Three years in the past, a consumer turned to Avner Dei, 3DEImention CEO, looking for a steel printer able to 5,000 components monthly. Whereas the Desktop Steel P50 met the construct necessities, its post-build depowdering proved laborious and costly. To get rid of this bottleneck, Avner partnered with engineering specialists to design a bespoke depowdering answer, chopping cleanup time in half and slashing working prices.

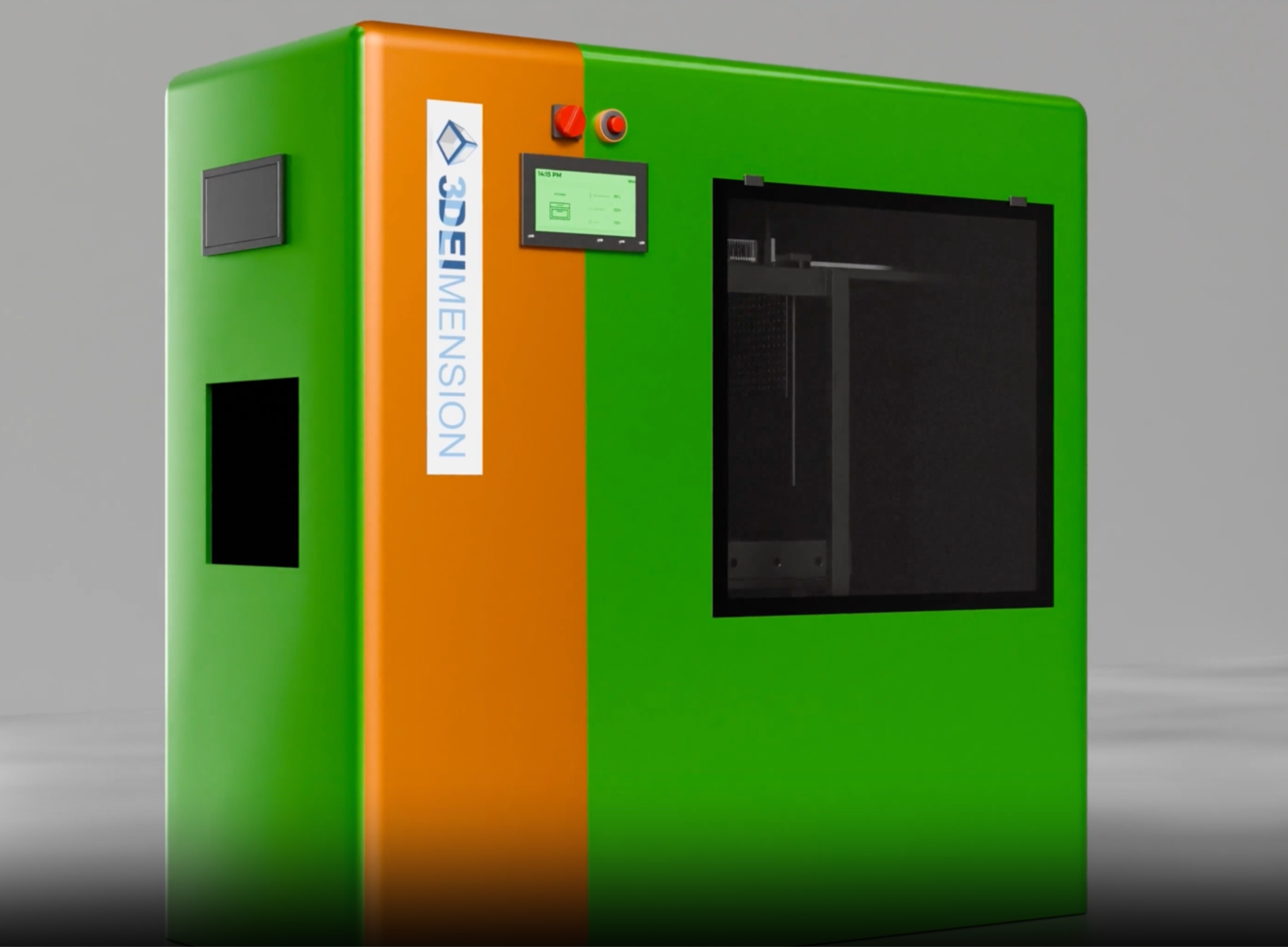

Right now, 3DEImention introduces an automatic answer for depowdering and extracting components from additive manufacturing print beds. Designed to deal with the bottleneck of guide powder elimination in mass-production environments, this technique reduces labor, improves half high quality, and recovers reusable powder in a single streamlined course of.

Automated Workflow from Print Mattress to Completed Half

3DEImention’s answer begins with a pre-programmed part-nesting course of wherein the construct top is split into layers. These layers are transferred to the depowdering machine, the place a motorized raise pushes the print-box ground as much as the predefined layer top into an elevation body that includes perforated aspect panels. Extra powder drains into designated assortment channels beneath the body, whereas a Teflon-coated partition is mechanically inserted to take care of powder distribution and stop injury to intricate surfaces. As soon as elevated, every layer undergoes focused vibration and managed air-pressure cleansing to dislodge adhering particles with out marring tremendous geometries. A robotic gripper arm then rotates and transfers the components onto sanitized trays, guaranteeing uniform cleansing and exact placement for downstream dealing with or inspection.

Precision Design, Sustainable Operation

Key improvements of the 3DEImention system embrace:

- Layer-by-Layer Depowdering: Programmable lifts sequentially current every printed layer to vibrating perforations, avoiding guide brushing and lowering cycle instances by over 50 p.c in comparison with customary workflows.

- Low-Friction Partitioning: The seamless motion of the Teflon-coated divider maintains a constant powder mattress top, defending delicate options and enabling uniform cleansing throughout complicated lattice constructions or tremendous overhangs.

