The 3D Printing Trade Yr in Evaluation continues with the most important tales from February.

After January’s volatility, the month introduced sharper definition to the place demand held, the place capital hesitated, and the place governance started to matter as a lot as know-how. Protection procurement hardened into probably the most dependable demand sign, capital flows grew to become selective moderately than expansive, and authorized and software program management points moved from background danger to operational actuality.

AI shifted from aspirational narrative towards embedded tooling, whereas development AM progressed alongside the trail from demonstration into compliance-driven procurement. Relatively than accelerating, the trade recalibrated. Put merely, February made clear the circumstances underneath which AM would function.

Sentiment narrows, priorities harden

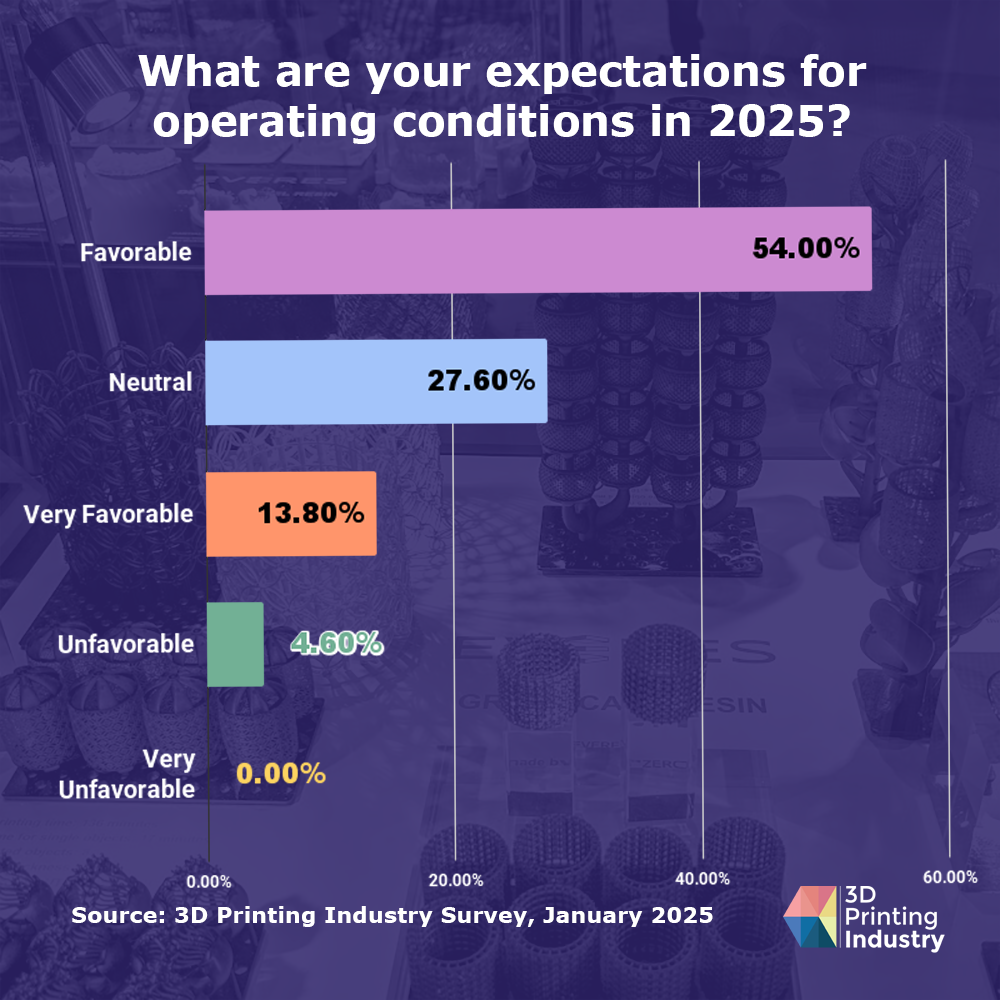

February’s framing got here from our 3DPI Govt Survey financial outlook, which provided a restrained however informative snapshot of trade circumstances. Govt sentiment remained web constructive, but the space between 2024 forecasts and precise outcomes uncovered persistent demand weak spot, notably for capital-intensive methods.

