Learn all the largest 3D printing tales of 2024 within the 3D Printing Business Assessment of the Yr.

In April, enterprise information continued to dominate the headlines. Two of essentially the most influential additive manufacturing consultancies revealed annual market stories highlighting key business tendencies, evaluation, and forecasts for the way forward for 3D printing. Notably, the stories featured starkly contrasting 3D printing market measurement estimations.

Elsewhere, GE Aerospace debuted as an impartial firm on the New York Inventory Trade following Basic Electrical’s restructuring. Solidscape additionally went solo after a non-public investor acquisition, whereas Markforged was ordered to pay $17.34 million in a patent-infringement lawsuit.

Sustainability was one other key theme in April, with a number of corporations saying eco-friendly additive manufacturing initiatives. Moreover, the deal with strengthening home provide chains within the US continued with efforts to re-shore the manufacturing of batteries and missiles. Medical purposes have been additionally spotlighted, with one analysis institute 3D printing ultra-realistic coronary heart and lung fashions.

Learn on for 3D printing updates from Stratasys, MIT, Ursa Main, 6K Power, Farsoon Applied sciences, Meltio, AML3D, and extra.

What’s the 3D printing market measurement?

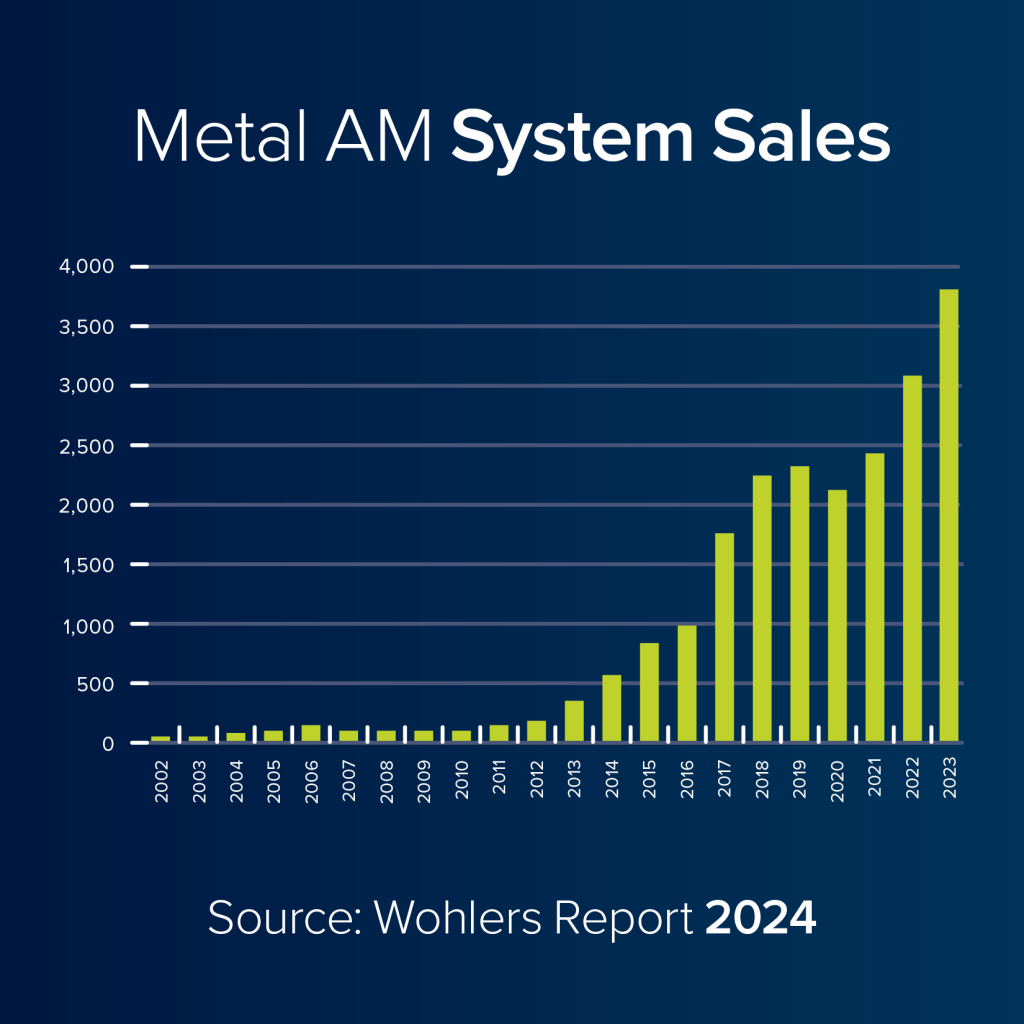

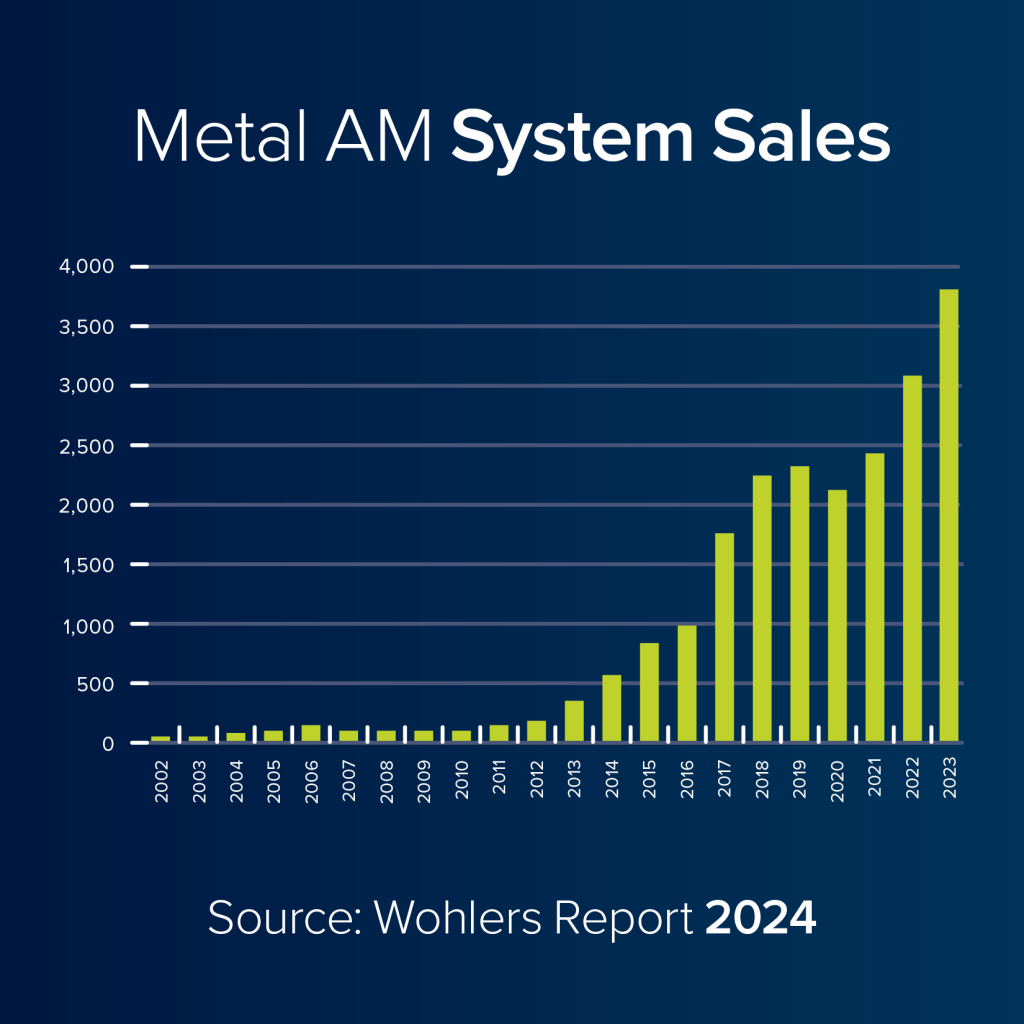

In April, Wohlers Associates, the Colorado-based additive manufacturing consultancy agency working below ASTM Worldwide, launched its Wohlers Report 2024. This outlined that the business had grown 11.1% to a 3D printing market valuation of $20.035 billion, exceeding $20 billion for the primary time.

