chain is a goal-oriented community of processes and inventory factors that delivers completed items to shops.

Think about a luxurious style retailer with a central distribution chain that delivers to shops worldwide (the USA, Asia-Pacific, and EMEA) from a warehouse situated in France.

When the retailer 158 situated at Nanjing West Street (Shanghai, China) wants 3 leather-based luggage (reference AB-7478) by Friday, a distribution planner creates a replenishment order.

This order is distributed to the warehouse for preparation and transport.

From this level on, the distribution planner loses direct management.

The cargo’s destiny is dependent upon a fancy distribution chain involving IT, warehouse, and transportation groups.

Nevertheless, if something goes mistaken, the planner is the one who has to elucidate why the shop missed gross sales resulting from late deliveries.

Every step is usually a supply of delays.

Why solely 73% of shipments had been delivered on time final week?

If shipments miss a cutoff time, this can be resulting from late order transmission, excessively lengthy preparation time, or a truck that departed the warehouse too late.

Sadly, static dashboards should not all the time ample to search out root causes!

Due to this fact, planners sometimes analyse the info (manually utilizing Excel) to establish the basis causes of every failure.

In my profession, I’ve seen total groups spend dozens of hours per week manually crunching knowledge to reply fundamental questions.

Probably the most sophisticated process in Provide Chain Administration is coping with individuals!

This can be a crucial function as a result of managers (transportation, warehouse, air freight) will all the time attempt to shift duty amongst themselves to cowl their very own groups.

As a result of root trigger evaluation is step one in steady enchancment, we should develop an answer to assist planners.

You’ll by no means resolve operational issues if you happen to can’t discover the basis causes.

Due to this fact, I wished to experiment with how an AI Agent can assist distribution planning groups in understanding provide chain failures.

I’ll ask the AI agent to resolve actual disputes between groups to find out whether or not one group is misinterpreting its personal KPIs.

The thought is to make use of the reasoning capabilities of Claude fashions to establish points from timestamps and boolean flags alone and to reply natural-language questions.

We would like the software to reply open questions with data-driven insights with out hallucinations.

What’s the duty of warehouse groups within the total efficiency?

These are precise questions that distribution planning managers should reply on a day-to-day foundation

This agentic workflow makes use of the Claude Opus 4.6 mannequin, linked by way of an MCP Server to a distribution-tracking database to reply our questions.

I’ll use a real-world situation to check the flexibility of the agent to assist groups in conducting analyses past what static dashboards can present:

- Clear up conflicts between groups (transportation vs. warehouse groups)

- Perceive the influence of cumulative delays

- Assess the efficiency of every leg

Perceive Logistics Efficiency Administration

We’re supporting a luxurious style retail firm with a central distribution warehouse in France, delivering to shops worldwide by way of street and air freight.

The Worldwide Distribution Chain of a Vogue Retailer

A group of provide planners manages retailer stock and generates replenishment orders within the system.

From this, a cascade of steps till retailer supply

- Replenishment orders are created within the ERP

- Orders are transmitted to the Warehouse Administration System (WMS)

- Orders are ready and packed by the warehouse group

- Transportation groups organise all the things from the pickup on the warehouse to the shop supply by way of street and air freight

On this chain, a number of groups are concerned and interdependent.

Our warehouse group can begin preparation solely after orders are obtained within the system.

Their colleagues within the transportation group anticipate the shipments to be prepared for loading when the truck arrives on the docks.

This creates a cascade of potential delays, particularly contemplating cut-off instances.

- Order Reception: if an order is obtained after 18:00:00, it can’t be ready the day after (+24 hours in LT)

- Truck leaving: if an order will not be packed earlier than 19:00:00, it can’t be loaded the identical day (+24 hours in LT)

- Arrival at Airport: in case your cargo arrives after 00:30:00, it misses the flight (+24 hours LT)

- Touchdown: in case your flight lands after 20:00:00, that you must wait an additional day for customs clearance (+24 hours LT)

- Retailer Supply: in case your vans arrive after 16:30:00, your shipments can’t be obtained by retailer groups (+24 hours LT)

If a group experiences delays, they’ll have an effect on the remainder of the chain and, finally, the lead time to ship to the shop.

