Oak Ridge Nationwide Laboratory (ORNL) researchers have demonstrated that 3D-printed metallic molds provide vital benefits for producing massive composite parts for automotive manufacturing. The examine, carried out at ORNL’s Manufacturing Demonstration Facility (MDF), discovered that large-scale additive manufacturing can create advanced metallic molds extra effectively than conventional tooling strategies. This method might assist speed up the adoption of light-weight composite supplies in car manufacturing.

“This type of know-how might help reindustrialize the U.S. and increase its competitiveness by creating smarter, sooner methods to construct important instruments,” stated lead researcher Andrzej Nycz with ORNL’s Manufacturing Robotics and Controls group. “It brings us nearer to an automatic, clever manufacturing course of.”

Conventional metallic tooling entails subtracting materials from massive metal blocks, which may take away as much as 98% of the unique materials and generate substantial waste. In distinction, additive manufacturing deposits metallic layer by layer utilizing broadly obtainable welding wire, decreasing waste to roughly 10%. The method additionally permits the creation of extra advanced mould geometries, corresponding to inner heating channels, that might be troublesome to realize with standard machining.

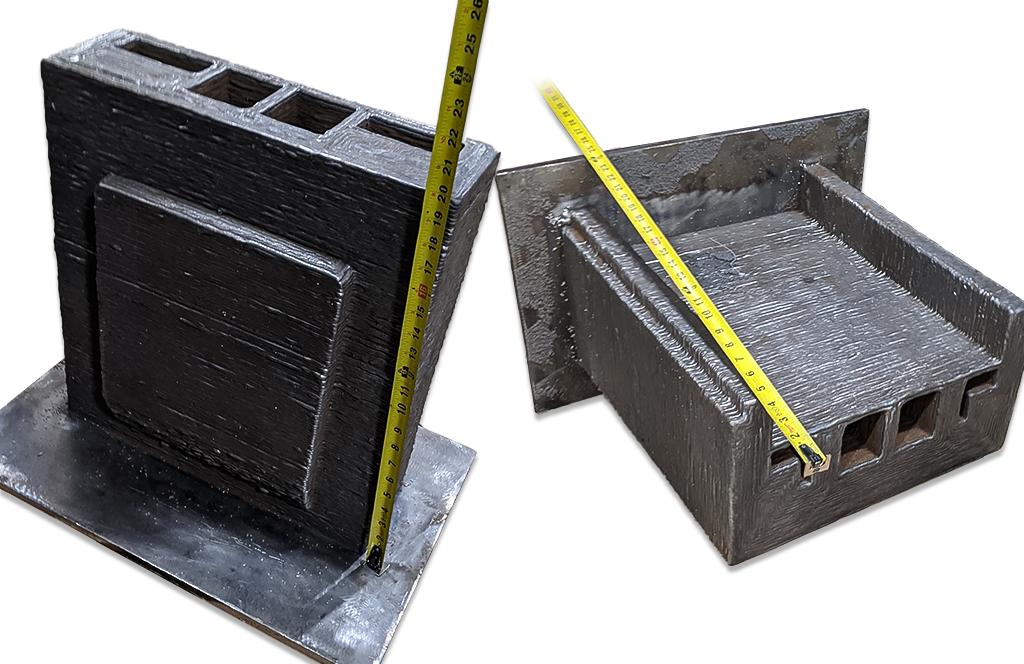

The analysis crew partnered with Collaborative Composites Options (CCS) to check the idea by 3D printing a big battery enclosure mould with intricate inner options. Utilizing gasoline metallic arc welding (GMAW) additive manufacturing at Lincoln Electrical Additive Options, they printed two near-net-shape dies from stainless-steel ER410 wire. The crew utilized a specialised toolpath technique to scale back weight whereas sustaining energy.

Evaluation confirmed that the lightweighted mould met structural efficiency necessities, validating the feasibility of additive manufacturing for high-performance manufacturing tooling. The challenge was funded by the Division of Power’s Superior Supplies and Manufacturing Applied sciences Workplace (AMMTO), with extra researchers from Composite Purposes Group, ORNL, and Lincoln Electrical Additive Options contributing to the work.

Supply: ornl.gov