Formnext 2025 marked the tenth anniversary of the world’s largest additive manufacturing occasion with over 38,000 guests trying to see what’s subsequent for 3D printing.

The 3D Printing Trade group spent the week in Frankfurt, and offered a relentless feed of reports from the occasion. On this article we’ve gathered collectively virtually 60 articles to supply a complete assessment of all of the information from Formnext 2025.

Are these firms main the business? Make your nominations for the 3D Printing Trade Awards now.

With 804 exhibitors (2024: 864) unfold throughout roughly 50,000 sq. meters (2024: 54,000 m²), elements of the present flooring felt busier and extra globally related. Maybe reflecting the sheer quantity of machines, the desktop 3D printer firms skilled a better footfall than the commercial enterprises.

Throughout the cubicles and phases, some producers unveiled subsequent era metallic and polymer methods, greater efficiency supplies, smarter automation, and AI assisted workflows that trace at the way forward for manufacturing. Different firms had been content material to speak evolution fairly than revolution, and more and more the business appears extra immune to the urge to launch a “new” product at a tempo tied to the frequency of commerce exhibits.

“Additive Manufacturing is now not a promise for the long run, however a actuality in quite a few industries,” stated Sascha F. Wenzler, Vice President Formnext at Mesago Messe Frankfurt GmbH. “With progress, nevertheless, come new challenges. And that is precisely the place Formnext is available in: It showcases options for the continuing industrialization of AM, larger supply-chain flexibility, and the know-how’s elevated accessibility for SMEs.”

Missed out on the information? Learn on beneath to get a full Formnext 2025 recap of all of the displays, and launches from AiBuild, Bambu Lab, Prusa Analysis, Stratasys, and others.

3D printers and system upgrades

Kicking off with 3D printers, UK-based 3D printing software program developer Aibuild and robotics engineering startup Generative Machine launched a desktop 5-axis FFF 3D printer that mixes superior movement {hardware} with automated course of management, enabling multi-directional printing that minimizes helps and improves floor high quality and half energy.

Constructed utilizing Autodesk Fusion 360 and built-in with Duet3D movement management, the machine shifts from earlier {hardware} growth to software-driven automation, including parametric slicing and multi-axis toolpath optimization. Demonstrations deliberate for Formnext 2025 highlighted that this growth goals to convey industrial-grade geometric freedom to smaller customers.

From East Asia, Shanghai-based 3D printer producer UnionTech launched two new industrial SLA methods, the RSPro800 X and RA900, increasing its end-to-end providing for automotive prototyping, funding casting, and tyre-mould manufacturing. Described because the business’s first four-laser large-format SLA printer, The RSPro800 X delivers as much as 60% quicker printing, ±0.1 mm accuracy, and an 800 × 800 × 550 mm construct quantity, supported by UT-ONE digital workflows.

The RA900 targets tyre-mould manufacturing with a 950 × 550 × 400 mm construct space, Ra ≤3.5 µm surfaces, and manufacturing cycles lowered to 2–4 days. Reside demonstrations showcased accelerated workflows and scalable digital manufacturing.

The brand new PROline metallic AM system from One Click on Steel was showcased on the tradeshow, demonstrating its capabilities for patrons transferring from prototyping to industrial manufacturing. The platform facilities on the MPRINTpro metallic 3D printer with a 500 W laser enabling quicker construct charges, thicker layers, and processing of higher-energy supplies.

Developed with Herding Filtertechnik, a key improve is its self-cleaning filter providing as much as 500 hours of maintenance-free operation. Paired with the MPUREpro unit that includes vacuum-assisted powder dealing with for bigger volumes, the system streamlines unpacking, sieving, and materials reuse for environment friendly collection manufacturing workflows.

Superior equipment producer DN Options used the DLX 450 metallic 3D printer and the DVF 5000 2nd Gen machining heart to reveal how additive and subtractive processes can function as a unified workflow. The DLX 450 introduced consideration to its giant 450 × 450 × 450 mm construct area, multi-laser Yb fiber structure, and seven m/s scanning, enabling speedy manufacturing of advanced metallic elements.

Guests then noticed how the DVF 5000 2nd Gen with its 15,000 rpm spindle, 230 Nm torque, and 28-position Multi-AWC can take these printed parts immediately into high-precision ending, showcasing DN Options’ imaginative and prescient for related industrial manufacturing.

Moreover, the brand new STLR 120 by India’s amace options was displayed as a compact laser powder mattress fusion (LPBF) system tailor-made for analysis labs, startups, and medtech builders. Providing a Ø120 × 200 mm construct quantity and a 400 W fiber laser, it allows speedy iteration with first builds requiring below 1 kg of powder and helps supplies from AlSi10Mg to Ti-6Al-4V.

Construct prep runs on Materialise Magics Print LM, whereas its single-phase, small-footprint design fits college environments. A demo unit is already put in at AceMicromatic Worldwide GmbH for take a look at builds and evaluations.

German 3D printer producer AIM3D showcased a brand new era of pellet 3D printing know-how on the occasion, introducing its Voxelfill slicer plug-in with Create it REAL and a Excessive-Efficiency Improve for the ExAM 255/510 methods. Voxelfill delivered a serious energy acquire, slicing PETG-GF anisotropy from 56.7% to 13.5%, whereas Enter Shaping and Extruder Strain Management improved accuracy, edge definition, and print speeds.