Hopefully, we’re monitoring every step within the supply course of with timestamps from the ERP, WMS, and TMS.

For every factor of the distribution chain, we’ve:

- The timestamp of the completion of the duty

Instance: we document the timestamp when the order is obtained within the Warehouse Administration System (WMS) and is prepared for preparation. - A goal timing for the duty completion

For the step linked to a cut-off time, we generate a Boolean Flag to confirm whether or not the related cut-off has been met.

To be taught extra about how the Boolean flags are outlined and what’s a cut-off, you’ll be able to test this tutorial

Drawback Assertion

Our distribution supervisor doesn’t need to see his group manually crunching knowledge to know the basis trigger.

This cargo has been ready two hours late, so it was not packed on time and needed to wait the subsequent day to be shipped from the warehouse.

This can be a widespread problem I encountered whereas answerable for logistics efficiency administration at an FMCG firm.

I struggled to elucidate to decision-makers that static dashboards alone can’t account for failures in your distribution chain.

In an experiment at my startup, LogiGreen, we used Claude Desktop, linked by way of an MCP server to our distribution planning software, to assist distribution planners of their root-cause analyses.

And the outcomes are fairly fascinating!

How AI Brokers Can Analyse Provide Chain Failures?

Allow us to now see what knowledge our AI agent has readily available and the way it can use it to reply our operational questions.

We put ourselves within the footwear of our distribution planning supervisor utilizing the agent for the primary time.

P.S: These situations come from precise conditions I’ve encountered once I was accountable for the efficiency administration for worldwide provide chains.

Distribution Planning

We took one month of distribution operations:

- 11,365 orders created and delivered

- From December sixteenth to January sixteenth

For the enter knowledge, we collected transactional knowledge from the techniques (ERP, WMS and TMS) to gather timestamps and create flags.

A fast Exploratory Information Evaluation reveals that some processes exceeded their most lead-time targets.

On this pattern of 100 shipments, we missed the loading cutoff time for no less than six orders.

This means that the truck departed the warehouse en path to the airport with out these shipments.

These points probably affected the remainder of the distribution chain.

What does our agent have readily available?

Along with the lead instances, we’ve our boolean flags.

These booleans measure if the shipments handed the method on time:

- Transmission: Did the order arrive on the WMS earlier than the cut-off time?

- Loading: Are the pallets within the docks when the truck arrived for the pick-up?

- Airport: The truck arrived on time, so we wouldn’t miss the flight.

- Customized Clearance: Did the flight land earlier than customs closed?

- Supply: We arrived on the retailer on time.

For barely lower than 40% of shipments, no less than one boolean flag is about to False.

This means a distribution failure, which can be attributable to a number of groups.

Can our agent present clear and concise explaination that can be utilized to implement motion plans?

Allow us to check it with advanced questions.

Take a look at 1: A distribution planner requested Claude in regards to the flags

To familiarise herself with the software, she started the dialogue by asking the agent what he understood from the info accessible to him.

This demonstrates that my MCP implementation, which makes use of docstrings to outline instruments, conforms to our expectations for the agent.

Take a look at 2: Difficult its methodology

Then she requested the agent how we’d use these flags to evaluate the distribution chain’s efficiency.

On this first interplay, we sense the aptitude of Claude Opus 4.8 to know the complexity of this train with the minimal info offered within the MCP implementation.

Testing the agent with real-world operational situations

I’m now sufficiently assured to check the agent on real-world situations encountered by our distribution planning group.

They’re answerable for the end-to-end efficiency of the distribution chain, which incorporates actors with divergent pursuits and priorities.

