Could 2025 bolstered a central theme in additive manufacturing: institutionalization. Not like months centered on new {hardware} or breakthrough supplies, Could’s dominant tales revolved round who controls the stack, who certifies components, and the place long-term capital is being deployed. Consequently, additive manufacturing more and more seems with rising frequency as a vital industrial infrastructure, embedded in nationwide methods and company operations.

Industrial Coverage, Capital, and Lengthy-Time period Dedication

The month highlighted multi-year investments, signaling that governments and Tier-1 industrial gamers are committing capital to AM as strategic capability. As an example, Australia doubled down on its nationwide additive manufacturing centre funding, establishing the $271 million NAMC as a high-value hub for 3D printing throughout aerospace, protection, and medical functions. The middle helps manufacturing processes, productiveness, and workforce coaching, reflecting a strategic view of AM.

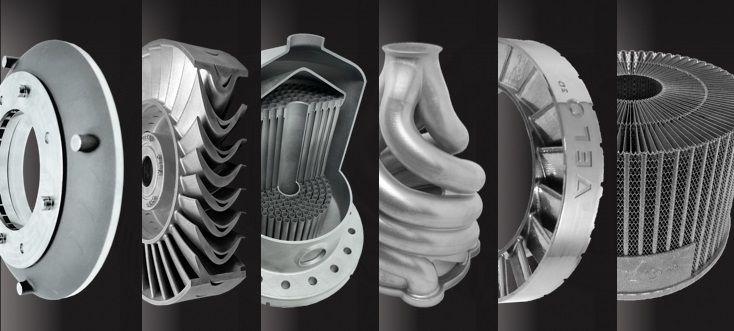

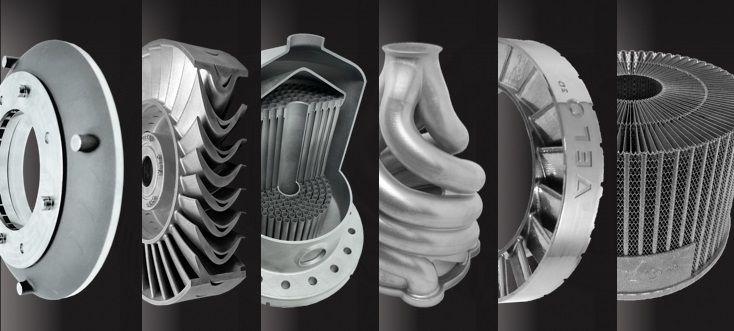

Equally, Swiss supplier Oerlikon dedicated CHF 40 million to its Campus Reichhold innovation and manufacturing hub, consolidating three current Swiss websites right into a single facility that integrates analysis, engineering, and manufacturing. Oerlikon additive manufacturing funding manufacturing hub, highlights the corporate’s dedication to advancing AM capabilities.

Each initiatives illustrate that AM is not handled as experimental. Australia’s NAMC displays industrial coverage and long-term planning, whereas Oerlikon’s funding indicators private-sector confidence in AM, embedding the expertise in nationwide and company stability sheets.

Consolidation and Management of the Industrial Stack

Could 2025 highlighted a pronounced development in AM: incumbents are consolidating management over vital components of the economic stack. Past possession, this consists of metrology, supplies, and software program infrastructure, that are key elements for standardization, qualification, and operational reliability.

A number of acquisitions illustrate this shift. AMETEK FARO acquisition of additive manufacturing metrology strengthened AMETEK’s management over precision measurement and inspection capabilities, vital for qualification and reliability in AM. Stratasys strengthened its industrial place via the Stratasys Ahead AM supplies acquisition, enhancing its capabilities in Selective Absorption Fusion (SAF) and Digital Gentle Processing (DLP) applied sciences.

Equally, KEYENCE CADENAS acquisition 3D engineering software program offers KEYENCE the chance to advance the event of 3Dfindit, CADENAS’ engineering platform, and improve its digital catalog capabilities for international customers. In the meantime, Sodick Prima Additive acquisition metallic 3D printing allowed Sodick to increase its attain into superior metallic AM.

