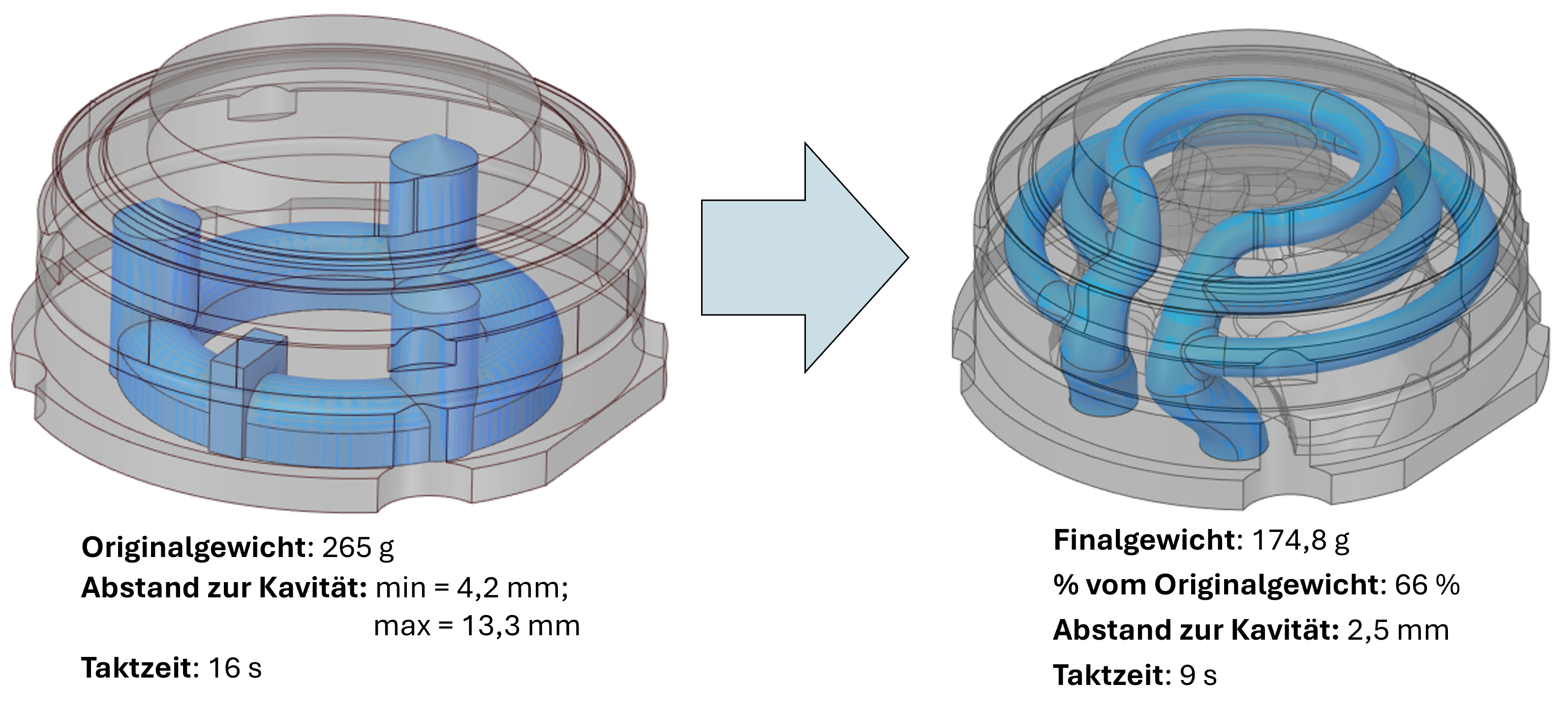

A German analysis mission has demonstrated that 3D printed manufacturing instruments can obtain weight reductions of round 30% in comparison with typical designs. The AdTopoTool mission, led by Fraunhofer IWU alongside industrial companions Werkzeugbau Winkelmühle GmbH and H+E Produktentwicklung GmbH, used topology optimization and enhanced cooling channel designs to create lighter instruments with out sacrificing structural integrity.

