Researchers at Virginia Tech have developed a way to create shape-memory ceramic supplies that may be manufactured at scale utilizing 3D printing know-how. Affiliate professor Dangle Yu, together with Ph.D. pupil Donnie Erb and postdoctoral researcher Nikhil Gotawala, used additive friction stir deposition to embed ceramic particles into steel matrices. Their analysis was printed in Supplies Science and Engineering R: Experiences.

The workforce’s method addresses a long-standing problem in supplies science. Form-memory ceramics can change their inside construction underneath stress or warmth and return to their unique kind, however they’ve traditionally been too brittle for large-scale manufacturing. Earlier analysis confirmed these supplies labored at microscale, however scaling up for structural functions proved troublesome because the supplies would break aside.

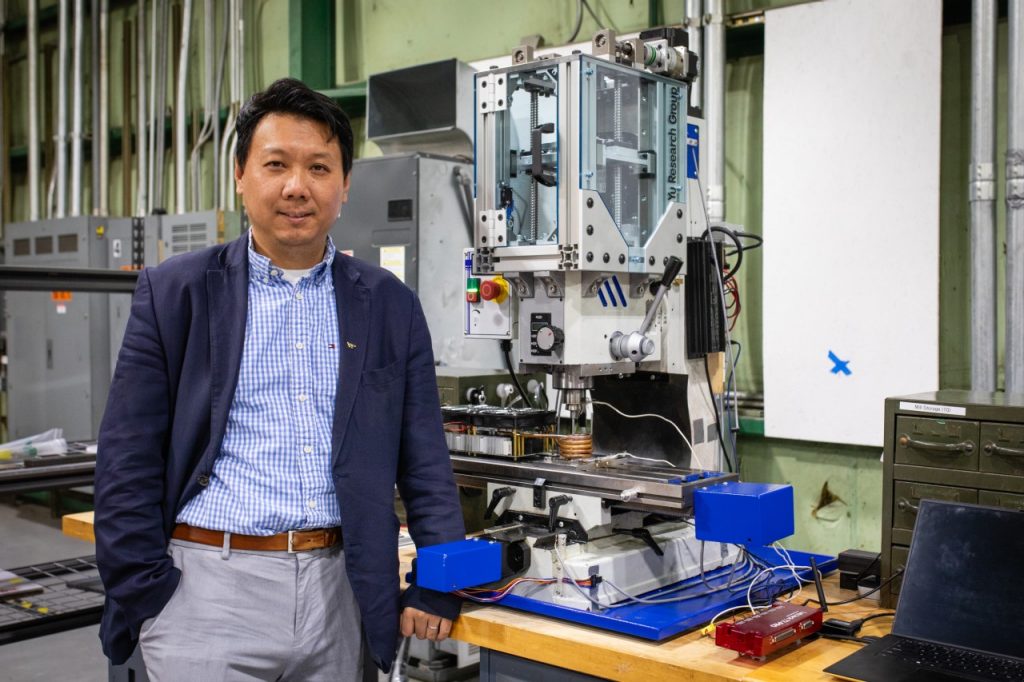

The brand new approach embeds tiny shape-memory ceramic particles into steel utilizing a course of Yu in comparison with “placing chocolate chips into cookie dough.” The additive friction stir deposition machine spins the supplies quick sufficient to meld them collectively with out melting, making a composite that maintains the ceramic’s shape-memory properties whereas gaining the steel’s structural integrity. “This composite can afford pressure, bending, compression, and take in vitality by way of stress-induced martensitic transformation,” mentioned Yu.

The ensuing materials might have functions in protection programs, aerospace, infrastructure, and sporting tools. Potential makes use of embody vibration damping in golf membership shafts or impression absorption in protection functions. “For the primary time, this analysis creates bulk shape-memory ceramic–steel matrix composites utilizing a scalable, solid-state 3D-printing course of,” Yu mentioned. The analysis was supported by the Nationwide Science Basis and the U.S. Military Analysis Laboratory.

Supply: information.vt.edu