These strikes should not about development hype; they’re about threat administration, margin safety, and tightening oversight of the design-to-production pipeline. By bringing supplies IP, metrology, and software program below their management, machine-tool and automation giants are absorbing AM into established industrial frameworks fairly than being disrupted by it. The broader implication is evident: consolidation reinforces requirements and course of governance.

Market Stress and the Prosumer Actuality Verify

Whereas the month underscored consolidation and capital deployment by industrial gamers, not all segments of AM are stabilizing. The prosumer {and professional} desktop market, specifically, continues to indicate structural pressure.

A transparent sign got here from the BCN3D chapter within the prosumer 3D printer market. Fairly than a narrative of outright failure, this episode displays persistent pressures on mid-range desktop producers: pricing constraints, restricted entry to capital, and competitors from each higher-end industrial machines and low-cost client units.

The prosumer phase’s fragility supplies a counterpoint to the sturdy investments and acquisitions seen elsewhere in Could. Though BCN3D later stabilized, the month’s developments underscore the continued vulnerability of mid-range prosumer choices in contrast with the broader, industrial-scale adoption of AM.

Governance, Self-discipline, and the Publish-Merger Period

May highlighted a shift from growth to operational self-discipline amongst AM consolidators, with Nano Dimension restructuring technique FY 2025 serving as a number one instance. Following a interval of aggressive acquisitions and SPAC-era development, Nano Dimension is consolidating its portfolio, aligning enterprise models, and establishing operational controls to make sure stability and predictability throughout its product strains.

Insights from our Nano Dimension CBO interview underscore this evolution. Julien Lederman describes the corporate’s present focus as embedding disciplined processes, streamlining workflows, and aligning assets with strategic priorities, steps that replicate a broader post-SPAC reckoning within the business.

This evolution underscores that, in 2025, structured integration and rigorous governance are as important to AM as technological innovation, transferring the sector away from speculation-driven development towards institutionalized administration practices.

Qualification, Requirements, and Belief Infrastructure

In Could, the main focus in AM continued to broaden past the 3D printers themselves. The business’s most important constraints had been inspection, certification, and requirements, highlighting a broader transfer towards constructing belief infrastructure because the core enabler of commercial adoption.

Notable developments embody America Makes QTIME additive manufacturing inspection to advance AM capabilities in LPBF and DED processes, Singapore aerospace additive manufacturing customary, and ASML certified additive manufacturing provide chain. Certification efforts additionally prolonged into maritime and power, with Titomic DNV certification for maritime additive manufacturing, whereas Lithoz achieved ISO 13485 for medical machine 3D printing.

Collectively, these initiatives sign a maturing ecosystem. Requirements and verification frameworks are spreading past aerospace into semiconductors, maritime, power, and medical ceramics, reflecting that inspection and high quality assurance are actually structural challenges fairly than non permanent hurdles.

On this context, AM more and more progresses on the “velocity of belief,” with adoption depending on demonstrable reliability, repeatability, and regulatory compliance.

Protection as Demand-Facet Pull, Not Experimentation

May bolstered that AM is not a instrument for experimentation inside protection; it has develop into an built-in element of manufacturing and provide chains. US Air Pressure additive manufacturing program chosen Elementum 3D as one of many awardees for the $46 billion Enterprise-Huge Agile Acquisition Contract (EWAAC), underscoring this transition by embedding superior supplies and reactive AM into armament modernization packages.

Collaborations throughout the protection sector additional spotlight this development. Nikon SLM Options, ATI, and Bechtel Plant Equipment deployed NXG 600E metallic printers to supply high-performance elements for hypersonic propulsion in additive manufacturing. In the meantime, Velo3D Amaero provide settlement metallic additive manufacturing expanded the corporate’s footprint, whereas Velo3D protection manufacturing Ohio Ordnance Works optimized 3D printed weapon elements via a strategic collaboration.