The corporate additionally broadened its footprint with new U.S. installations, underscoring the effectivity of its CEM course of, which affords excessive throughput and as much as 96% decrease materials prices than filament-based methods.

One other German equipment producer KraussMaffei debuted its new PowerPrint Flex modular robotic large-format additive manufacturing (LFAM) system designed for scalable industrial manufacturing at Formnext.

The system blends a Comau N-170 robotic, a 2,500 × 2,000 mm heated print mattress, and the high-output printCore 35-25 extruder, which processes supplies akin to PEEK, PEI, and carbon-filled polymers at as much as 70 kg/h. Guided by Siemens Sinumerik One, the open structure helps hybrid additive-subtractive workflows, enabling quicker iteration and mold-free manufacturing of huge, light-weight, high-accuracy parts.

Israeli 3D printing firm XJet expanded entry to its NanoParticle Jetting (NPJ) know-how with the launch of the Carmel Professional, a compact, lower-cost system debuting on the tradeshow. Designed for SMEs, analysis labs, and premium jewellery makers, the machine delivers the precision, density, and floor end of bigger Carmel platforms at 60–70 % decrease funding.

Its powderless ink-jetting course of helps 4 materials channels for true multi-material metallic and ceramic 3D printing, whereas automation options, quick job changeovers, and inside ink recirculation streamline operation and cut back waste for high-value purposes.

Chief Government Officer Man Zimmerman described the launch as “a major milestone in democratizing entry to industrial, powderless, and protected metallic and ceramic additive manufacturing.”

Becoming a member of the 3D printer launches can be Austrian engineering agency and OEM Incus GmbH unveiled the Hammer Pro25, a metallic 3D printer engineered to bridge prototyping and true industrial manufacturing. The printer pairs a big automated platform with the corporate’s Lithography-based Steel Manufacturing to keep up 25 µm decision at scale, boosted by twin scrolling projectors for expanded construct space with out high quality loss.

Having as much as 980 cm³/hr throughput, lights-out automation, and Ra 2 µm post-sinter surfaces, it allows secure, high-volume manufacturing whereas lowering price per half and accelerating time to market. Gerald Mitteramskogler, CEO of Incus, stated, “With the Hammer Pro25, we allow our prospects to completely leverage the benefits of additive manufacturing – particularly in industries with brief growth cycles.”

Elsewhere, Belgian Molten Steel Deposition (MMD) know-how supplier ValCUN detailed new efficiency knowledge for its MMD course of whereas additionally introducing REMUS 1.0, a next-generation printhead constructed to industrialize wire-fed aluminium AM. The MMD course of melts customary aluminium wire contained in the printhead, slicing vitality use by as much as eightfold and enabling ready-to-use elements with out debinding, sintering, or build-plate removing.

REMUS 1.0 extends this functionality with high-throughput wire feeding, localized preheating, oxidation cleansing, and non-planar movement, supporting industrial alloys within the 6xxx and 7xxx collection. Collectively, the method and {hardware} goal decrease price, deployable aluminium 3D printing for purposes in cooling, automotive constructions, and area restore.

French industrial silicone 3D printer producer Lynxter unveiled two new immersion-based modules, NEST-GEL and NEST-POWDER, for its S300X – LIQ21 | LIQ11 silicone 3D printer on the tradeshow. The plug-and-play modules use reusable gel or water-soluble powder to completely assist elements throughout fabrication, enabling ultrathin, advanced geometries, lowered post-processing, and multi-part 3D nesting.

NEST-GEL targets high-precision industrial silicone elements with a 20–80 °C heated mattress, whereas NEST-POWDER, developed with 3Deus Dynamics, helps delicate, medical-grade parts. The system affords a 280 × 220 × 100 mm construct quantity, 0.23-1.04 mm nozzles, and 50 µm–1 mm layer heights with single or twin impartial extrusion.

Probably the most participating launches got here from Chinese language 3D printer producer Bambu Lab debuting the H2C, a desktop 3D printer designed to advance multi-material printing for skilled customers. Its centerpiece is the brand new Vortek Hotend Change system, a contactless six-hotend array that permits as much as seven supplies per job, expandable to 24 with AMS, with out purge waste.

Hotends keep in mind previous filament assignments, automation handles calibration and compatibility checks, and a four-camera suite screens the printing course of. Beneath the hood, an inductive 8-second heat-up, PMSM servo extruder, sub-50 µm movement accuracy, and a 65°C actively heated chamber make the H2C a tightly engineered platform constructed for velocity, reliability, and severe experimentation.

Additionally, German 3D printer producer EOS launched the M4 ONYX, a metallic LPBF 3D printer engineered for greater throughput and extra secure, cost-efficient manufacturing. The machine’s 450 × 450 × 400 mm construct space is powered by six 400 W lasers that, in accordance with EOS, ship 50% quicker output and as much as 30% decrease half prices. A FLX variant with 4 1 kW beam-shaping lasers targets even larger velocity and geometric flexibility.

Stability upgrades akin to refined gasoline movement, lively thermal administration, and Sensible Fusion controls work alongside Siemens-driven Construct+ software program and MES/ERP APIs to streamline qualification and minimize QA workloads. With greater than 90% powder reuse, automated closed-loop powder dealing with, and sub-30-minute job swaps, the M4 ONYX arrives as a tightly built-in, production-scale platform for superior metallic purposes.

