Velo3D, a U.S.-based steel 3D printer producer, has entered right into a five-year unique provide settlement with Amaero, Australian-based steel AM specialist, projected to generate roughly $22 million in income. Underneath the phrases, Amaero will function Velo3D’s unique provider for Niobium C103 and different refractory alloy powders—together with molybdenum, tantalum, tungsten, and zirconium—and would be the most popular provider for titanium alloy powders.

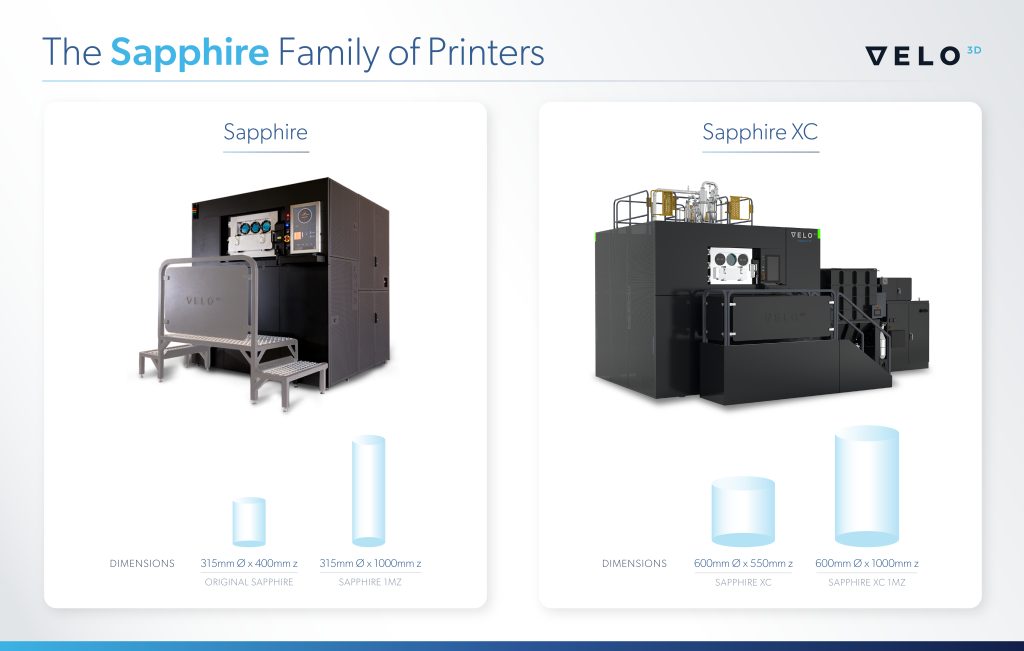

Velo3D will even qualify Amaero’s spherical powders and develop unique print parameters for each C103 and refractory alloys throughout all Velo3D Sapphire printers, in addition to for Amaero’s titanium alloy powder on new machine gross sales. The print parameters will likely be included with the 3D printing machine licensing, with none additional cost to clients.

Velo3D will use Amaero’s C103 and refractory alloy powders completely for all elements manufacturing, together with its Speedy Manufacturing Options (RPS) initiative, and can dedicate a Sapphire machine to manufacturing with C103 powder. Velo3D will even dedicate a Sapphire XC machine to manufacturing with titanium alloys. Moreover, Velo3D will completely provide Amaero’s C103, refractory, and titanium alloy powders on the market to its 3D printing machine clients.

Velo3D defined that this collaboration is a step towards supporting the re-shoring of superior manufacturing to america. Dr. Arun Jeldi, Velo3D’s CEO, commented: “Velo3D could be very excited to enter a long-term provide settlement with Amaero and to increase our proprietary print parameters to incorporate C103 and refractory alloy powders. As area and protection purposes evolve to require supplies that carry out in very excessive temperature and excessive situation environments, a proficient functionality to 3D print elements from C103 and refractory alloys is a vital and differentiating functionality.”

Amaero’s Strategic Growth and Dedication to U.S. Manufacturing

Hank J. Holland, Chairman and CEO of Amaero, emphasised that strengthening and increasing U.S.-based superior manufacturing and provide chain capabilities is central to the corporate’s technique. He famous that after many years of offshoring, current coverage efforts—significantly below the Trump Administration—have reprioritized industrial coverage to help each nationwide safety and financial development.

In response to vital vulnerabilities within the home provide chain, Amaero is making capital investments totaling roughly A$72 million via FY2026. This contains the commissioning of 4 state-of-the-art fuel atomizers, anticipated to offer an annual powder manufacturing capability exceeding 800 metric tonnes. The corporate has additionally allotted specialised manufacturing areas: one room and an EIGA Premium system for atomizing refractory alloys like niobium, molybdenum, tantalum, tungsten, and zirconium, and one other deliberate for titanium alloy manufacturing, with the aptitude to scale as much as 5 EIGA Premium atomizers.

“To attain the potential of steel additive manufacturing, it’s essential that we’ve a vibrant and financially sturdy home ecosystem that features 3D printing OEM firms, excessive throughput and technically proficient half producers and scalable, top quality, price aggressive spherical powders, “ mentioned Holland. “We look ahead to collaborating with Dr. Arun Jeldi and the Velo3D group to speed up adoption of steel 3D printing and to enhance the resiliency and scalability of home manufacturing.”

Strategic Provide Chain Partnerships

In March, PyroGenesis, a Canadian steel powder producer, formally confirmed Boeing because the aerospace OEM in its Ti64 steel powder qualification course of, ending months of hypothesis. P. Peter Pascali, President and CEO of PyroGenesis, emphasised the importance of this achievement. “PyroGenesis is proud to be within the last queue for reaching provider standing with Boeing, one of many largest, most notable, and most superior firms on this planet. What’s thrilling for PyroGenesis is that Boeing has proven itself to be a real innovator within the additive manufacturing area, having spent greater than three many years utilizing 3D printed elements.”

In February, Eire-based Croom Medical and US-based tantalum merchandise provider International Superior Metals (GAM) have developed a closed-loop provide chain strategy to develop using tantalum in 3D printing. By tackling the fabric’s processing challenges and making its use extra sustainable, the 2 firms are making certain a gentle, recyclable provide of tantalum powder for medical purposes. Their course of depends on Colibrium Additive’s M2 laser powder mattress fusion (LPBF) expertise to enhance printing effectivity, making tantalum a extra sensible choice for 3D printed implants.

What 3D printing tendencies do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals Refractory Powders. Photograph by way of Amaero.