Allow us to see whether or not our agent can use timestamps and boolean flags to establish the basis causes and arbitrate potential conflicts.

Nevertheless, the actual check will not be whether or not the agent can learn knowledge.

The query is whether or not it may possibly navigate the messy, political actuality of distribution planning, the place groups blame each other and dashboards might obscure the reality.

Let’s begin with a difficult state of affairs!

Situation 1: difficult the native last-mile transportation group

In accordance with the info, we’ve 2,084 shipments that solely missed the newest boolean flag Supply OnTime.

The central group assumes that is as a result of last-mile leg between the airport and the shop, which is underneath the native group’s duty.

For instance, the central group in France is blaming native operations in China for late deliveries in Shanghai shops.

The native supervisor disagrees, pointing to delays on the airport and through customs clearance.

P.S.: This situation is widespread in worldwide provide chains with a central distribution platform (in France) and native groups abroad (within the Asia-Pacific, North America, and EMEA areas).

Allow us to ask Claude if it may possibly discover who is true.

Claude Opus 4.6 right here demonstrates precisely the behaviour that I anticipated from him.

The agent supplies nuance by evaluating the flag-based strategy to static dashboards with an evaluation of durations, due to the instruments I outfitted it with.

This states two issues:

- Native group’s efficiency (i.e. Airport -> Retailer) will not be worse than the upstream legs managed by the central group

- Shipments go away the airport on time

This means that the downside lies between takeoff and last-mile retailer supply.

That is precisely what Claude demonstrates under:

The native group will not be the one explanation for late deliveries right here.

Nevertheless, they nonetheless account for a big share of late deliveries, as defined in Claude’s conclusion.

What did we be taught right here?

- The native group accountable nonetheless wants to enhance its operations, however it isn’t the one social gathering contributing to the delays.

- We have to talk about with the Air Freight group the variability of their lead instances, which impacts total efficiency, even once they don’t miss the cut-off instances.

In Situation 1, the agent navigated a disagreement between headquarters and a neighborhood group.

And it discovered that either side had a degree!

However what occurs when a group’s argument is predicated on a elementary misunderstanding of how the KPIs work?

Situation 2: a combat between the warehouse and the central transportation groups

Now we have 386 shipments delayed, the place the solely flag at False is Loading OnTime.

The warehouse groups argue that these delays are as a result of late arrival of vans (i.e., orders ready and prepared on time had been awaiting truck loading).

Is that true? No, this declare is because of a misunderstanding of the definition of this flag.

Allow us to see if Claude can discover the correct phrases to elucidate that to our distribution planner.

As a result of we shouldn’t have a flag indicating whether or not the truck arrived on time (solely a cutoff to find out whether or not it departed on time), there may be some ambiguity.

Claude will help us to make clear that.

For this query, Claude precisely did what I anticipated:

- It used the software to analyse the distribution of lead instances per course of (Transmission, Choosing and Loading)

- Defined the correct significance of this flag to the distribution planner in the important thing perception paragraph

Now that the distribution planner is aware of that it’s mistaken, Claude will present the correct components to reply to the warehouse group.

Not like within the first situation, the comment (or query) arises from a misunderstanding of the KPIs and flags.

Claude did a terrific job offering a solution that is able to share with the warehouse operations group.

In Situation 1, each groups had been partially proper. In Situation 2, one group was merely mistaken.

In each circumstances, the reply was buried within the knowledge, not seen on any static dashboard.

What can we be taught from these two situations?

Static dashboards won’t ever settle these debates.

Even when they’re a key a part of Logistic Efficiency Administration, as outlined on this article, they’ll by no means absolutely clarify all late deliveries.

They present what occurred, not why, and never who’s really accountable.

Distribution planners know this. That’s why they spend dozens of hours per week manually crunching knowledge to reply questions their dashboards can’t.