EOS CEO Marie Langer stated the platform displays the corporate’s “dedication to empowering producers worldwide,” crediting the launch to the dedication and experience of its international engineering groups.

Pennsylvania-based 3D printer producer Xact Steel arrived on the tradeshow to spotlight a measured enlargement of its metallic 3D printing lineup, led by the XM200G µHD. The brand new system introduces a 25 µm laser spot and assist for five–15 µm powders, extending the XM200G platform into purposes that demand finer options; its 140 × 140 × 150 mm construct space may also be prolonged to 290 mm in Z.

Two new powders joined the ecosystem as effectively, with Sandvik’s Osprey MAR 55 device metal and Equispheres’ NExP-1 non-reactive aluminum broadening materials choices. Xact Steel additionally reported continued growth of the XM300G, a mid-size machine with as much as 4 1 kW lasers and a 300 × 300 × 400 mm construct quantity meant for higher-capacity workflows.

TRUMPF Additive Manufacturing, now rebranded as ATLIX, debuted two new metallic 3D printers aimed toward strengthening its industrial manufacturing portfolio. The TruPrint 5000 leads the lineup, providing a 500 × 500 × 400 mm construct quantity, 4 1 kW lasers with automated multilaser alignment, adjustable 80–200 µm spots, and double-side recoating for secure, steady operation.

The up to date TruPrint 3000 introduces a 30% bigger construct space at 300 × 300 × 400 mm and a twin 700 W laser setup for medium-format elements. Each methods combine with the newest TruTops Print software program, which reduces file measurement and accelerates knowledge switch for quicker construct preparation.

“In continuity with our legacy as TRUMPF Additive Manufacturing, our improvements all have one goal: make additive manufacturing a really industrial actuality,” stated Marino Ferrarese, Head of Gross sales and Advertising and marketing at ATLIX.

INTAMSYS launched the FUNMAT PRO 310 APOLLO, describing it as an industrial polymer 3D printer constructed for PAEK-class supplies and steady manufacturing. The system combines a 450°C nozzle, 100°C chamber, and 160°C construct plate with an IDEX structure able to speeds as much as 500 mm/s, with PAEK workflows optimized at 200 mm/s.

A sealed 3 kg drying chamber helps week-long runs of hygroscopic supplies, whereas mesh leveling, dual-extruder auto-calibration, and onboard monitoring streamline operation. Powered by INTAMSUITE NEO and INTAMQuality, the APOLLO targets robust, heat-resistant end-use parts with production-grade consistency.

British extrusion methods producer E3D introduced its new ObXiDian 500, a serious replace to its abrasion-resistant nozzle line. The brand new collection delivers a minimum of 5× the damage resistance of the unique ObXidian and is now rated for 500°C, opening the door to high-temperature polymers.

A redesigned high-flow insert splits filament into 4 channels, boosting thermal switch and elevating movement charges by as much as 70% for quicker, stronger prints. E3D additionally launched a Excessive Stream ObXiDian 500 Full HotEnd for Bambu Lab methods, giving H2D, H2C, H2S, and P2S customers a drop-in path to greater throughput and sturdy, steady efficiency.

In different information, Colibrium Additive expanded its metallic 3D printing portfolio with the industrial debut of the M Line 4 x 1 kW system, a higher-power evolution of its earlier 4 x 400 W platform. The machine delivers a 500 × 500 × 400 mm construct space and 4 1 kW IPG lasers, giving producers the flexibility to print crucial options with tight precision whereas accelerating manufacturing in much less delicate areas.

Its modular LPS-MHS structure retains laser processing and materials dealing with separate, permitting parallel workflows that minimize downtime and streamline powder operations. Appropriate with CoCr and Ni718, the system retains full parameter continuity with earlier M Line instruments, all managed by the WRX3 suite with OPC/UA knowledge entry.

Massive-format 3D printer producer BigRep confirmed how far large-format FFF can stretch, unveiling the ONE.5 with a one-cubic-meter construct quantity and a brand new PEX2 extruder delivering 40% greater movement and Twin Mode functionality.

The absolutely automated VIIO 250 added continuous-production options akin to twin 350°C SMX extruders and an Infinity Field for hands-free spool adjustments, whereas the DRYCON system launched 180°C drying and annealing in a dual-chamber setup. A pellet-extrusion challenge with Large Dimension and new PIR-based rPLA and rPETG filaments rounded out a portfolio aimed toward quicker, extra environment friendly large-scale manufacturing.

Czech based mostly 3D printer producer Prusa Analysis and Swedish extrusion specialist Bondtech launched the Bondtech INDX, a purpose-built multi-material toolhead improve for the Prusa CORE One 3D printer. The system facilities on the INDX Sensible Toolhead, which makes use of induction heating, contactless temperature sensing, and a self-adjusting dual-extrusion feeder to change supplies inside seconds.

Light-weight Skinny Passive Instruments, mounted at 35 mm spacing, enable as much as eight nozzles on a single head with minimal purge waste. Joint growth throughout firmware, {hardware}, and PrusaSlicer ensures the INDX features as a totally built-in, high-speed multi-material resolution for superior desktop customers.

Farsoon Applied sciences launched the HT601P-2 large-format polymer PBF system constructed for high-volume, steady manufacturing. The machine affords a 600 × 600 × 600 mm construct space and two 100 W CO₂ lasers, enabling as much as 12 kg of elements per day at 12% nesting density.

