Organisations throughout numerous industries face vital information administration challenges. Receiving, changing, and deciphering an ever-growing quantity of information, whereas making certain that the suitable folks have entry to the right information and assembly compliance necessities, is extremely complicated.

For QC leads and manufacturing engineers, it’s important to keep up high-quality requirements and resolve manufacturing points rapidly. Expertise should imperatively be stored updated—counting on outdated practices corresponding to transferring recordsdata by way of community drives or USB sticks is just not solely time-consuming and inefficient, but additionally vulnerable to errors.

Information administration software program options like PolyWorks|DataLoop™ present:

- Actual-time entry to inspection outcomes

- Accelerated decision-making

- Simplified collaboration

- Streamlined workflows

Frédéric Hébert, Vice President of Merchandise and Innovation for the Collaborative Suite, states, “By digitizing inspection undertaking administration, PolyWorks|DataLoop delivers optimum collaboration, safety, and traceability—eliminating rework and selling greatest practices throughout metrology groups and suppliers.”

GE Home equipment: driving smarter data-driven choices with PolyWorks|DataLoop

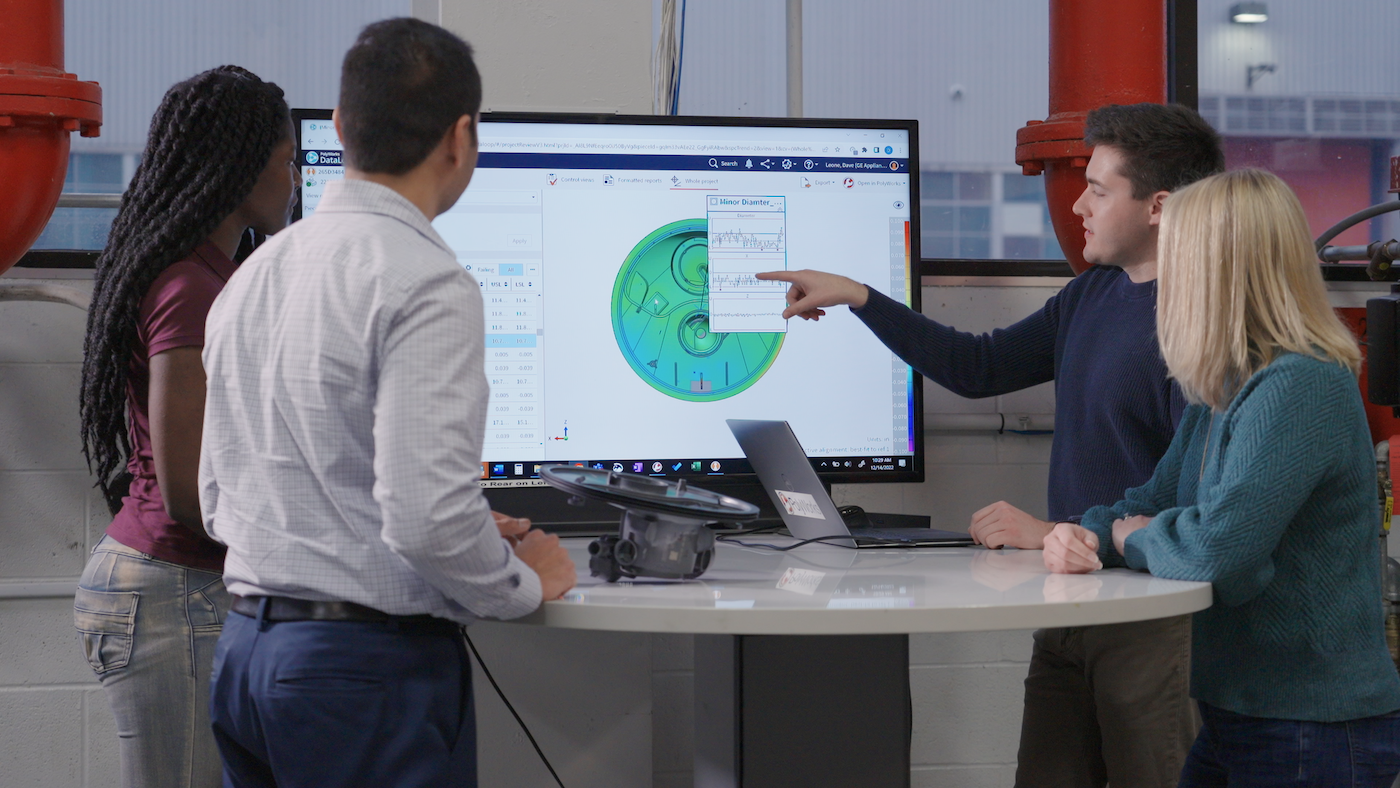

Dealing with the complexities of equipment manufacturing, GE Home equipment adopted PolyWorks|DataLoop to make higher data-driven choices, increase high quality and productiveness, and handle 3D measurement information extra effectively, making certain the suitable folks promptly obtain the right information.

Based in 1907, GE Home equipment makes a speciality of heating and cooking merchandise. The corporate is thought for improvements corresponding to the primary self-cleaning oven and over-the-range microwave.

Managing a number of product strains and a whole lot of elements per product is exceptionally difficult, and the corporate wanted to boost each high quality and productiveness. To attain this, GE Home equipment concluded that standardizing software program throughout a number of measuring gadgets, aggregating 3D metrology information, and delivering that information to engineers was essential. As Dave Leone, Senior Director of Engineering and Dimensional Management, says, “All of the 3D information on the earth is just not that priceless if engineers can’t get their palms on it.”

GE Home equipment turned to PolyWorks|DataLoop to beat their challenges. The answer handles huge volumes of information produced by a number of measuring sources and makes such information available to engineers and decision-makers.

PolyWorks|DataLoop permits groups to:

- Measure elements seamlessly

- Evaluation outcomes rapidly

- Simply troubleshoot points

- Regulate manufacturing processes concurrently