Enterprise circumstances improved, however to not the extent anticipated, whereas working circumstances revealed surprising friction. The sign was not collapse, however recalibration. Additive manufacturing superior inconsistently, with confidence concentrated in particular purposes moderately than throughout the market.

Inside that context, govt priorities narrowed. Protection, healthcare, aerospace, and vitality continued to face out as defensible segments, supported by qualification necessities, lengthy program lifecycles, and regulatory complexity. Software program, automation, and workflow integration appeared simply as central to govt planning as {hardware}.

The 3D printing tendencies for 2025 mirrored a shift away from growth narratives towards operational self-discipline. Consolidation, litigation, and geopolitical stress weren’t seen as mechanisms forcing readability round viable enterprise fashions and lifelike deployment paths.

In the meantime, our AI-focused survey translated February’s broader warning into operational phrases. Executives constantly positioned AI as an effectivity device moderately than a inventive one, emphasizing course of monitoring, design automation, simulation, qualification, and predictive upkeep.

The worth proposition was time saved, errors averted, and throughput stabilized, notably in manufacturing and fleet-level environments. Skepticism towards hype coexisted with sensible adoption, reinforcing the sense that AI was being absorbed into manufacturing infrastructure moderately than handled as a disruptive overlay.

In February, AI’s influence on additive manufacturing didn’t sign acceleration; it signaled standardization.

Protection demand crystallizes

This month, protection emerged as probably the most coherent demand sign for additive manufacturing.

The USAF funding in 3D printed UAS and the 3D printed loitering munition US Military trials positioned additively manufactured methods squarely inside formal analysis and procurement pathways. In each circumstances, AM was handled as an enabler of modularity, price management, and fast deployment in contested environments, as an alternative of an experimental manufacturing method.

That very same logic additionally prolonged to upkeep and coaching environments. The combination of Bambu Lab 3D printers for drone upkeep at Creech Air Pressure Base addressed spare half shortages, price pressures, and coaching delays moderately than novelty or innovation optics.

The selection of commercially accessible desktop methods successfully collapsed the boundary between shopper and navy provide chains. Pace, availability, and point-of-need fabrication mattered greater than platform pedigree.

Supplies technique accomplished the image throughout protection provide and manufacturing planning. Supernova Industries’ 3D printing energetic supplies protection contract confirmed AM being pushed into tightly regulated, higher-risk domains the place consistency and security are crucial.

In the meantime, Rolls-Royce’s RAF jet recycling into 3D printing materials and IperionX’s DoD titanium provide chain contract mirrored a systemic protection concentrate on materials sovereignty, circularity, and home resilience. Throughout these developments, protection patrons confirmed little concern for AM ideology. Their priorities have been velocity, provide safety, and deployability.

Funding with circumstances connected

The month additionally noticed capital nonetheless flowing into AM, however in a much more selective and conditional kind. The Stratasys $120 million Fortissimo funding offered stability sheet reinforcement at a premium valuation, but it touchdown alongside Stratasys preliminary This autumn 2024 outcomes underscored ongoing stress on capital gear demand and continued working losses underneath GAAP measures.

The timing mattered as a result of the funding strengthened liquidity and governance alignment, nevertheless it didn’t resolve structural questions round profitability, nor did it insulate the corporate from legacy acquisition danger tied to earlier development methods.

These dangers have been made express by the continuing Origin earn-out litigation, which remained unresolved because the court docket weighed arbitration vs. trial. The dispute highlighted how acquisition-era deal constructions proceed to floor as liabilities.

The same reckoning was seen via Nano Dimension CEO shareholder letter amounting to a public reset. The corporate acknowledged that consolidation with out operational readability, disciplined capital allocation, or investor belief had didn’t ship worth, regardless of vital capital raised throughout peak market enthusiasm. Governance reform, expense management, and potential restructuring changed expansion-driven narratives.

In contrast, the ICON $56 million Collection C funding stood aside, not as a result of it contradicted the development, however as a result of it match a narrower investor narrative. Building 3D printing continued to draw capital the place scale, public infrastructure, and authorities partnerships remained legible, together with protection and house. Even right here, funding adopted layoffs and a tighter concentrate on deployable methods moderately than broad experimentation.