Digital galvo scanners, multi-zone thermal management inside ±3°C, and non-obligatory IR monitoring assist uniform vitality supply and fewer than 5% mechanical variation throughout the platform. An interchangeable build-cartridge system streamlines job turnover, whereas 220°C chamber functionality expands materials choices to PA6, PA11, PA12, PBT, and TPU for demanding industrial purposes.

Elsewhere, TPM3D offered a brand new era of skilled SLS options on the tradeshow, introducing the CF200 SLS 3D printer and PPS200 powder processing station.

Designed as a closed-loop ecosystem, the system improves effectivity, half high quality, and course of reliability by optimized optics, thermal management, and automatic calibration. The launch underscores TPM3D’s objective of decreasing boundaries to industrial SLS adoption whereas sustaining precision, scalability, and lowered whole price of possession.

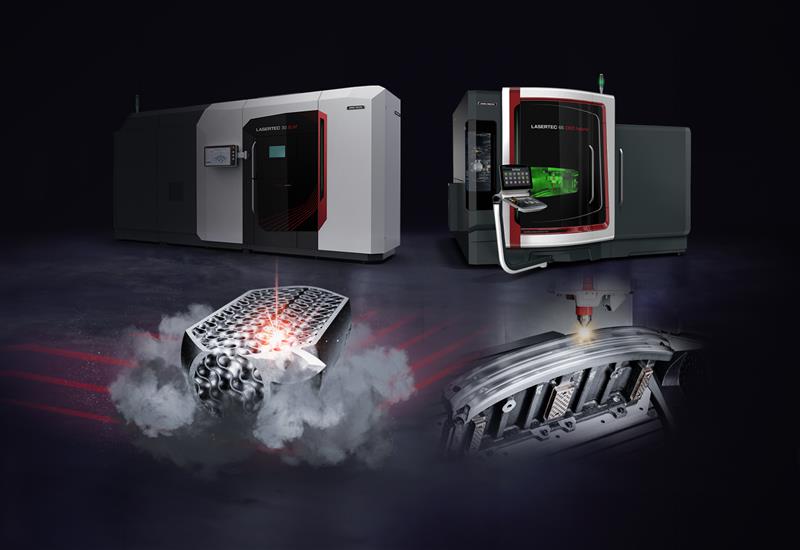

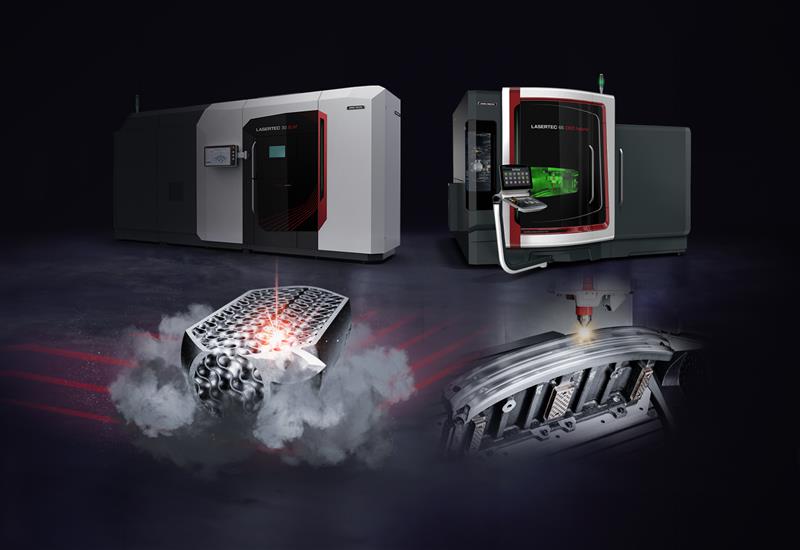

Lastly, main CNC machine device producer DMG MORI put the highlight on industrial-scale additive manufacturing, showcasing advances in each hybrid and PBF applied sciences. Its LASERTEC DED hybrid machines mix milling, turning, grinding, preheating, laser deposition welding, and 3D scanning in a single setup, permitting seamless shifts between additive and subtractive steps for advanced or multi-material elements.

Blue-laser functionality expands processing to reflective metals, whereas built-in scanning allows non-contact inspection. In PBF, the LASERTEC 30 SLM third Technology introduces an interchangeable construct container, exterior plate prep, and lively Z-axis compensation, all supported by as much as 4 overlapping lasers and CELOS X with easyAM for steady, carefully monitored manufacturing.

New supplies broaden industrial AM capabilities

Subsequent up, Zetamix ceramic and metallic filaments producer Nanoe and nuclear supplies producer Orano used the tradeshow to exhibit their new growth on anti-corrosion supplies for additive manufacturing, introducing two customized Zetamix filaments: 304L stainless-steel and Monel 400, engineered for nuclear purposes. Developed for traditional FFF methods and paired with Nanoe’s sintering furnaces, the filaments assist speedy prototyping and small-scale manufacturing in high-corrosion environments akin to nuclear gasoline electrolysis.

Leveraging Nanoe’s “Zetamix on demand” program and experience in metals and ceramics, the partnership goals to enhance turnaround instances, broaden design potentialities, and speed up feasibility research for specialised alloys in nuclear analysis and upkeep.

