Formnext 2025 in Germany brings one other wave of commercial 3D printing launches, and QIDI is utilizing the occasion to introduce its new flagship system: the QIDI Max4. Positioned as the biggest print-size possibility amongst consumer-grade enclosed printers, the Max4 goals to deal with a long-standing problem on this phase: the “issue in reaching each giant print measurement and excessive precision.”

In keeping with QIDI, the Max4 combines a considerably expanded construct quantity with movement management, thermal administration and automation options designed for skilled customers who wish to produce giant components with out compromising on element or reliability.

Giant construct quantity with uniform thermal management

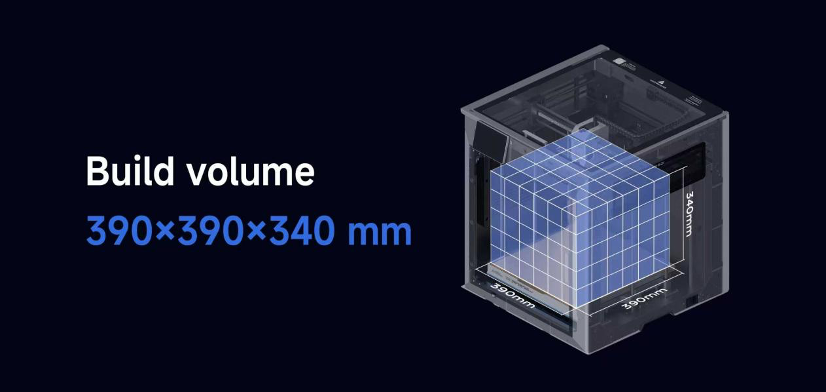

The QIDI Max collection has constructed its status on large-format and versatile printing, and the Max4 pushes that additional. The system presents a construct quantity of 390 × 390 × 340 mm, which QIDI states is 55% bigger than the earlier Max3. This measurement targets functions equivalent to giant industrial elements, intricate molds and customised prototypes, the place single-piece builds can scale back meeting steps and potential weak factors.

To assist this envelope, the Max4 makes use of a 390 × 390 mm heated mattress with a full-surface silicone thermal layer and densely distributed heating wires. QIDI highlights this as one of the uniform heating designs in its class. A high-efficiency insulation cotton layer beneath the mattress additional stabilizes temperature throughout the floor. Collectively, these parts are meant to enhance first-layer adhesion and maintain large-format prints steady, with decreased threat of warping throughout the construct plate.

Excessive-flow extrusion and managed printing setting

On the extrusion aspect, QIDI equips the Max4 with a brand new high-flow hot-end rated at 40 mm³/s. That is designed to allow considerably quicker print speeds, significantly helpful when filling a big construct quantity, and to assist scale back total manufacturing cycles for sizable components.

The nozzle is made out of hardened metal, which broadens materials compatibility past fundamental filaments. QIDI lists assist for traditional PLA and ABS, alongside some industrial supplies equivalent to abrasive carbon fiber–bolstered nylon. This mix of upper move and wear-resistant {hardware} is geared toward customers who want throughput and composite functionality on one machine.

Thermal management extends past the mattress and hot-end. The Max4 debuts QIDI’s self-developed Lively Toolhead Cooling System, known as the “Polar Cooler.” This method directs cooled air straight onto the extruder and filament path to enhance warmth dissipation and assist stop clogs throughout demanding jobs.

In parallel, the printer makes use of a second-generation Lively Chamber Heating system that may keep an inner temperature of as much as 65°C with optimized air circulation. QIDI positions this as a key enabler for high-temperature supplies, naming ABS, ABS-CF and PC as examples that profit from a heated setting and steady airflow.

Movement system upgrades for stability and precision

To enhance print stability and half high quality at velocity, the QIDI Max4 introduces a brand new closed-loop motor system on the XY axes. As an alternative of working open-loop, the motors work with a closed-loop encoder that screens errors and compensates for deviations on the fly.