Slightly than making an attempt to construct a complete dashboard that covers all situations, we will concentrate on a minimal set of boolean flags and calculated lead instances to assist customized analyses.

These analyses can then be outsourced to an agent, resembling Claude Opus 4.6, which can use its data of the info and reasoning abilities to offer data-driven insights.

We are able to even use it to generate interactive visuals to convey a particular message.

Within the visible above, the thought is to indicate that relying solely on Boolean flags might not absolutely replicate actuality.

Flag-Based mostly attribution was in all probability the supply of quite a bit conflicts.

All of those visuals had been generated by a non-technical consumer who communicated with the agent utilizing pure language.

That is AI-powered analysis-as-a-service for provide chain efficiency administration.

Conclusion

Reflecting on this experiment, I anticipate that agentic workflows like this can exchange an growing variety of reporting initiatives.

The benefit right here is for the operational groups.

They don’t have to depend on enterprise intelligence groups to construct dashboards and experiences to reply their questions.

Can I export this PowerBI dashboard in Excel?

These are widespread questions it’s possible you’ll encounter when growing reporting options for provide chain operations groups.

It’s as a result of static dashboards won’t ever reply all of the questions planners have.

With an agentic workflow like this, you empower them to construct their very own reporting instruments.

The distribution planning use case centered on diagnosing previous failures. However what about future choices?

We utilized the identical agentic strategy, utilizing Claude linked by way of MCP to a FastAPI optimisation engine, to a really completely different downside: Sustainable Provide Chain Community Design.

The purpose was to assist provide chain administrators in redesigning the community inside the context of the sustainability roadmap.

The place ought to we produce to attenuate the environmental influence of our provide chain?

Our AI agent is used to run a number of community design situations to estimate the influence of key choices (e.g., manufacturing unit openings or closures, worldwide outsourcing) on manufacturing prices and environmental impacts.

The target is to offer decision-makers with data-driven insights.

This was the primary time I felt that I might be changed by an AI.

The standard of this evaluation is similar to that produced by a senior marketing consultant after weeks of labor.

Claude produced it in seconds.

Extra particulars on this tutorial,

Do you need to be taught extra about distribution planning?

Why Lead Time is Vital?

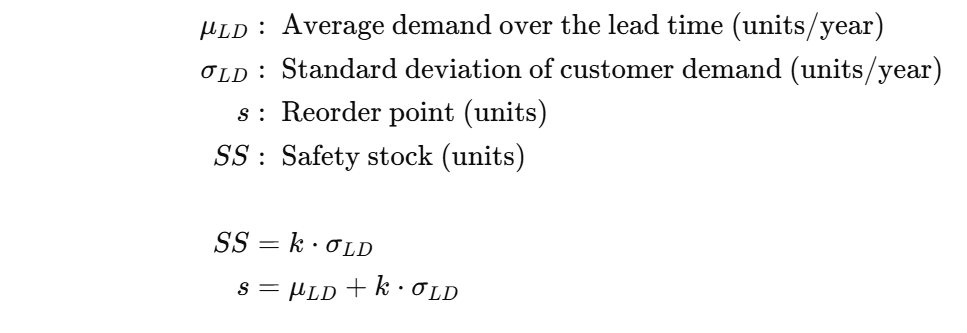

Provide Planners use Stock Administration Guidelines to find out when to create replenishment orders.

These guidelines account for demand variability and supply lead time to find out the optimum reorder level that covers demand till items are obtained.

This reorder level is dependent upon the common demand over the lead time.

However we will adapt it based mostly on the precise efficiency of the distribution chain.

For extra particulars, see the entire tutorial.

About Me

Let’s join on LinkedIn and Twitter; I’m a Provide Chain Engineer utilizing knowledge analytics to enhance logistics operations and cut back prices.

For consulting on analytics and sustainable provide chain transformation, be at liberty to contact me by way of Logigreen Consulting.

You probably have any questions, you’ll be able to go away a remark in my app: Provide Science.