Researchers on the College of Illinois Urbana-Champaign have developed a way to create constructions that may remodel from flat 2D shapes into curved 3D varieties utilizing low-energy activation. Aerospace Ph.D. pupil Ivan Wu and his advisor Jeff Baur mixed steady carbon fiber 3D printing with an energy-efficient resin system to handle the problem of transporting giant constructions like satellite tv for pc dishes into house.

The method makes use of a 3D printer to create bundles of carbon fibers, every in regards to the diameter of human hair, that are compressed and partially cured with ultraviolet mild. The printed design is then molded with liquid resin and frozen till wanted. When activated with low-energy warmth, a chemical response referred to as frontal polymerization cures the fabric into the specified 3D form.

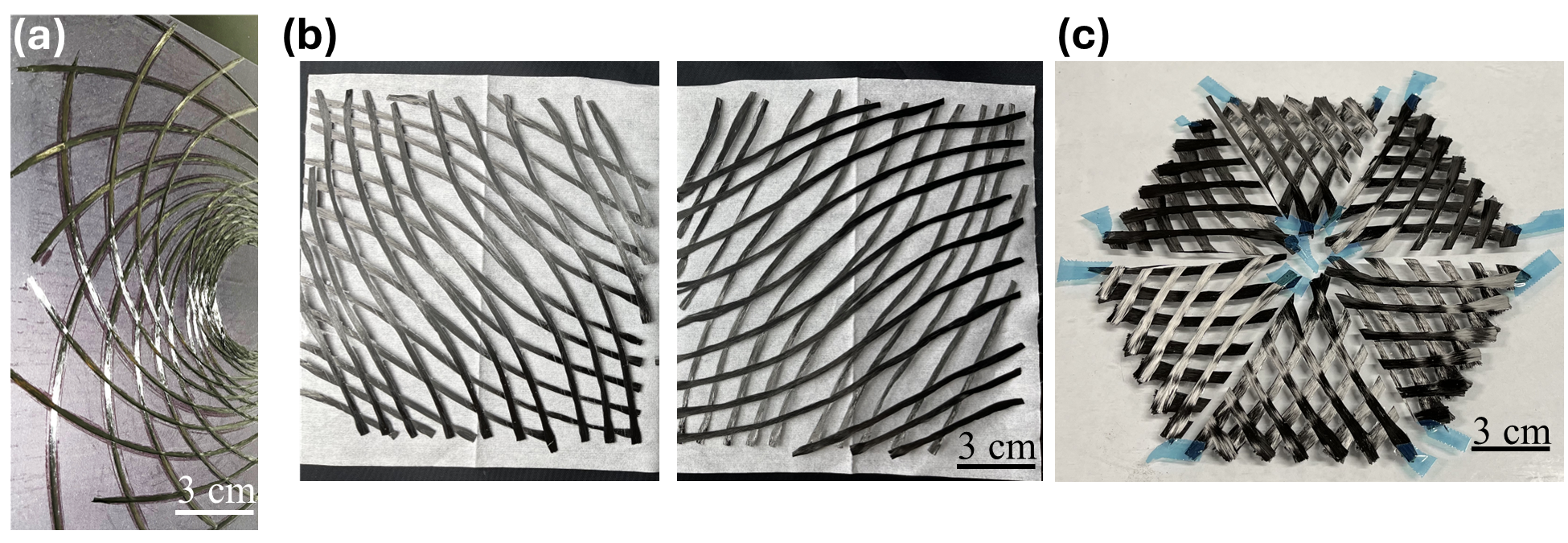

“For me, the primary problem was to resolve the inverse downside,” Wu stated. “You’ve got a design for the 3D form you need, however what’s the 2D sample to print that leads to that form? I needed to write mathematical equations to explain the shapes to print the precise sample.” Wu efficiently created 5 totally different configurations together with a spiral cylinder, twist, cone, saddle, and parabolic dish.

The strategy attracts inspiration from kirigami, a Japanese artwork kind that makes use of each cuts and folds. Wu famous that whereas the present stiffness ranges aren’t satisfactory for closing house constructions, the activated shapes can function molds for manufacturing higher-stiffness parts. The analysis, supported by the Air Drive Analysis Laboratory, was revealed in Additive Manufacturing with DOI: 10.1016/j.addma.2025.104911.

Supply: aerospace.illinois.edu