Hébert particulars how PolyWorks|DataLoop maintains high quality requirements whereas permitting a number of folks to entry the identical information, explaining, “PolyWorks|DataLoop offers instruments that make greatest practices simple to implement throughout all inspection initiatives. As an example, reusable piece and undertaking templates for inspections, together with strong metadata administration, guarantee consistency and traceability. Lifecycle management instruments assure that the suitable folks have entry to the suitable information on the proper time. As well as, PolyWorks|DataLoop provides monitoring and alerts that safeguard the integrity of metrology information.”

Permitting a number of people to entry information can pose a safety danger. Relating to the answer’s versatile safety coverage, Hébert specifies, “Permission profiles could be outlined for the big variety of information managed inside PolyWorks|DataLoop, making certain every consumer accesses solely what they want. These controls leverage state-of-the-art authentication applied sciences that comply with greatest practices in cybersecurity governance.”

Key options of PolyWorks|DataLoop:

- Supplies centralized storage for 3D measurement information

- Tailors the {hardware} setup to your small business wants

- Automates file and folder administration

- Maximizes information switch pace

- Optimizes disk house utilization

RT: Why ought to QC leads and engineers put money into PolyWorks|DataLoop over different options?

FH: QC leads and manufacturing engineers ought to select PolyWorks|DataLoop as a result of it’s the key enabler of the digital metrology lab. By digitizing inspection undertaking administration, PolyWorks|DataLoop ensures optimum collaboration, safety, and traceability—eliminating rework and selling greatest practices throughout metrology groups and suppliers. The PolyWorks|DataLoop Net Interface is intuitive and requires no deployment, making adoption seamless. Lastly, its openness actually units it aside: with strong APIs, connectors like these we developed for Microsoft Excel and Energy BI, and PLM integrations, PolyWorks|DataLoop delivers a versatile information administration system that integrates easily into fashionable digital ecosystems.

RT: In the event you might identify one overarching profit that QC leads and engineers obtain from PolyWorks|DataLoop, what wouldn’t it be?

FH: Empowerment by means of a real digital thread for 3D measurement processes—remodeling uncooked metrology information into actionable perception. With PolyWorks|DataLoop, QC leads and manufacturing engineers acquire safe, seamless entry to the suitable information on the proper time, collaborate effortlessly throughout groups and {hardware}, and unlock the complete potential of their measurement ecosystem to drive high quality, effectivity, and innovation.