The report’s principal writer, Terry Wohlers, advised 3D Printing Business that the market measurement is definitely “a lot bigger than what we report.” He defined that the estimate excludes capital spent on 3D printing inside organizations like Adidas, NASA, and Stryker. The determine additionally omits the worth of analysis, improvement, prototyping, tooling, and components 3D printed by authentic gear producers.

Trying to the way forward for 3D printing, the report anticipates a shift to the high-volume manufacturing of end-use components. Wohlers predicts that manufacturing will transfer from 1000’s of components to a whole bunch of 1000’s. Million-part manufacturing runs are additionally anticipated for small elements.

German consultancy AMPOWER reported a 3D printing market measurement of simply €10.5 million for 2023, roughly half of the Wohlers determine. This estimate, revealed within the AMPOWER 2024 report, represents a ten.3% improve in comparison with the earlier 12 months’s estimation. Metallic powder mattress fusion 3D printers reportedly accounted for 40% of gross sales 2023 income. Moreover, sturdy development was seen within the aerospace and protection sectors, with a 30% improve over the previous two years. The rise in world protection budgets is anticipated to drive the adoption of additive manufacturing additional. Nevertheless, the automotive sector’s funding in 3D printing stagnated in 2023, whereas startup funding declined resulting from an absence of world enterprise capital.

AMPOWER projected regular business development, forecasting an annual development price of 13.9% and €20 billion in revenues by 2028. Gear suppliers within the Asia-Pacific (APAC) area are anticipated to expertise an annual development price of round 16% till 2028.

3D printing enterprise updates

April noticed GE Aerospace debut on the New York Inventory Trade as an impartial public firm following GE’s operational restructuring. This resulted within the creation of three impartial corporations: GE HealthCare, GE Vernova, and GE Aerospace. Metallic 3D printer producer Colibrium Additive, rebranded from GE Additive, is a part of GE Aerospace’s Propulsion & Additive Applied sciences (PAT) division.

A joint opening bell ceremony alongside GE Vernova was held on April 2, 2024. The aerospace producer entered the market with a sizeable put in base, together with 44,000 industrial engines and 26,000 navy engines worldwide.

One other firm that introduced its independence was high-resolution 3D printing specialist Solidscape. Recognized for its 3D printers for the jewellery and precision funding casting industries, the corporate was acquired by a non-public investor. This fashioned a part of a strategic transfer to bolster Solidscape’s presence and innovation within the jewellery 3D printing market.

This announcement adopted the information in January that Prodways had discontinued the Solidscape product line of wax and resin 3D printers, which had carried out poorly in 2023. Following the acquisition, Solidscape will proceed to supply its vary of 3D printers and supplies for jewellery purposes. The corporate additionally confirmed its dedication to growing new merchandise and enhancing current applied sciences.

Elsewhere, Canadian 3D printing powder developer Equispheres raised roughly CAD 20 million in a Sequence B funding spherical. Martinrea Worldwide led the spherical, whereas INFOR Monetary and Stifel Nicolaus Canada acted as monetary advisors. The corporate deliberate to leverage this capital throughout numerous essential efforts, together with new reactors to scale its manufacturing capabilities.

In authorized information, 3D printer producer Markforged was ordered to pay Steady Composites $17.34 million as a part of a patent infringement lawsuit that started in 2021. A federal jury within the US District Courtroom for the District of Delaware discovered that a number of of the corporate’s 3D printers infringed on a patent protecting the strategy and equipment for steady composite 3D printing. In a press release, Markeforged commented that it “strongly disagrees with this verdict” and outlined intentions to “overturn the decision in post-trial motions.”

Later this 12 months, Markforged settled with Steady Composites after agreeing to pay the corporate $25 million. The deal, which included a Patent License Settlement, resolved all claims and counterclaims within the IP dispute.

Sustainable manufacturing initiatives

The sustainability of additive manufacturing was a key speaking level in April. The month noticed main 3D printer producer Stratasys publish its second environmental, social, governance, and sustainability report. This highlighted the environmental sustainability and social affect of the corporate’s 3D printing expertise.

Stratasys acknowledged that it’s delivering on the ‘conscious manufacturing’ commitments it made in its 2022 report, claiming its expertise permits producers to transition to extra sustainable practices. The corporate additionally highlighted a number of environmental, social, and governance-based achievements.