Capital exercise this time round signaled repricing moderately than retreat, with capital accessible however not affected person, narrative-driven, or tolerant of ambiguity.

Management layers transfer upfront

February surfaced regulation, IP, and platform management as first-order trade constraints moderately than background noise.

The Origin shareholders lawsuit towards Stratasys and the Steady Composites lawsuit after Markforged dispute mirrored post-acquisition and post-litigation cleanup, the place earn-outs, contingency constructions, and arbitration clauses have been being actively contested moderately than quietly settled. These circumstances pointed to a maturing sector by which monetary engineering from the final cycle was being stress-tested in court docket.

On the platform degree, Stratasys vs Bambu Lab lawsuit replace underscored how management over distribution, {hardware} options, and IP had develop into a aggressive lever. The dispute was not solely about alleged infringement however about jurisdiction, subsidiary duty, and who constitutes a major participant in a world {hardware} enterprise. This highlighted that IP enforcement was now getting used to outline market boundaries as low-cost desktop methods scaled quickly.

Software program management sharpened this dynamic additional. Bambu Lab’s firmware modifications and Orca Slicer rejecting Bambu Join uncovered rising rigidity between security-driven platform consolidation and ecosystem belief rooted in open tooling.

Collectively, these episodes instructed that competitors in AM was not confined to machines or supplies. Management over software program, customers, and integration pathways had develop into a constraint that firms now needed to handle as rigorously as price or efficiency.

Software program infrastructure beats novelty

Software program bulletins strengthened that compute and workflow infrastructure, is the place AM funding stays defensible.

One notable instance was the Authentise Autodesk additive manufacturing collaboration functioning as consolidation moderately than growth.

Design validation, slicing, nesting, scheduling, and execution have been unified inside a single, version-controlled manufacturing setting. In a weak demand cycle, continuity of information and governance throughout design and manufacturing outweighed incremental function additions.

Moreover, the nTop acquisition to speed up CFD pointed in the identical path. By embedding GPU-native fluid simulation into its computational design platform, nTop decreased iteration time in aerospace and turbomachinery, the place simulation constancy underpins qualification and efficiency claims.

Eradicating meshing and accelerating solver speeds focused a recognized workflow bottleneck moderately than increasing product scope. Earlier integrations with Nvidia strengthened compute effectivity as a prerequisite for credible design automation.

These strikes aligned carefully with February’s AI dialogue. Intelligence mattered solely when embedded in manufacturing software program, simulation, and course of management, not as standalone instruments. As certification stress and price sensitivity elevated, software program that decreased friction between design, simulation, and execution shifted from non-compulsory functionality to enabling infrastructure.

Building meets procurement actuality

Lastly, February confirmed development 3D printing transferring decisively from demonstration to procurement. ICON’s $56 million increase mattered much less as a capital occasion than as reinforcement of a mannequin already validated by institutional patrons, most clearly the U.S. Division of Protection (DoD).

The 3D printed barracks at Fort Bliss framed development AM as compliant navy infrastructure, constructed in accordance with the DoD’s up to date Unified Amenities Standards, which now formally embrace AM strategies.

On this context, funding adopted proof of deployability moderately than imaginative and prescient alone. Governments appeared as early clients, signaling that scale, repeatability, and compliance had overtaken novelty because the circumstances underneath which development AM now superior.

Classes from February

By the tip of the month, February reframed AM as an trade adjusting to limits moderately than chasing risk. Institutional patrons set the tempo, capital demanded self-discipline, and authorized, software program, and information management emerged as aggressive constraints.

The month’s occasions confirmed AM changing into extra legible and fewer forgiving, with fewer narratives tolerated and fewer shortcuts accessible. Progress was outlined by deployability, compliance, and integration moderately than novelty or scale guarantees. On this sense, February didn’t sign contraction, however maturation.

The 3D Printing Trade Awards are again. Make your nominations now.

Do you use a 3D printing start-up? Attain readers, potential buyers, and clients with the 3D Printing Trade Begin-up of Yr competitors.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals a US solider launching a loitering munition. Picture through Sgt. Gregory T. Summers, twenty second Cellular Public Affairs Detachment/US Military.