In additive manufacturing, the printing step typically will get the highlight, but it surely’s the quieter, remaining stage of post-processing that may make or break effectivity. For a lot of organizations, this step stays handbook, slowing throughput, introducing security dangers, and creating bottlenecks that stand in the way in which of scalable manufacturing.

Increasingly more, firms are turning to automated options from PostProcess Applied sciences to unravel this downside, and the good points are measurable.

Highlighted under are a few real-world buyer tales demonstrating the identical level: automating post-processing with PostProcess Applied sciences isn’t just about comfort. It’s about enabling additive manufacturing to operate as a really scalable manufacturing know-how. Whatever the effectivity good points from sooner 3D printers or higher supplies, one can solely go to date earlier than post-processing turns into the limiting issue.

Breaking the bottleneck

In Wisconsin, LED lighting producer J.W. Speaker found simply how a lot time and labor handbook FDM assist removing might eat. Operators spent hours dealing with delicate geometries, and components typically required in a single day drying earlier than they may transfer on.

Bigger builds generally needed to be break up into a number of sections merely to suit the method, slowing supply even additional. By introducing the PostProcess BASE resolution alongside a Stratasys F3300 3D printer, the corporate lowered turnaround from 1 week to only 9 hours and saved an estimated $60K–$75K annually.

“With our previous machine, we must put the components in an oven in a single day to dry out. Now, we’ve got the components cleaned and able to be delivered in simply a few hours,” stated Michael Speaker, Lead Additive Manufacturing Specialist.

The identical sort of bottleneck appeared at Stratasys Direct Manufacturing’s Tucson SLA and P3 facility, although right here the difficulty was resin cleansing. Their reliance on isopropyl alcohol (IPA) baths and hand instruments made cleansing inconsistent, hazardous, and sluggish.

IPA rapidly saturated, leaving cheesy surfaces that led to remodel or rejected components, whereas fixed operator consideration delayed machine turnaround. By adopting PostProcess DEMI 4100 and DEMI 830 methods, Stratasys Direct reduce total processing time by about 60%, with cleansing cycles now averaging simply 10 minutes.

As Director of Operations, Sean Schoonmaker put it, “We’ve been capable of scale back whole post-processing time.” The Director defined, “For instance, a job that took us 120 minutes to post-process now solely takes 45 minutes.”

In France, dental manufacturing heart Ninety! confronted a special however equally urgent problem. With Stratasys J5 DentaJet 3D printers able to producing a whole lot of fashions a day, handbook PolyJet assist removing had turn into unsustainable. Operators struggled with fragile geometries, batch sizes remained small, and assembly 24-48 hour supply expectations grew more and more troublesome.

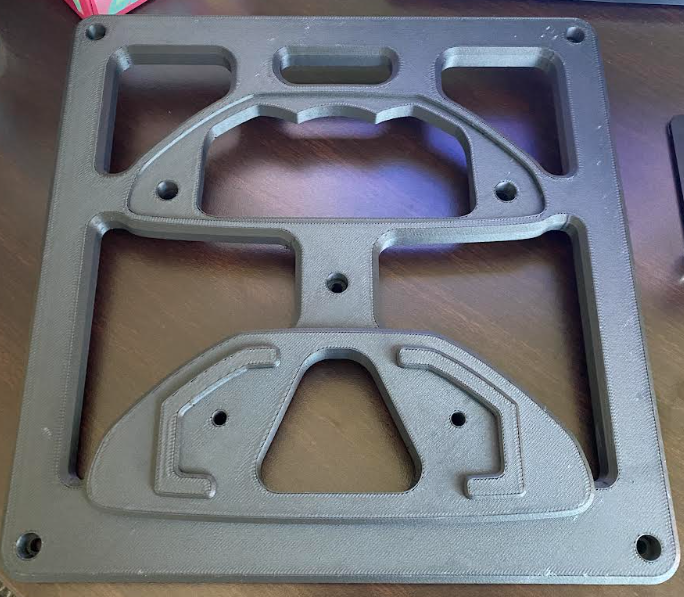

The PostProcess DEMI X 520 resolution remodeled this workflow, scaling capability to 200 components in a single cycle and making it potential to disclose 100% of the printing high quality offered by Stratasys, in comparison with simply 70-80% with handbook cleansing.

Co-Director Olivier Mangot defined, “I’m now not depending on an operator. With this resolution, I can clear 20 instances extra components than earlier than and get extremely high-quality outcomes.” He added, “Once I calculate my ROI on the finish of the yr, I’ve elevated my productiveness and saved cash. And, I lowered my ecological affect whereas enhancing my staff’ working situations.”

Wish to assist map the long run?

To seize the place the trade stands right now, PostProcess notes, “we’re launching our post-printing survey to seize the evolving panorama and higher perceive trade wants.” Responses will inform the 2025 Submit-Processing Developments Report, offering a data-driven view of how organizations are addressing this important step and the place the trade is headed.

In case you work with additive manufacturing, your enter is important. Fill out the survey right now and assist form the way forward for post-processing.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or observe us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits operator utilizing the PostProcess DEMI X 520 system. Picture by way of PostProcess Applied sciences.