Most impressively, Stratasys introduced it decreased 207 metric tons of CO2 emission by adopting renewable power at its services. The corporate put in photo voltaic panels at its Israel services, producing 441,339 kWh of renewable power. It additionally claimed to have decreased 3D printing waste by its recycling program. This elevated the variety of recycled filament spools, cartridges, and canisters by 11.3%.

Later within the month, a staff from the Massachusetts Institute of Know-how (MIT) developed an FDM 3D printer that may autonomously create parameters for unknown supplies. This technique seeks to extend the adoption of distinctive 3D printing filaments which can be extra sustainable than hard-to-recycle, fossil fuel-based polymers.

Additionally focusing on recycling was UK-based 3D printing filament producer Filamentive, which launched its free 3D Printing materials recycling service. Stated to be the primary scheme of its variety within the UK, it permits current Filamentive clients to return their PLA waste freed from cost. 100% of this materials is then recycled into new merchandise.

The corporate hopes this can fight growing 3D printing-related plastic air pollution. In response to Filamentive, 33% of 3D printed components find yourself as waste, translating to 400,000 kg of plastic within the UK every year

On the powder facet, the AMGTA revealed the outcomes of its research on essentially the most sustainable metallic 3D printing supplies. The findings counsel that helium gasoline atomization is essentially the most energy-efficient methodology for producing widespread metallic powders. This reportedly makes use of 13% much less power per kilogram of powder in comparison with argon and 28% lower than nitrogen for widespread alloys.