These initiatives exemplify programmatic adoption fairly than pilot-scale trials. Protection procurement now drives industrial pull-through, with propulsion and supplies ecosystems forming round certified suppliers.

AI Strikes into Operations, Not Simply Design

In Could, AI in additive manufacturing shifted from producing design novelty to operational integration. The partnership between Palantir Applied sciences and Divergent Applied sciences exemplifies this evolution, with AI-powered on-demand manufacturing Palantir, enabling customers of Palantir to entry Divergent’s on-demand elements, bettering flexibility and accelerating manufacturing timelines.

This improvement demonstrates AI’s position in industrializing complexity. As a substitute of changing engineers, it identifies manufacturing bottlenecks, optimizes assets, and allows just-in-time manufacturing. It additionally reinforces broader consolidation and governance tendencies, with decision-making, information administration, and operational oversight more and more coordinated via software-driven methods.

Regulation of Recordsdata, Not Simply Elements

The month highlighted a rising give attention to digital governance in AM. Manhattan District Lawyer Alvin Bragg, Jr., along with New York legislators, launched the New York 3D printed gun blueprint legislation (S227A/A1777A), which criminalizes the net sharing of 3D printed firearm designs. By concentrating on digital information fairly than simply bodily components, the laws units a precedent for platform legal responsibility and the administration of open-source CAD.

The implications prolong past firearms. As AM ecosystems develop into more and more digital, management over design information is rising as a vital lever of operational, regulatory, and institutional oversight, reinforcing Could’s broader shift towards digital governance as a basis for requirements, certification, and strategic industrial management.

Could’s Legacy for the Remainder of 2025

Could 2025 marked a turning level in AM, signaling the sector’s shift from innovation-driven hype to structured industrialization. The month demonstrated that long-term capital commitments, rigorous requirements, and operational self-discipline are actually the first drivers of progress.

Investments by governments and Tier-1 industrial gamers, together with the embedding of AM into protection provide chains, highlighted strategic intent and resilience. In the meantime, AI’s integration into manufacturing and provide choices illustrated that digital instruments are operationalizing complexity fairly than merely producing novelty.

By the shut of Could, it was clear that AM’s trajectory is outlined much less by new applied sciences or particular person innovators and extra by who controls, certifies, and governs, signaling 2025 as a turning level towards industrial maturity and structural consolidation.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential traders, and prospects with the 3D Printing Trade Begin-up of 12 months competitors.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or comply with us on Linkedin.

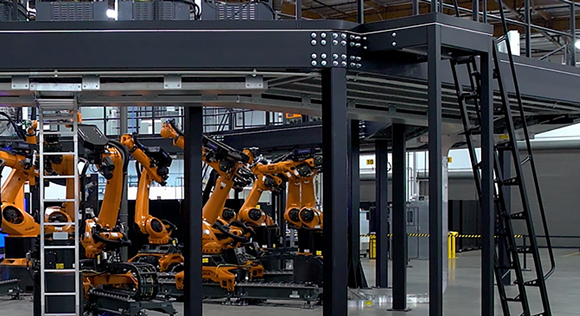

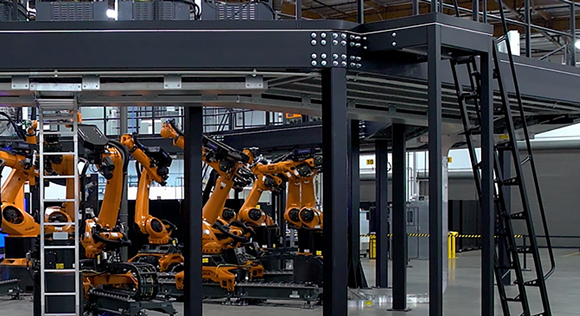

Featured picture exhibits Ceremony of the brand new heart for thermal spray coatings and methods and laser-based applied sciences at Campus Reichhold. Photograph through Oerlikon.