Polish metallic 3D printing firm AMAZEMET offered its new AI-controlled rePOWDER atomization platform at Formnext, demonstrating absolutely autonomous metal-powder manufacturing for supplies R&D. The system’s machine-vision mannequin evaluates melt-pool habits each 120 ms and routinely adjusts torch place, plasma energy, and feed fee to keep up optimum circumstances and enhance PSD consistency.

A redesigned management cupboard within the newest model provides edge-AI computing, a high-speed PLC, and built-in gas-recirculation security. In benchmark assessments with Ti-6Al-4V, AMAZEMET achieved 0.5 kg/h output throughout 4 hours of unattended operation, with deliberate extensions to assist alloys akin to NiTi and C-103 and longer autonomous runtimes.

From the 3D printing giants, 3D printer OEM Stratasys showcased new industrial AM capabilities below its “Get Critical About Additive” theme, emphasizing licensed supplies and repeatable manufacturing. The producer displayed practically 200 elements throughout its FDM, PolyJet, SAF, P3, and stereolithography platforms, highlighting new supplies akin to ToughONE WhiteS and P3 Silicone 25A for high-strength, versatile, and biocompatible purposes.

Reside demonstrations of Digital Anatomy with Addion GmbH illustrated 3D printed anatomical eye fashions for coaching in eyelid surgical procedure, underscoring Stratasys’ focus towards dependable, end-use polymer manufacturing. Furthermore, highlights included the CoatReady mode for smoother ULTEM 9085 elements on the F900, quicker carbon-fiber builds on the Fortus 450mc with the Nylon 12CF T40 Tip, expanded sustainable TrueRefill supplies, and new accuracy and thermal-control options for SAF and SLA methods. The corporate additionally showcased high-temperature P3 tooling supplies and new equipment designed to streamline post-processing.

And US-based supplies producer Aether launched its RapidPrint filament line at Formnext 2025, positioning it as a quicker path to high-performance polymer elements. The primary materials, RapidPrint PA6 CF10 ABX, is a PA6 bolstered with 10% carbon fiber and tuned for top soften movement, secure bonding, and speeds between 50 and 250 mm/s.

Demonstrations on the AON3D’s Hylo 3D printer confirmed how its soften habits allows as much as five-times quicker deposition with out sacrificing energy, a sensible acquire for protection, aerospace, and drone applications that want speedy iteration and end-use sturdiness.

Supplies producer Cubic Ink launched a set of recent photopolymers aimed toward extra specialised purposes, amongst them Cubic Ink Mould 3100 VP for breakable audiology molds and Cubic Ink Dental 3000 VP for detailed thermoforming instruments, alongside a heat-resistant, high-impact resin designed for orthotics.

The supplies producer additionally broadened its rapid-tooling capabilities by a Print & Inject workflow developed with SK Industriemodell, opening the door to injection molding with polymers akin to PA66 GF, PPS, and PEEK. In parallel, Cubic Ink scaled UV-curing resin manufacturing within the US with ALTANA, a transfer meant to strengthen provide for industrial customers.

3D printing supplies firm Kexcelled expanded its supplies portfolio with new sustainable and high-performance supplies. Highlights included the Eco-Aesthetic PLA Filament Sequence made with 10% recycled espresso, tea, or bamboo waste, combining pure aesthetics with a refined aroma throughout printing.

The corporate additionally launched new elastomer supplies together with K9 PEBA 90A and two K8 TPU variants, addressing skilled wants for flexibility, sturdiness, and refined floor high quality.

New software program platforms strengthen digital AM workflows

Advancing the software program focus, Stratasys launched the iAM Market, an impartial, hardware-agnostic platform that consolidates polymer AM supplies, engineering companies, and authorized merchandise. Designed as a centralized hub, it brings collectively choices from manufacturers akin to iSQUARED, Ahead AM, and Nexa3D to simplify sourcing throughout numerous {hardware} methods.

The platform marks a strategic enlargement past proprietary ecosystems, supporting broader materials compatibility, streamlined procurement, and elevated provide resilience. Guests explored the brand new ecosystem and its integration with Stratasys applied sciences at Corridor 11.1, Sales space C11.

“The launch of iAM Market is a daring step ahead in our supplies technique,” stated Yoav Zeif, CEO of Stratasys. “It offers all producers with a broad portfolio of quality-certified supplies, machines, and experience, enabling quicker innovation and stronger provide resilience.

Moreover, Caracol unveiled the latest Eidos Manufacturing Software program Suite, including AI-driven sensing, expanded AM and post-processing steps, and extra autonomous end-to-end workflows. Eidos Builder now connects slicing, simulation, scanning, and milling, whereas Eidos Nexus introduces AI Management for adaptive machine operation.

Demonstrations featured the Heron AM and Vipra AM platforms and large-format elements produced with companions akin to Alstom, NP Aerospace, UK’s Digital Manufacturing Middle, JOME, and CPC Group, together with a 120-hour printed catamaran created with V2 Boats.

Formnext additionally noticed Iceland-based software program firm Euler formally launch its real-time AI defect-detection software program for LPBF and SLS, following a profitable paid pilot program. The corporate showcased hardware-free monitoring that analyzes stay digital camera knowledge and has demonstrated a 77% discount in failed-build downtime.

Co-led by Frumtak Ventures and Kvanted, its latest €2 million seed spherical is accelerating commercialization, patent exercise, and ecosystem integrations. On the occasion, Euler additionally introduced new partnerships with Autodesk and Scanlab.

