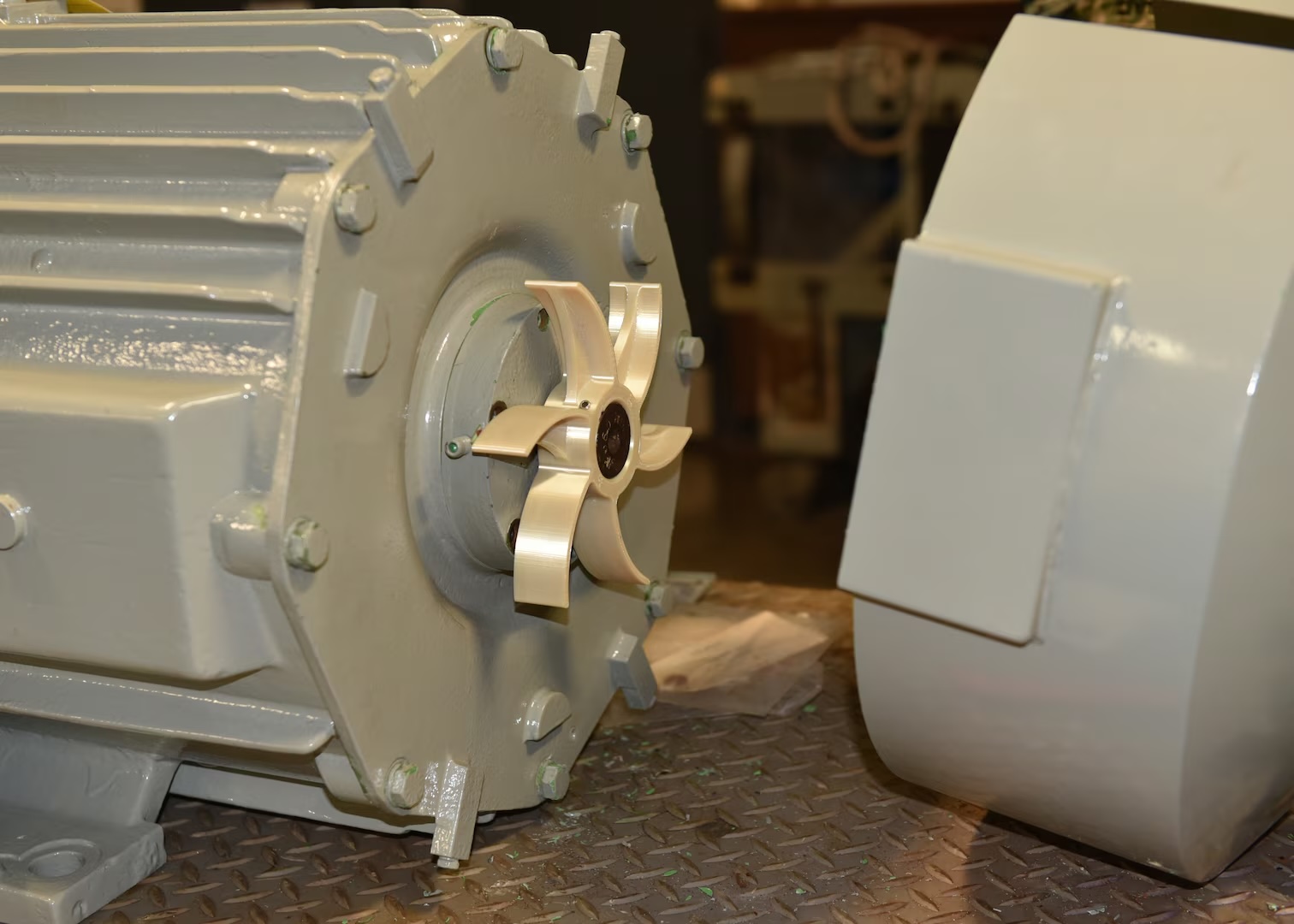

The Southeast Regional Upkeep Middle (SERMC) has efficiently used 3D printing to fabricate a substitute cooling rotor for an Arleigh Burke-class guided missile destroyer’s chilled water pump. The six-blade part isn’t offered individually by way of the Navy provide system, usually requiring the acquisition of a whole new pump unit.

The SERMC crew developed 4 prototypes over two weeks utilizing reverse engineering strategies. They started with a low-cost polymer model of the unique aluminum half earlier than coordinating with Fleet Readiness Middle Southeast Detachment Mayport to pick the ultimate materials. The completed part was manufactured utilizing an aerospace-grade thermoplastic recognized for energy, warmth resistance, and flame retardancy.

The associated fee distinction between 3D printing and standard substitute proved vital. A prototype blade price $17.63 to supply, whereas the ultimate blade price $131.21. Changing the whole motor by way of conventional procurement would have price $316,544.16.

“Sailors at SERMC are at all times on the lookout for new purposes for 3D printing to broaden our capabilities and save time, assets, and cash,” mentioned Capt. Kiah Rahming, SERMC’s commanding officer. “This effort is a testomony to the ingenuity and drive of our crew.” The printed part has been operationally examined, licensed, and put in aboard a destroyer. These cooling pump rotors are used throughout all ship varieties within the Navy fleet.

Supply: navsea.navy.mil