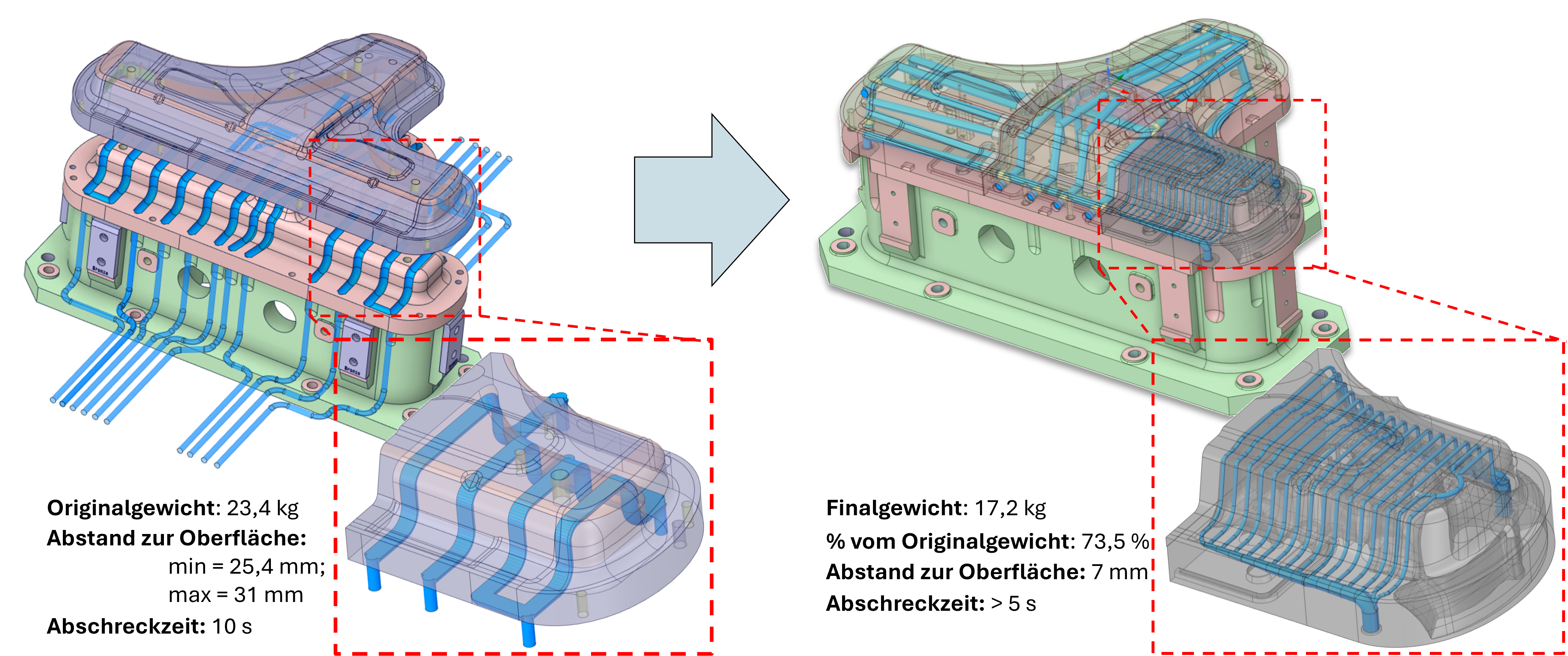

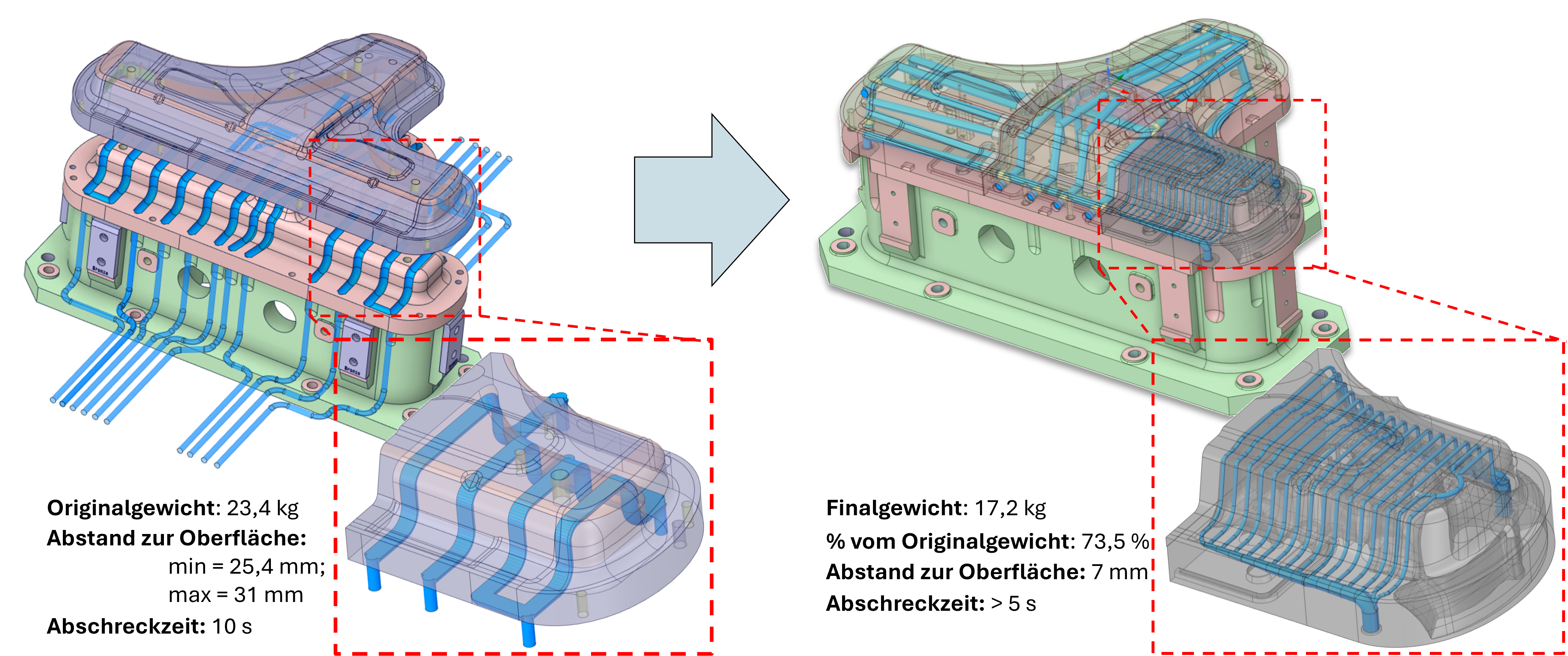

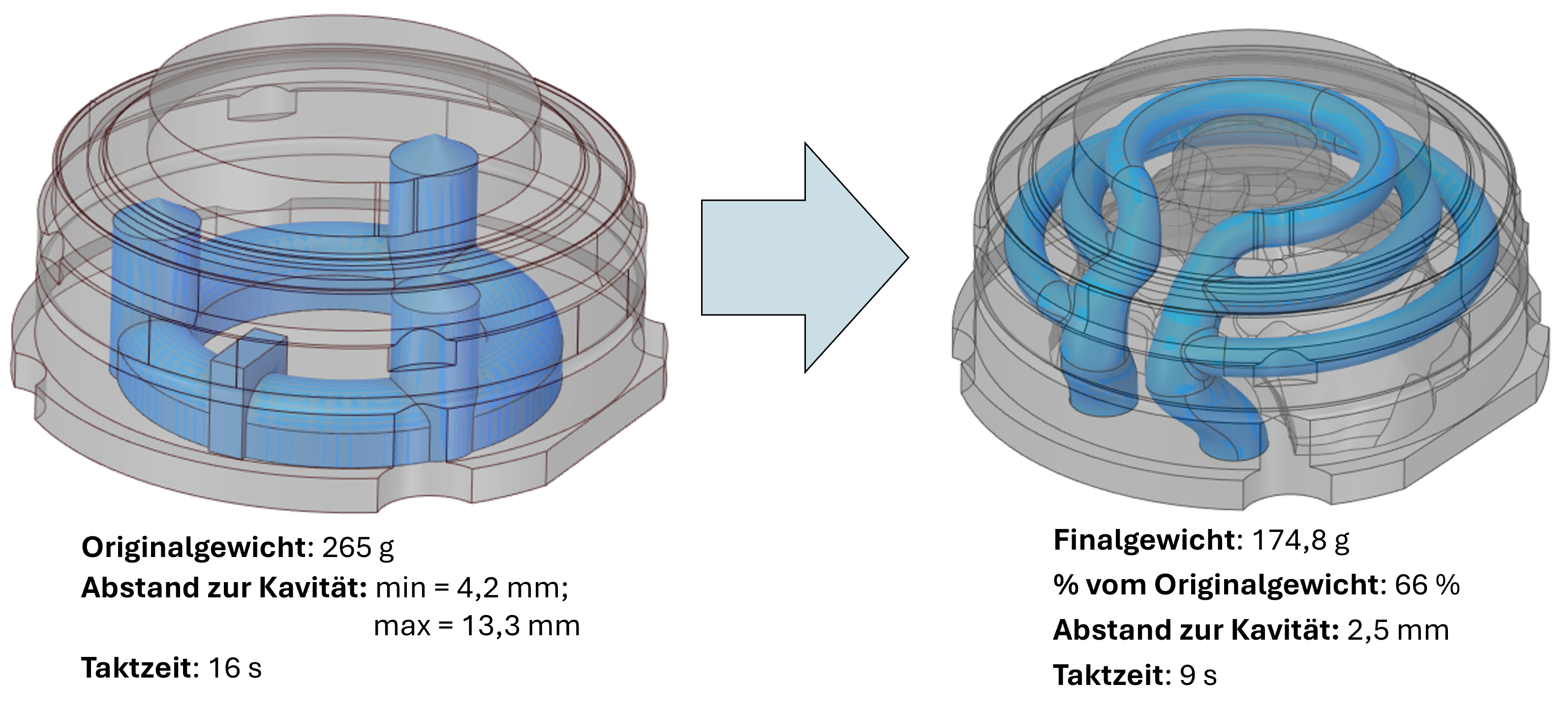

The analysis group developed numerical strategies to foretell how thermally pressured instruments behave below working circumstances. They utilized these strategies to create optimized device geometries for injection molding and press hardening functions. Testing confirmed a 34% weight discount for injection molding instruments and 28% for press hardening device segments whereas sustaining kind stability.

Past weight financial savings, the improved cooling methods delivered notable efficiency positive factors. Cycle occasions for injection-molded parts have been diminished by 60%, whereas warmth remedy occasions for press-hardened parts have been practically reduce in half. The researchers additionally reported enhancements in element high quality and dimensional accuracy in some instances.

Fraunhofer IWU is now engaged on a follow-up mission known as EWAM (Environment friendly Toolmaking with Additive Manufacturing) to deal with adoption limitations. The mission goals to develop automated software program instruments that may design temperature management methods for 3D printed manufacturing instruments. The deliberate software program plug-in can be suitable with numerous 3D CAD applications and use common programming languages to facilitate trade adoption.

