Engineers on the Princeton Plasma Physics Laboratory (PPPL) within the U.S. are getting ready for the meeting of the fusion analysis machine Nationwide Spherical Torus Experiment-Improve (NSTX-U) anticipated to start operations in 2026.

To make sure exact alignment of parts, they’ve created over 50 3D printed prototypes. Central to the NSTX-U is a magnet bundle that mixes a 19 ft. toroidal subject (TF) magnet with an ohmic heating (OH) coil.

Designed to hold as much as 4 million amps, the TF magnet will hook up with 12 exterior coils that stabilize the plasma throughout experiments. Wrapped round it, the OH coil will generate a 4-kilovolt electrical subject to induce present and warmth the plasma to temperatures required for fusion.

The challenge’s aim is to judge whether or not these smaller, spherical tokamaks can present a sensible and cost-effective answer for future fusion pilot vegetation.

“Using 3D-printed prototypes has been instrumental towards lowering threat and accelerating the schedule,” Dave Micheletti, the NSTX-U Undertaking Director and Deputy Affiliate Laboratory Director For Engineering. “It permits us to positively verify that parts will match collectively and eliminates the danger of rework as soon as closing meeting begins. It’s saving each money and time.”

High-quality-tuning meeting with 3D prints

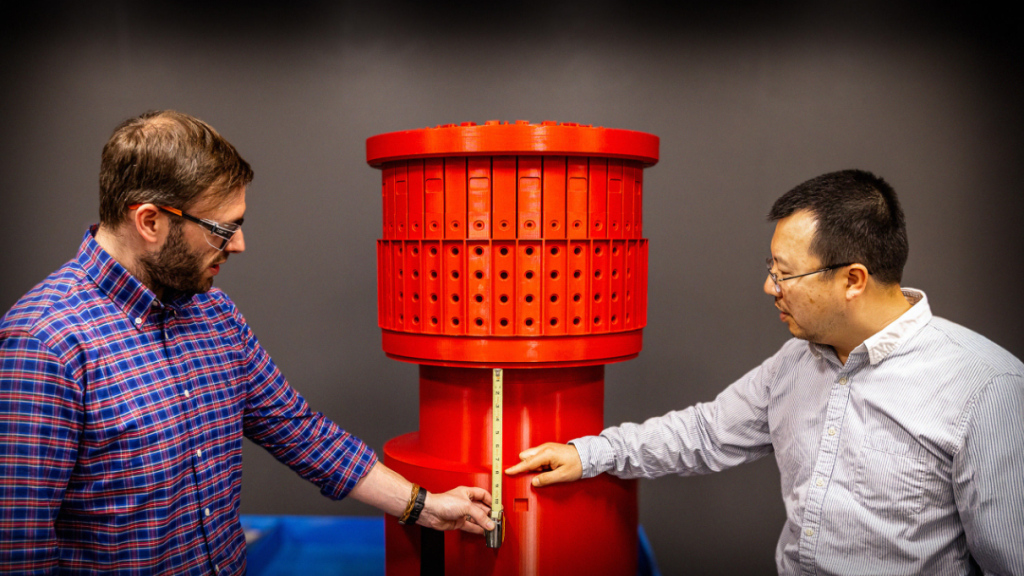

To scale back meeting dangers, engineers have used 3D printed fashions. These embrace an in depth, pink plastic duplicate of the magnet bundle’s high part, measuring 40 inches tall and a couple of ft. extensive, with plans for added massive fashions for the decrease sections.

“If it had been a Hollywood set and also you painted the TF-OH 3D print a unique shade, it might look similar to the machine,” stated Tom Jernigan, Senior Undertaking Supervisor on the NSTX-U challenge. “It’s the most effective cash we ever spent.”

In keeping with the workforce, 3D printing has additionally been instrumental in verifying the position of 36 cooling water strains extending from the highest of the magnet bundle, that are essential for managing the warmth of plasma experiments.

Different prototypes, together with copper electrical bus bars and varied assist constructions, have allowed the workforce to make exact changes earlier than manufacturing begins. Precise fabrication of the copper bus bars has already began, utilizing an OMAX water jet machine in PPPL’s workshop.

Preparations additionally contain becoming 2,000 protecting plasma-facing tiles within the vacuum vessel’s higher half, with plans to finish the decrease half quickly. Every tile have to be positioned inside tolerances of just some thousandths of an inch to endure the demanding situations of plasma testing.

In the meantime, Spanish equipment manufacturing firm Elytt Power technicians have constructed the 4 quadrants of the TF magnet and are presently compacting them along with metallic straps to make sure even stress on insulation layers.

They may subsequent wrap the quadrants in fiberglass and inject sizzling resin by way of vacuum stress impregnation (VPI) to create a single, stable magnet. As soon as the TF magnet is full, the OH coil can be wound round it and bear the identical course of.

The ultimate magnet bundle is anticipated to be accomplished by fall 2025. It’s going to then be shipped to PPPL for set up within the NSTX-U’s vacuum vessel. These thorough preparations are designed to eradicate setbacks and ensure the system’s readiness, bringing researchers nearer to evaluating whether or not spherical tokamak designs can assist the way forward for fusion vitality.

Improved reactor security with 3D printed parts

Throughout the broader nuclear sector, additive manufacturing is equally being harnessed to strengthen reactor parts and allow safer, extra environment friendly operations

Final 12 months, Westinghouse Electrical Firm developed distinctive filtering backside nozzles to spice up particles seize and enhance gasoline endurance in Pressurized Water Reactor (PWR) gasoline assemblies.

4 take a look at assemblies with these nozzles had been delivered to Southern Nuclear’s Joseph M. Farley Nuclear Plant in Alabama, specializing in tackling particles fretting, a number one reason for gasoline leaks. In keeping with the corporate, AM was important to refining the design, lowering the scale of particles that would enter the reactor, and attaining a 30% improve in particles resistance.

Talking with 3D Printing Business, specialists from Oak Ridge Nationwide Laboratory (ORNL), the most important vitality analysis lab within the U.S., defined how 3D printing advantages nuclear vitality. Professors Xin Solar and Kathy McCarthy shared that AM allows the manufacturing of superior reactor parts, equivalent to gasoline meeting brackets and channel fasteners, which enhance efficiency, security, and cut back prices.

They famous that 3D printing not solely simplifies manufacturing and cuts R&D time but additionally helps sensible parts that incorporate sensors and AI for safer nuclear operations. Whereas regulatory our bodies had been working to meet up with this new manufacturing paradigm on the time, ORNL licensed its 3D printing technique to Extremely Secure Nuclear Company (USNC), serving to to broaden 3D printing adoption within the nuclear sector.

Take the 3DPI Reader Survey — form the way forward for AM reporting in beneath 5 minutes.

What 3D printing developments do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals Samuel Sheckman, a mechanical engineer, left, and Danny Cai, a senior engineer, with the 3D mannequin of the highest of the toroidal subject coil. Photograph by way of PPPL.