out calcium crosslinking, however remained intact when CaCl₂ was included within the shell hydrogel. Massive woodpile and vase buildings had been printed utilizing a gradient extrusion operate (M166 command in Marlin), permitting automated variation in core-shell composition over the Z-axis. The printed scaffolds displayed constant geometry, open porosity, and localized materials transitions.

MSCs had been harvested from five-week-old male Sprague-Dawley rats following accepted protocols on the Autonomous College of Barcelona. Cells had been encapsulated within the alginate-gelatin hydrogel core and printed into sq. scaffold buildings utilizing the slim nozzle configuration at a 30–70 core-shell ratio. Dwell-dead staining at 1, 7, and 14 days confirmed excessive cell viability, with printed circumstances exceeding 90% by day 7 and sustaining viability by way of day 14. Outcomes confirmed that the methylcellulose-based shell allowed adequate nutrient diffusion and guarded embedded cells throughout extrusion.

Business coaxial bioprinters usually depend on fastened stainless-steel nozzle designs and lateral feed geometries that restrict compatibility with viscous or particulate-rich bioinks. Against this, the design offered on this examine accommodates high-viscosity supplies and reduces clogging danger when bioinks are co-optimized with nozzle geometry. The shell layer additionally prevents dehydration of the core throughout lengthy print periods. CAD recordsdata, firmware modifications, and a full supplies listing had been printed alongside the examine to help replication and additional growth.

This method expands the accessible toolset for labs exploring complicated scaffold architectures with out entry to high-end bioprinters. Whereas coaxial nozzles inherently scale back decision resulting from their dual-channel format, they provide the power to spatially compartmentalize completely different supplies or cell sorts. The researchers be aware that decision trade-offs are justified in instances requiring mechanical gradient tuning or managed organic compartmentalization. With its low price and versatile structure, the system might help growth of multiaxial or microfluidic printheads, enabling broader functions in tissue engineering analysis.

Need to assist select the 2025 3DPI Awards winners? Be part of the Professional Committee at this time.

Prepared to find who received the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business publication to remain up to date with the most recent information and insights.

Featured picture reveals schematic of 3D extrusion bioprinter and coaxial nozzle meeting. Picture by way of Nature Communications.