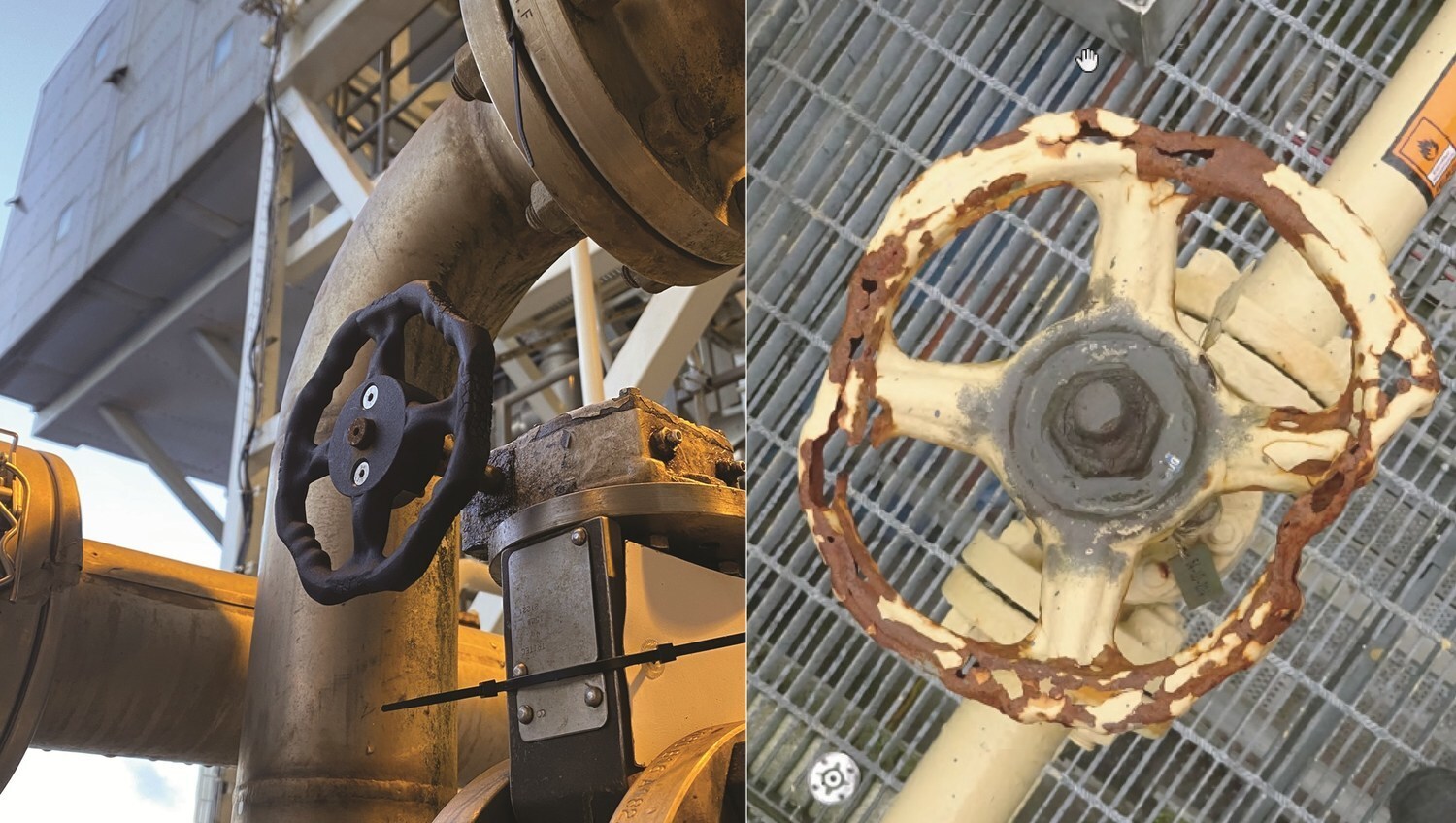

Assembrix Ltd., HP, Sparely, and Korall Engineering AS have accomplished a sequence of safe distant additive manufacturing operations throughout a number of international websites to supply licensed spare elements for the oil and fuel business. The collaboration produced polymer valve handwheels designed for handbook operation of non-critical valves on ships and offshore platforms. Elements have been printed at a number of HP accomplice websites utilizing HP Multi Jet Fusion methods built-in with the Assembrix software program platform.

The printed elements have been created from HP 3D Excessive Reusability PA12 supplies, which Korall Engineering is qualifying in collaboration with DNV. These characterize the primary additive manufacturing polymers to be certified for offshore functions. The ensuing designs provide corrosion resistance and sturdiness in harsh environments whereas decreasing materials use, weight, and manufacturing lead instances.

Every construct course of was encrypted, remotely managed, and monitored in actual time to validate repeatability, traceability, and safety. The Assembrix platform supplies encryption and management for each stage of printing manufacturing to guard delicate construct information. “The sequence demonstrated that an identical elements may be produced throughout areas with out compromising integrity, proving that safe, scalable distributed manufacturing is now an industrial actuality,” said Lior Polak, CEO of Assembrix.

The method goals to cut back lead instances from months to days whereas chopping logistics prices and stock necessities for oil and fuel operators. Localized manufacturing additionally reduces transport emissions and materials waste in comparison with conventional manufacturing strategies. “This collaboration proves that safe digital manufacturing may be each scalable and sensible for the oil and fuel sector,” commented Bernhard van Riessen, CEO of Sparely.

The companions place this work as establishing a benchmark for connecting design, certification, and manufacturing in a safe international community. “By combining Assembrix’s safe digital workflow, HP’s manufacturing consistency, Sparely’s international manufacturing community, and our certified household of specialised designs, we demonstrated that important elements can now be produced safely and domestically, prepared for licensed discipline use,” mentioned Bruno Maffei, CEO of Korall Engineering.