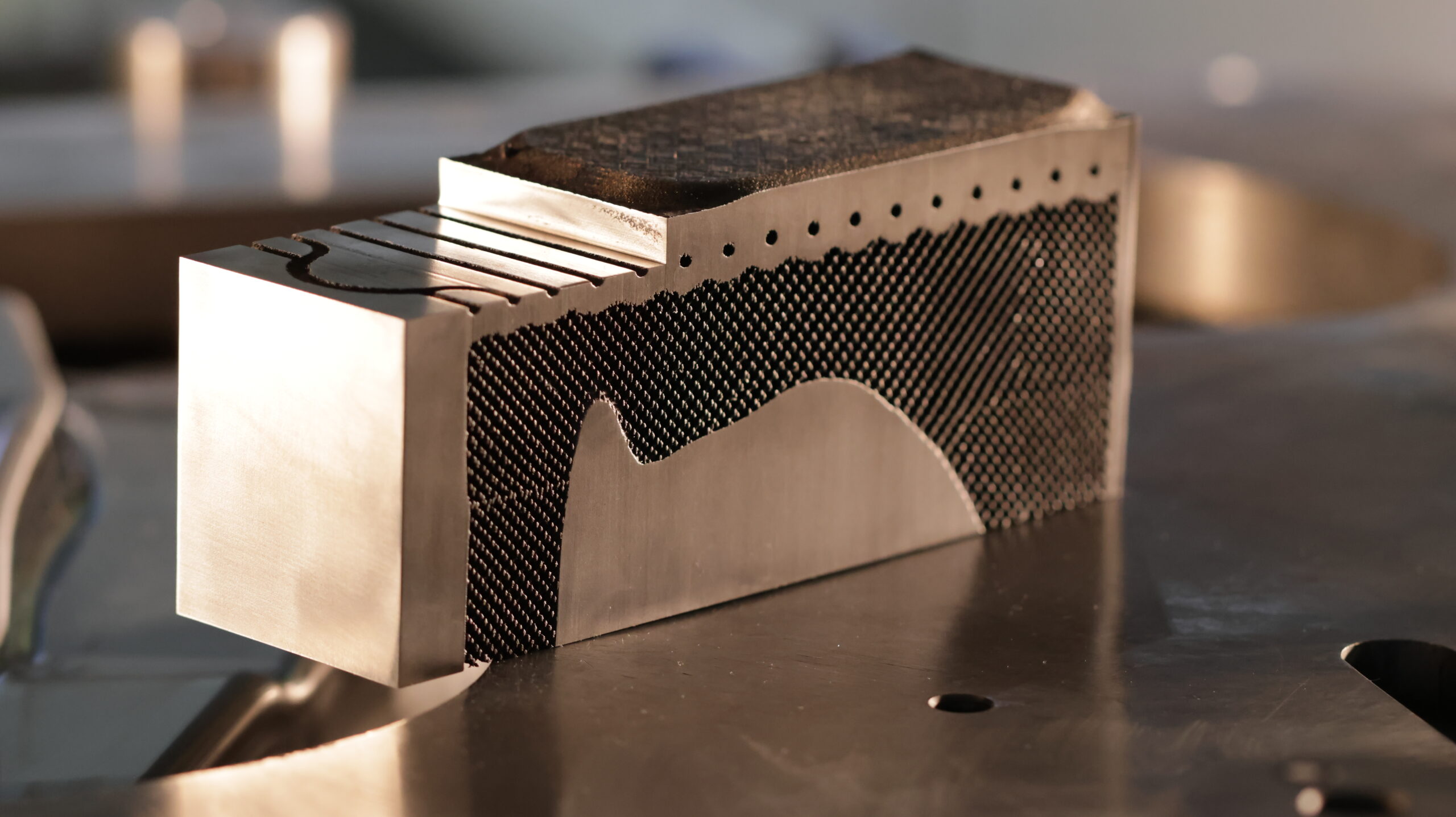

The analysis combines laser powder mattress fusion 3D printing with optimized geometries and clever cooling methods. Fraunhofer IWU expects this strategy to profit medium-sized device producers by offering quicker implementation and extra resource-efficient options.

Supply: iwu.fraunhofer.de