Know-how and consulting firm Certified AM exhibited its new QamX software program, a modular system that permits streamlining AM qualification by integrating compliance, threat evaluation, and provider traceability right into a single auditable workflow. The platform unifies documentation for requirements akin to ISO 9001, AS9100, and FDA 21 CFR Half 820, lowering qualification cycles by as much as twentyfold.

Modules together with QamX Cert, QamX SCM, QamX QMS, and QamX RISK synchronize knowledge throughout groups, automating SOPs, pFMEA analyses, and provider administration to streamline validation for aerospace, medical, vitality, and semiconductor manufacturing environments.

Belgian 3D printing service bureau Materialise rolled out a trio of recent CO-AM platforms, Skilled, NPI, and Enterprise, every powered by the newly launched CO-AM Brix and CO-AM Construct Platform. The upgrades convey sharper automation, tighter traceability, and simpler qualification into AM workflows, from high-mix manufacturing to full multi-site execution.

A next-generation Construct Processor framework provides open, modular integration for OEM instruments and customized methods. It’s a clear sign that Materialise is constant to advance interoperable, manufacturing-first AM software program, lastly giving customers workflow management that feels industrial fairly than experimental.

Luxembourg-based 3D scanner developer Artec 3D launched Artec Studio Lite, a streamlined tackle its skilled 3D data-processing platform. The software program leans on AI-powered photogrammetry to show images or movies into correct 3D fashions, eradicating the necessity for devoted scanning {hardware}.

A lot of the core toolset from Artec Studio Professional stays, together with mesh modifying, measurement evaluation, multi-camera merging, and artifact cleanup, whereas automated workflows and scale-bar assist simplify reconstruction and real-world sizing. Designed to deal with difficult surfaces and restricted imagery, Studio Lite affords designers, educators, and small groups a extra accessible route into dependable 3D seize and mannequin preparation.

Nikon SLM Options partnered with Swedish visualization and analytics software program firm Interspectral to ship an built-in quality-assurance workflow that ties AM Explorer immediately into Nikon SLM Options machines. Exhibited at Formnext, the setup merges machine logs, sensor knowledge, simulations, and CT scans right into a single digital thread, utilizing AI analytics to identify deviations and hint root causes.

When paired with Nikon’s open-architecture, multi-laser methods, the platform allows real-time course of benchmarking and stability validation. Early adopters akin to GKN Aerospace report improved traceability and lowered variability, positioning the combination as a sensible device for scaling AM into licensed manufacturing.

“AM Explorer enhances our manufacturing course of by automating advanced workflows and making certain strong high quality assurance,” stated Martin Thordén, Vice President at GKN Aerospace Sweden. “It helps our objective of scaling AM manufacturing whereas sustaining stringent aerospace business requirements.”

UK-based metallic 3D printing firm Wayland Additive introduced that its Calibur3 NeuBeam system is now built-in into the Autodesk Fusion machine library, giving customers a unified design-to-print workflow for electron beam PBF. Engineers can deal with design edits, assist methods, construct preparation, and slicing immediately in Fusion with parameters tuned for NeuBeam, eliminating the fragmented software program stacks that usually gradual PBF-EB adoption.

The brand new machine profile runs on each Home windows and macOS, marking the primary time Mac customers can full full Calibur3 construct setups. Wayland says the collaboration boosts productiveness and lowers boundaries for aerospace, medical, and industrial metallic AM workflows.

Montreal-based AON3D launched a physics-driven G-code post-processing module that accelerates material-extrusion 3D printing by as much as 54% by modeling every polymer’s rheology and thermal habits. The system predicts warmth buildup and dissipation inside an element and dynamically adjusts deposition velocity to keep away from soften fracture, deformation, or weakened welds, enabling quicker printing with out compromising high quality.

Inside assessments minimize a 24-hour ABS construct to 11 hours. Built-in into the Hylo and Foundation platform, the device pairs high-temperature {hardware} with automated parameter tuning and in-situ defect detection for extra environment friendly, lower-overhead manufacturing.

Berlin-based software program developer trinckle showcased its Additive App Suite, a set of design automation instruments for additive manufacturing. The platform allows engineers to create advanced, print-ready designs in minutes with out superior CAD abilities.

By way of guided, application-driven workflows aligned with actual industrial processes, the suite connects DfAM ideas with manufacturing must speed up design cycles, cut back prices, and scale additive manufacturing extra effectively.

Strategic acquisitions and partnerships reshape the AM panorama

Adopted by new enterprise offers, cleansing and floor ending methods producer DyeMansion’s presence at Formnext 2025 highlighted the profitable integration of Munich firm ASM and its VX1 vapor smoothing system into the corporate’s Print-to-Product workflow. Constructing on their 2024 gross sales partnership, the acquisition expands DyeMansion’s portfolio to completely cowl entry-level, mid-range, and industrial polymer surface-finishing wants.

Already adopted by 50+ customers, the compact, sustainable-solvent VX1 now sits alongside the Powerfuse S Guide and Computerized methods, giving DyeMansion the business’s most complete vapor-smoothing lineup. The stay VX1 demonstrations on the present offered guests with a transparent view of the expanded capabilities now out there.

AltForm, the newly rebranded successor to Prima Additive, launched its expanded laser-manufacturing portfolio below Sodick’s possession. The corporate premiered its Print 300 and Print 400 Sequence PBF methods, including modular construct chambers, stabilized gasoline movement, refined thermal management, and coordinated multi-laser operation, all tied into an upgraded powder-handling ecosystem.

