Researchers on the Université de Lorraine in France have examined methods to simplify plastic recycling by decreasing the necessity for pre-sorting, serving to to advance Distributed Recycling Additive Manufacturing (DRAM) as a framework for extra localized and round manufacturing methods.

This method is critical as a result of sorting combined plastic waste stays one of the expensive and energy-intensive phases in recycling, typically limiting materials restoration charges and financial viability. Enabling direct processing of combined streams might decrease operational boundaries, scale back waste, and make decentralized recycling fashions extra sensible.

The research was performed in collaboration with the ERPI and LRGP laboratories at Université de Lorraine, alongside the Division of Electrical and Laptop Engineering at Western College in Canada.

To evaluate feasibility, the crew labored with recycled polyethylene terephthalate (rPET) and recycled high-density polyethylene (rHDPE) obtained from discarded water bottles. They in contrast typical processing strategies with fused granular fabrication (FGF) 3D printing, mixing rPET and rHDPE at a 90/10 weight ratio. The target was to find out whether or not instantly printing combined recycled plastics might ship mechanical efficiency corresponding to that achieved by means of conventional extrusion and injection molding routes.

Processing Strategies and Mechanical Efficiency

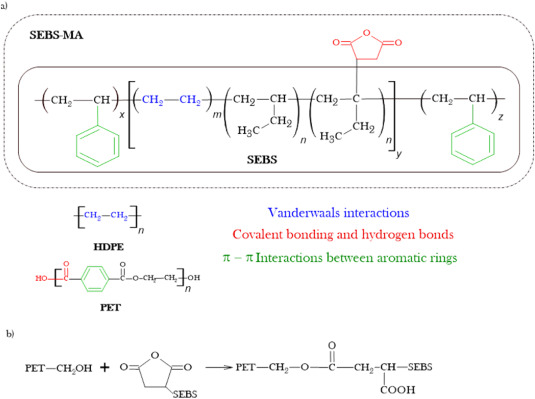

To boost compatibility between combined polymers, the research integrated three styrene-based compatibilizers at 10% by weight: two non-reactive grades (G1650 and G1652) and a reactive maleated SEBS, cirKular+ C1010. In response to lead researcher Cécile Nouvel of Université de Lorraine’s CNRS laboratory, the analysis sought to deal with “the excessive prices and inherent inefficiencies of typical processes” by minimizing sorting steps in recycling streams.

Mechanical testing revealed notable variations between manufacturing strategies. Components produced by means of twin-screw extrusion and injection molding demonstrated roughly 50% greater tensile energy and 34% larger influence resistance in comparison with these fabricated through FGF 3D printing. Conventionally processed samples had been totally dense, whereas printed elements contained inner voids ensuing from the layer-by-layer deposition course of.

Nevertheless, the additively manufactured samples exhibited benefits in different areas. They confirmed diminished thermal degradation and displayed extra structured crystalline group at elevated temperatures.

Compatibilizer addition improved elongation at break by round 40% in conventionally processed supplies. Rheological evaluation indicated that G1652 lowered the soften stream index by roughly 10%, whereas G1650 diminished it by 47%, each reflecting elevated viscosity. In distinction, the reactive C1010 barely elevated soften stream index by 6%.

Processing Limitations and Future Instructions

For the additive trials, researchers employed a modified Gigabot XL system geared up with a single-screw extruder and a residence time of two.2 minutes. The crew noticed that “a single mixing level typically leads to non-uniform shear distribution, which may hinder the efficient breakdown of polymer domains,” highlighting a limitation in present large-format FGF setups.

Primarily based on these findings, the researchers prompt integrating twin-screw or planetary curler extrusion methods instantly into 3D printers to realize extra uniform mixing and improved materials efficiency.

Round AM Expands — However Feedstock Stays Managed

Circularity initiatives in additive manufacturing have grown, however they principally depend on managed, homogeneous waste streams. Constructing on this trajectory, the Université de Lorraine research explores instantly printing combined post-consumer plastics (PET and HDPE) with out prior sorting, tackling a key bottleneck in distributed recycling.

Different initiatives illustrate the present panorama: College of Colorado Boulder, engineers launched a campus program to gather and remanufacture PLA print waste into reusable filament, displaying how localized recycling can scale back landfill disposal in academic environments.

Pellet-based methods corresponding to WASP’s CUBO HDP course of shredded plastics instantly on-site, enabling decentralized reuse with out counting on filament provide chains. The printer tolerates some variability in particle dimension, however assured efficiency is simply achieved with an inventory of examined polymers, that means the feedstock remains to be successfully managed.

In business, Filamentive’s recycling service demonstrates an analogous sample: post-consumer filament is collected, reprocessed, and returned as high-quality feedstock, however the scheme is simply out there for PLA waste.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential traders, and prospects with the 3D Printing Trade Begin-up of Yr competitors.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Linkedin.

Featured picture exhibits A) Chemical construction of SEBS, SEBS-MA, PET and HDPE with potential interplay b) response of the terminal hydroxyl group of PET with maleic anhydride of the SEBS. Picture through Université de Lorraine.