QIDI outlines three primary advantages of this method. First, larger stability: the system goals to stop step loss and scale back layer misalignment over lengthy or advanced jobs. Second, improved accuracy: decreased torque ripple is meant to decrease floor artifacts equivalent to seen rippling or cogging. Third, enhanced effectivity: the closed-loop motors are designed to run cooler and quieter at excessive speeds, which may reduce thermal influence on inner elements and contribute to an extended operational lifespan.

Z-axis efficiency receives comparable consideration. The Max4 makes use of 2 mm lead screws mixed with an anti-backlash nut to take away vertical play and keep constant positioning. This configuration is geared toward smoother Z movement and better Z-axis accuracy, with the purpose of minimizing layer strains and enhancing floor element, particularly on tall components that occupy a lot of the printer’s construct top.

Past the core movement elements, QIDI provides a number of supporting options: a brand new auto-leveling sensor, industrial-grade linear rails and customized 1.5GT belts. Collectively, these parts are meant to ship smoother, extra exact movement management whereas enhancing the machine’s sturdiness underneath frequent use.

AI monitoring, interface updates and QIDI BOX integration

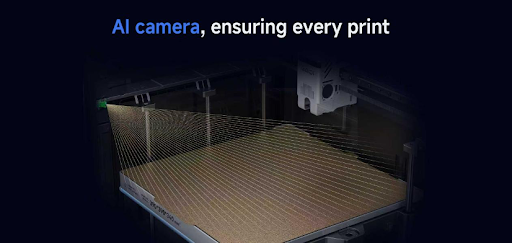

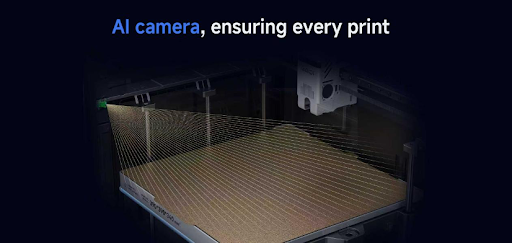

On the usability and automation aspect, the QIDI Max4 introduces an AI recognition system constructed round a high-performance processor. Utilizing a high-definition digital camera, the printer constantly screens the print in actual time and analyzes picture knowledge alongside print instructions. When it detects points equivalent to “spaghetti” failures or issues in assist buildings, the system can robotically pause the print and ship an alert. That is designed to chop down on wasted materials and scale back the necessity for fixed handbook supervision on longer jobs.

The consumer interface has been up to date as nicely. A brand new giant display screen and redesigned UI goal to supply smoother fingertip management and a extra trendy interactive expertise, from setup to monitoring.

For multi-color and multi-material workflows, the Max4 might be paired with the QIDI BOX. This accent extends the printer’s capabilities by supporting as much as 16 colours concurrently and offering filament drying at temperatures as much as 65℃. Together with the printer’s high-temperature chamber and hardened nozzle, this setup is positioned to be used circumstances starting from multi-color creative fashions to engineering-grade composite components and complicated, multi-material objects.

Market positioning, availability and gross sales plans

With its bigger construct quantity, bolstered movement system, high-flow hotend, chamber heating and AI-driven monitoring, the QIDI Max4 is introduced as the brand new flagship in QIDI’s lineup. The corporate frames the system as a aggressive entry within the large-format enclosed desktop phase, concentrating on skilled customers who need greater effectivity, steady efficiency and an more and more automated consumer expertise in a single machine.

QIDI states that the Max4 is now accessible for world pre-order by means of its official channels.

In keeping with the Qidi official web site, BFCM gross sales will launch as we speak on November 18th, and clients can look ahead to upcoming promotions there.

By combining high-temperature functionality, precision-focused movement management and expanded multi-material choices by way of the QIDI BOX, the Max4 positions itself as a large-format platform for each purposeful and inventive work. Its launch at Formnext 2025 underlines QIDI’s intention to develop its position within the skilled 3D printing area and to compete extra straight within the large-format class.