A Print Genius 300 ran stay with automated chamber extraction and a low-maintenance passivation-based filtration module. AltForm additionally rolled out a unified AI-driven software program suite for monitoring, fleet administration, and traceability, and demonstrated its modular ZENIT robotic cell for Wire DED and interchangeable laser processes.

Steel 3D printer producer Nikon SLM Options and Additive Assurance unveiled a serious monitoring breakthrough at Formnext, integrating AMiRIS Inside into the NXG platform to ship the primary near-infrared optical tomography system able to observing all 12 lasers concurrently in a production-scale metallic 3D printer.

The system offers full-field, real-time melt-pool and layer evaluation, enhancing consistency, traceability, and confidence for giant multi-laser builds. In response to the corporate, the combination is a step towards certifiable serial manufacturing in aerospace, protection, and vitality purposes.

HP Additive Manufacturing Options outlined a broad push towards extra scalable industrial 3D printing, introducing new supplies, ecosystem partnerships, and upcoming filament methods alongside up to date MJF workflows. A key spotlight was HP 3D HR PA 11 Gen2, a polymer providing as much as 80% powder reuse and as much as 40% decrease variable half prices, supporting HP’s goal of lowering total price per half by 20%.

On the metallic facet, OptiPowder Ni718 is now certified for the Steel Jet S100 by partnerships with Continuum Powders and INDO-MIM, whereas M247LC is advancing with Continuum Powders and TECNALIA, and expanded copper purposes are being developed with GKN Powder Metallurgy. HP additionally previewed its IF 600HT and IF 1000 XL filament printers, signaling an expanded position in high-temperature and large-format polymer manufacturing.

One other partnership was introduced by Stratasys consists of the 3D printer OEM working with Tritone Applied sciences to fold metallic and ceramic manufacturing into its broader AM providing, giving prospects a clearer path to multi-material manufacturing with out juggling a number of distributors. As a part of the deal, Stratasys has taken a minority stake in Tritone and arrange a phased industrial settlement to align gross sales channels and reseller assist.

The partnership facilities on Tritone’s MoldJet powder-free course of for high-throughput, industrial-grade metallic and ceramic elements, identified for its dense output, fast materials changeovers, and skill to supply various geometries in a single batch.

Ceramic AM enters true serial manufacturing throughout medical and industrial sectors

On the medical entrance, Austrian ceramic 3D printing specialist Lithoz showcased how ceramic AM has absolutely transitioned into dependable, industrial-scale manufacturing. Throughout aerospace, semiconductors, medical gadgets, and premium client items, the corporate confirmed how its LCM know-how and international Ceramic 3D Manufacturing unit community are enabling actual serial manufacturing.

Highlights included the CeraFab System S320 operating a full plate of 46 turbine-blade casting cores, reflecting work at Safran Plane Engines, alongside Plasway-designed ALD rings produced by Alumina Programs and high-volume gasoline injectors from Bosch Superior Ceramics.

Including to that, ATZ patient-specific earmoulds created by OC GmbH and CADdent, and the award-winning Thales VORO cartridge from HiFiction AG and Steinbach AG, bolstered how ceramic AM now delivers scalable precision with each useful and aesthetic influence.

Johannes Homa, Lithoz CEO stated, “This concerted give attention to premiering real-world parts efficiently scaled to industrial degree on Lithoz CeraFab printers is our manifesto for serial manufacturing in ceramic 3D printing.”

AM’s certification infrastructure expands

At Formnext 2025, amsight and Certified AM offered their new whitepaper, High quality Administration and Certification in Additive Manufacturing, providing an in depth technical information to establishing reproducible and compliant AM workflows. The publication outlines key requirements akin to ISO/ASTM 52920, 52930, and 52954, together with step-by-step certification strategies masking threat evaluation, course of qualification, and audit readiness.

It additionally highlights how QMS, MES, and knowledge analytics instruments allow full traceability and course of stability. The whitepaper showcases amsight’s data-driven software program and Certified AM’s digital qualification framework as sensible pathways for scalable, licensed AM manufacturing. Guests might receive the printed version on the joint sales space.

“Certification in additive manufacturing is now not a formality — it’s a strategic enabler of reproducibility and industrial scalability,” stated Dr.-Ing. Tim Wischeropp, Co-Founder and CEO of amsight.

ASTM Worldwide’s Additive Manufacturing Middle of Excellence (AM CoE) outlined seven coordinated initiatives aimed toward serving to business scale AM with larger confidence. In the US, new initiatives with America Makes and companions together with Boeing, Lockheed Martin, NASA, and Baker Hughes give attention to quicker, lower-cost qualification by improved in-situ monitoring and non-destructive inspection.

In the UK, the £38 million DECSAM program provides an aerospace dimension, with Airbus and a broad consortium working to spice up LPBF productiveness and promote round materials use. Certification efforts have additionally expanded, with new accreditations in Germany, Latvia, and the Philippines, whereas a partnership with Additive Middle B.V. brings ASTM’s coaching and requirements for semiconductor manufacturing.

Automation takes heart stage in subsequent era submit processing

Additive Manufacturing Applied sciences (AMT) closed out a robust yr by introducing two main upgrades to its automated ending methods portfolio. The PostPro UP removes guide powder-bed unpacking by direct build-plate loading and full DMS workflow integration.