Re-shoring manufacturing within the US

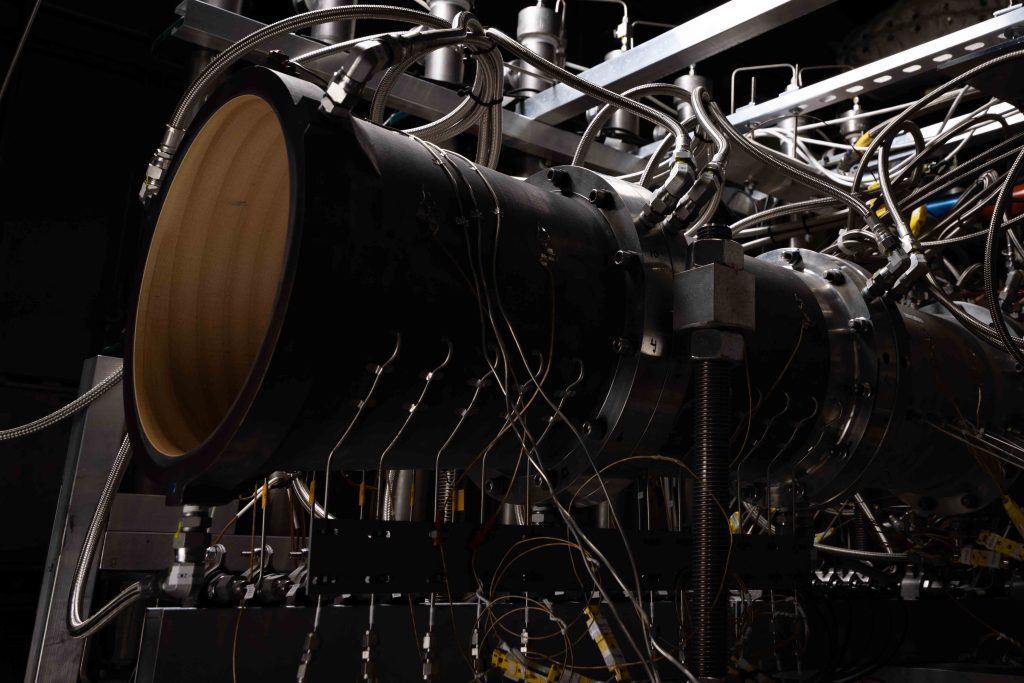

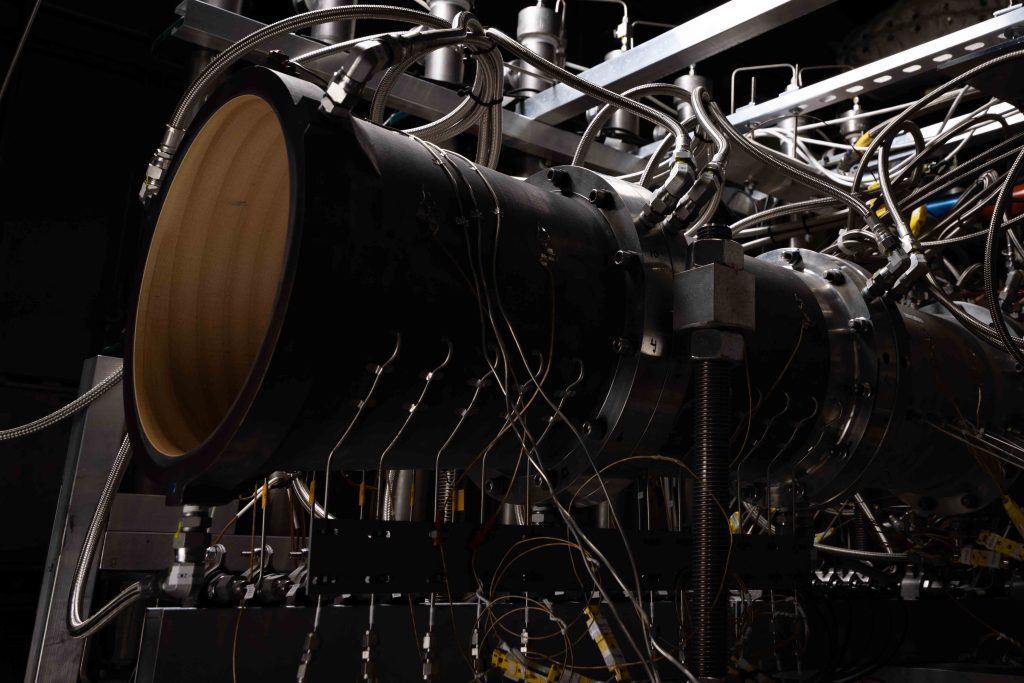

In April, efforts to re-shore manufacturing within the US ramped up. Inside the protection sector, rocket engine producer Ursa Main signed a contract with the US Navy to design and take a look at a 3D printed stable rocket motor (SRM) for the Customary Missile program.

This settlement sees the corporate leverage its additive manufacturing-based Lynx expertise to design the following era of SRMs optimized for reliability and manufacturability.

The mission goals to create a brand new 3D printable design for the Mk 104 twin rocket motor, addressing challenges related to conventional manufacturing strategies. The Mk 104 powers the SM-2, SM-3, and SM-6 missiles. This 12 months, demand for missiles in America surged resulting from a scarcity of home suppliers, the necessity to replenish US stockpiles, and ongoing help for Ukraine’s conflict efforts.

Additionally in April, a large-scale ARCEMY ‘X-Version 6700’ 3D printer from AML3D grew to become absolutely operational on the US Navy’s Additive Manufacturing Heart of Excellence in Danville, Virginia. Price AUD$1.1 million, the Wire Arc Additive Manufacturing system was bought by the Australian 3D printer producer’s US ‘Scale-Up’ technique, which delivered over AUD$12 million in orders final 12 months. This initiative seeks to deal with provide challenges throughout the US Division of Protection, significantly the US Navy’s submarine industrial base.

Away from protection manufacturing, 6K Power, a division of superior materials specialist 6K, signed a strategic provide settlement with metallic recycling agency Aqua Metals. By means of this partnership, the businesses are working to construct a round provide chain for lithium-ion battery supplies in the US.

The collaboration sees Aqua Metals provide 6K with recycled battery supplies from its Sierra ARC facility in Reno. 6K then makes use of its UniMelt microwave plasma expertise to transform these essential supplies into cathode lively supplies at its PlusCAM manufacturing unit in Jackson, Tennessee. Recycled battery supplies are later bought to US-based producers.

This aligns with the US Authorities’s efforts to re-shore its manufacturing capabilities amid world provide chain challenges. By 2030, the lithium-ion battery manufacturing capability within the US is anticipated to succeed in almost one terawatt-hour.