- Automated Powder Restoration: Unfused powder is channeled into an enclosed assortment system the place vacuum-assisted suction captures as much as 70 p.c of fabric for instant reuse, chopping uncooked materials prices and environmental impression.

- Multi-Platform Compatibility: Whereas optimized for polymer SLS, the identical course of advantages steel powder mattress fusion (DMLS, SLM, EBM) and binder-jetting workflows in polymer, ceramic, or steel powders; automating what was as soon as a labor-intensive, guide cleanup step.

Measurable Beneficial properties in Manufacturing Effectivity

By automating the whole post-build sequence (layer separation, powder clearance, precision cleansing, and half extraction), 3DEImention’s system frees expert operators to give attention to high quality management and value-added duties. Producers report:

As much as 70% Discount in Depowdering Cycle Time: Sooner turnaround from print to last half.

As much as 30% Powder Reclamation: Vital financial savings on pricey polymer, ceramic, and steel powders.

Constant Half High quality: Managed cleansing parameters get rid of human variability, lowering half defects and rework.

Partnering and Funding Alternatives

Having validated their automated depowdering and part-extraction know-how in managed manufacturing environments, 3DEImention is now looking for strategic buyers and business companions to develop and deploy the primary totally operated industrial machine. They invite additive manufacturing service bureaus, gear integrators, and capital companions to collaborate on scaling this answer for international markets. Collectively, they will speed up adoption, develop performance, and customise the system to fulfill various manufacturing necessities.

For Inquiries and Additional Engagement

3DEImention’s automated depowdering answer integrates seamlessly with present print farms and post-processing cells. prospects can study extra or interact with the group by contacting Avner@3deimention.co.il or by visiting the web site.

About 3DEImention

3DEImention focuses on robotic post-processing gear for additive manufacturing. Combining experience in automation, supplies dealing with, and powder-bed applied sciences, the corporate delivers turnkey programs that improve throughput, high quality, and sustainability.