Alongside UP, the PostPro SF2X is a compact unit that doubles processing quantity whereas utilizing PostPro AI to optimize vapor movement, temperature, and cycle instances all the way down to 30-45 minutes. Each methods had been demonstrated on the Formnext occasion, highlighting AMT’s push towards absolutely automated, high-throughput post-processing.

On one other observe, DyeMansion showcased six workflow-focused developments aimed toward decreasing TCO and enhancing effectivity throughout its Print-to-Product chain. Key updates embrace the newly built-in ASM VX1 vapor-smoothing system with the most important chamber in its class, the L-RR Cartridge that reduces black-dyeing prices by as much as 70%, and a redesigned Powerfuse S Loading Information with built-in solvent restoration.

Extra upgrades embrace the Powerfuse Basket Max for 20% greater capability and Powershot X IoT Integration for full runtime and efficiency monitoring. The brand new DyeMansion Campus platform helps operator coaching and standardized manufacturing information.

“The longer term belongs to those that create worth, not simply options. Our focus is on improvements that push additive manufacturing towards larger scalability, competitiveness, and sustainability,” stated Felix Ewald, CEO and Co-Founding father of DyeMansion.

Having secured 50 patents for post-processing, PostProcess Applied sciences launched the DEMI X 5000, positioning it as a high-throughput resin-removal system for more and more giant and sophisticated SLA workflows. Constructing on the DEMI 4100, the brand new system tackles full-size SLA builds in 10 minutes or much less, boosted by variable-speed pumps that generate multi-vortex agitation and an adjustable tilt mechanism for hard-to-reach geometries.

A non-flammable chemistry guarantees as much as 75% decrease waste-disposal prices, whereas a totally enclosed chamber, improved ergonomics, and automatic lifting improve security. Supported by the AUTOMAT3D platform, the DEMI X 5000 brings repeatability and production-floor polish to scaled SLA operations.

In the meantime, post-processing methods producer Solukon introduced a strongly automation-focused message, introducing a particular SFM-AT800-S configuration that hyperlinks automated half transport, depowdering, and a robotic ending stage developed with Grenzebach and Yaskawa. The system demonstrated how a number of post-processing steps can function as a coordinated workflow fairly than remoted guide duties.

Additionally on show was the SFM-AT350-E, the corporate’s most generally deployed unit, which employs ultrasonic excitation to clear powder from delicate geometries and handles elements as much as 100 kg, together with construct plates from giant metallic AM methods such because the EOS M 400 and Nikon SLM 500. Solukon capped the week with a Tenth-anniversary sales space promotion for guests.

Axtra3D rolls out a tightly linked SLA manufacturing platform

Shifting on to platforms, high-speed SLA printer producer Axtra3D unveiled Axtra Workflow, a totally built-in AM manufacturing platform that hyperlinks construct preparation, printing, post-processing, inspection, and traceability into one validated course of. Pairing HPS printing with automated cleansing, drying, and UV plus thermal curing by Axtra.Wash and Axtra.Remedy, the ecosystem reduces variability and streamlines throughput.

Axtra.Perception provides real-time analytics by amassing knowledge from greater than 155 sensors for layer-level monitoring, predictive upkeep, and compliance-ready documentation. Upgrades to the LumiaX1 v25 and Quantity v25 software program additional refine sensing, movement management, slicing, and fleet administration, enhancing repeatability and qualification readiness for industrial and controlled purposes.

AI designed hypersonic {hardware} exhibits the potential of huge scale metallic AM

Dubai-based engineering firm LEAP 71 and Farsoon Applied sciences showcased an AI-designed, metallic 3D printed hypersonic precooler at Formnext, a 1.5-meter-tall part created utilizing the Noyron computational engineering platform and produced on the large-format FS811M-U-8 system.

The challenge demonstrates how AI-driven design and industrial-scale LPBF can understand advanced, high-performance geometries at unprecedented peak. Developed as a know-how demonstrator for air-breathing, single-stage-to-orbit ideas, the precooler highlights new potentialities for reusable, runway-launched hypersonic spacecraft.

“By combining Computational Engineering with large-scale metallic Additive Manufacturing, we now have a shot at overcoming a number of the most elementary boundaries to realizing that imaginative and prescient,” stated Lin Kayser, Co-Founding father of LEAP 71.

Fraunhofer IWU unveils next-generation WEAM for built-in electrical performance

Fraunhofer Institute for Machine Instruments and Forming Know-how’s (IWU) newest Wire Encapsulating Additive Manufacturing system, proven on the tradeshow, allows direct embedding {of electrical} features utilizing customary alloy wires as an alternative of conductive pastes or inks. The method prints homogeneous wires with managed diameters and layouts, permitting tuned electrical efficiency, excessive mechanical energy, and dependable sensing or energy supply.

A constantly rotating printhead deposits conductors onto advanced shapes, supporting purposes akin to de-icing radomes, stretchable TPU circuit boards, PFAS-free high-temperature wiring, and drone housings with built-in coils. The result’s a flexible, recyclable pathway for multifunctional aerospace, automotive, and robotics parts.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential buyers, and prospects with the 3D Printing Trade Begin-up of 12 months competitors.

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or comply with us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits Formnext 2025 at Messe Frankfurt, guests arriving on the tradeshow. Photograph by Michael Petch.