Assist-free metallic 3D printing

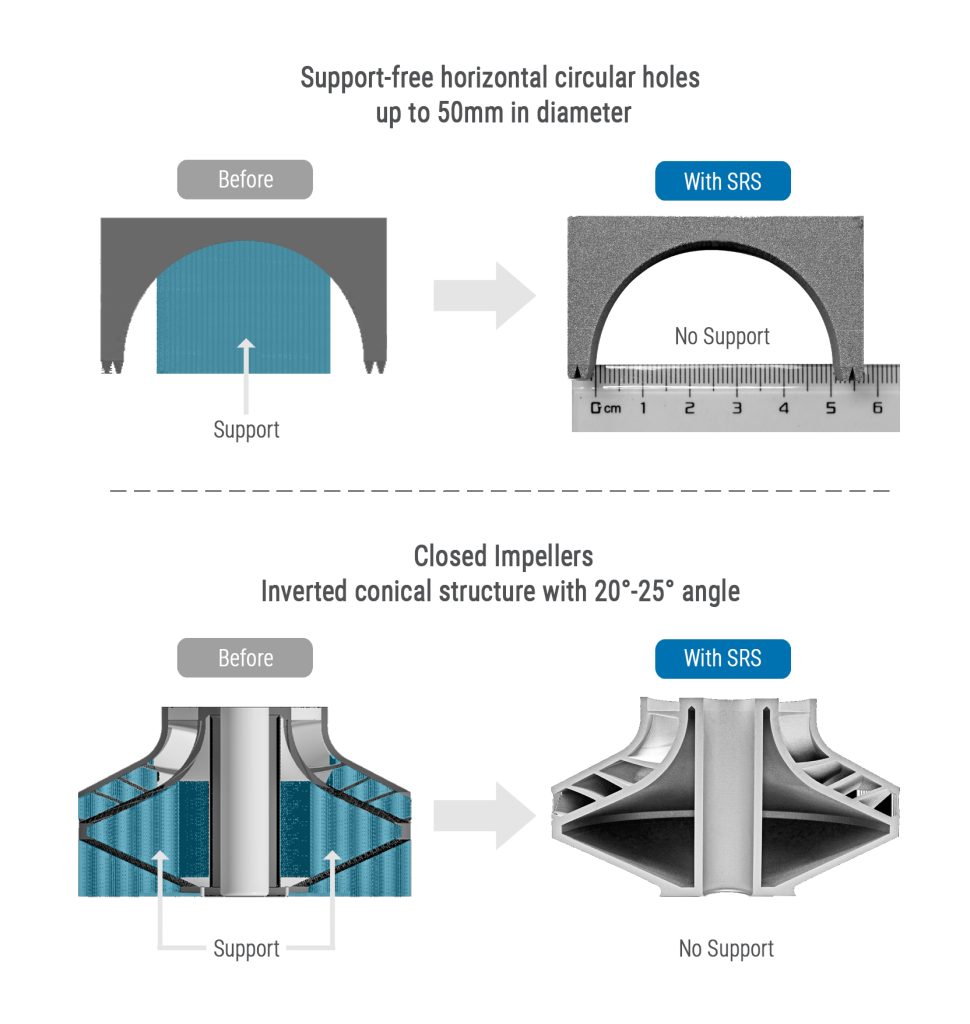

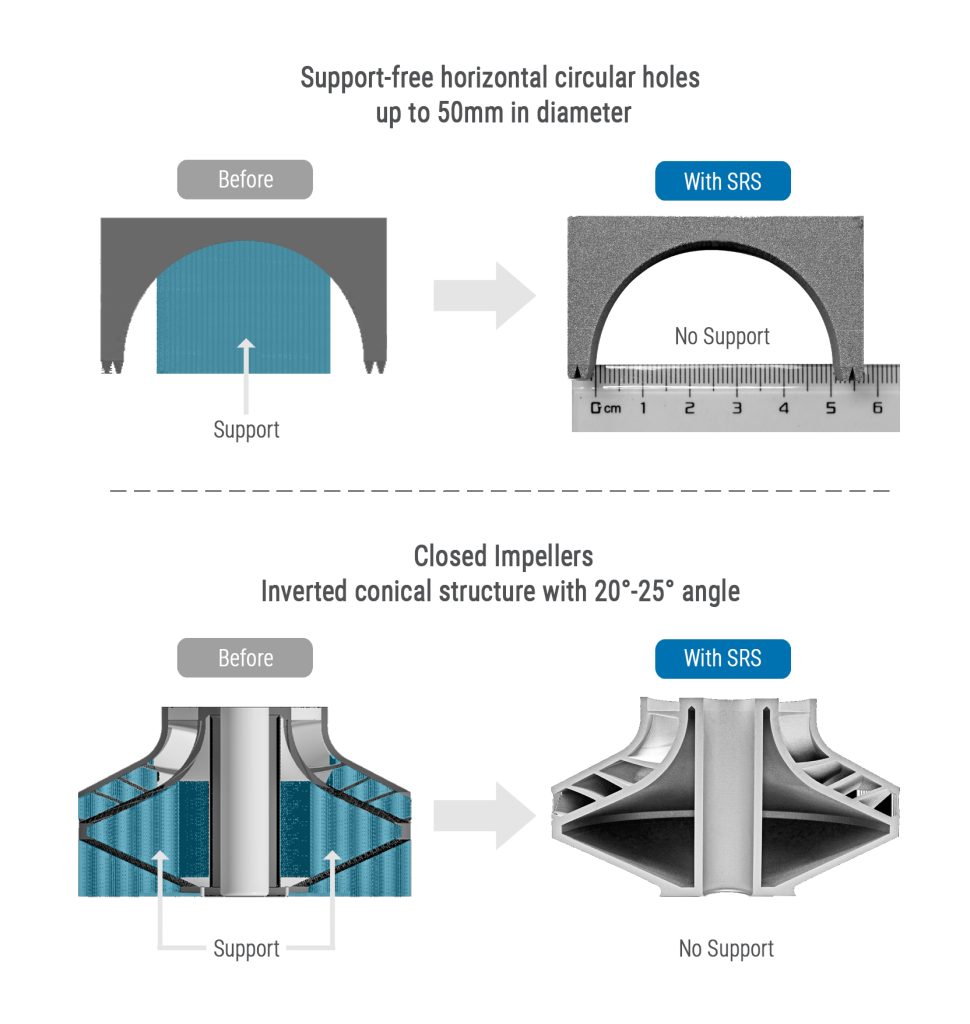

In April, a key improvement in metallic 3D printing got here from Farsoon Applied sciences. The Chinese language 3D printer producer launched its Assist Discount System to deal with widespread support-based challenges in metallic powder mattress fusion 3D printing.

In response to Farsoon, the expertise combats stress and warping in the course of the cooling course of after 3D printing. This typically causes components to crack, particularly in overhanging areas. The brand new expertise facilitates dependable, support-free 3D printing of inverted conical constructions with angles between 20 and 25°, and spherical holes as much as 50 mm broad.

These capabilities scale back materials necessities, translating to vital value financial savings, slicing time commitments, and minimizing harm related to help removing. The expertise additionally facilitates the creation of extra intricate half geometries, creating the potential for beforehand unachievable options.

3D printing medical units

The growing adoption of 3D printing for medical purposes was additionally evident this month. Researchers from Nottingham Trent College produced sensible 3D printed coronary heart and lung fashions that bleed, beat, and breathe like their actual counterparts.

Focused to organ transplant coaching purposes, the guts fashions replicate the tactile qualities of the actual factor. They are often produced with totally different tissue hardness ranges, permitting surgeons to plan operations.

The 3D printed organs may also be used to analysis and educate transplant procedures. Most trainee surgeons at present apply with cadavers and animal organs, as current fashions aren’t sensible sufficient. The researchers declare their 3D printed fashions are the primary to supply the realism required for medical coaching.

Elsewhere, biomedical 3D printing agency ArcomedLab introduced that it had established the world’s largest case record of 3D printed craniomaxillofacial implants. By April 2024, the agency had accomplished 700 profitable circumstances all through Latin America, together with in Chile, Peru, Colombia, and Mexico.

The implants have been 3D printed in a PEEK biopolymer materials and customized to fulfill particular affected person wants. They will additionally retailer and ship liquid medicine on the level of want by the corporate’s patented gravity-induced drip mechanism. This permits medicine to be administered as much as 20 days after surgical procedure.

3D Printing Information Highlights from 2024: Improvements, Developments, and Evaluation

All of the information from Formnext 2024.

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

It’s also possible to observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits a US Navy SM-6 missile. Photograph through the US Navy.